Explosive atmospheres usually occur in process engineering plants such as silos, elevators, mixers, mills and conveyors. In the presence of effective internal or external ignition sources, there is a risk of explosion in the respective plant as well as a risk of propagating of the explosion into connected plant components. Explosion protection is concerned with reducing the effects of an explosion and is the central, most frequently applied explosion protection concept. The explosion protective measures include conventional explosion venting using explosion vents, flameless venting, explosion isolation and explosion suppression. But which protective measure is applied to which plant component?

Plant example 1: Filters

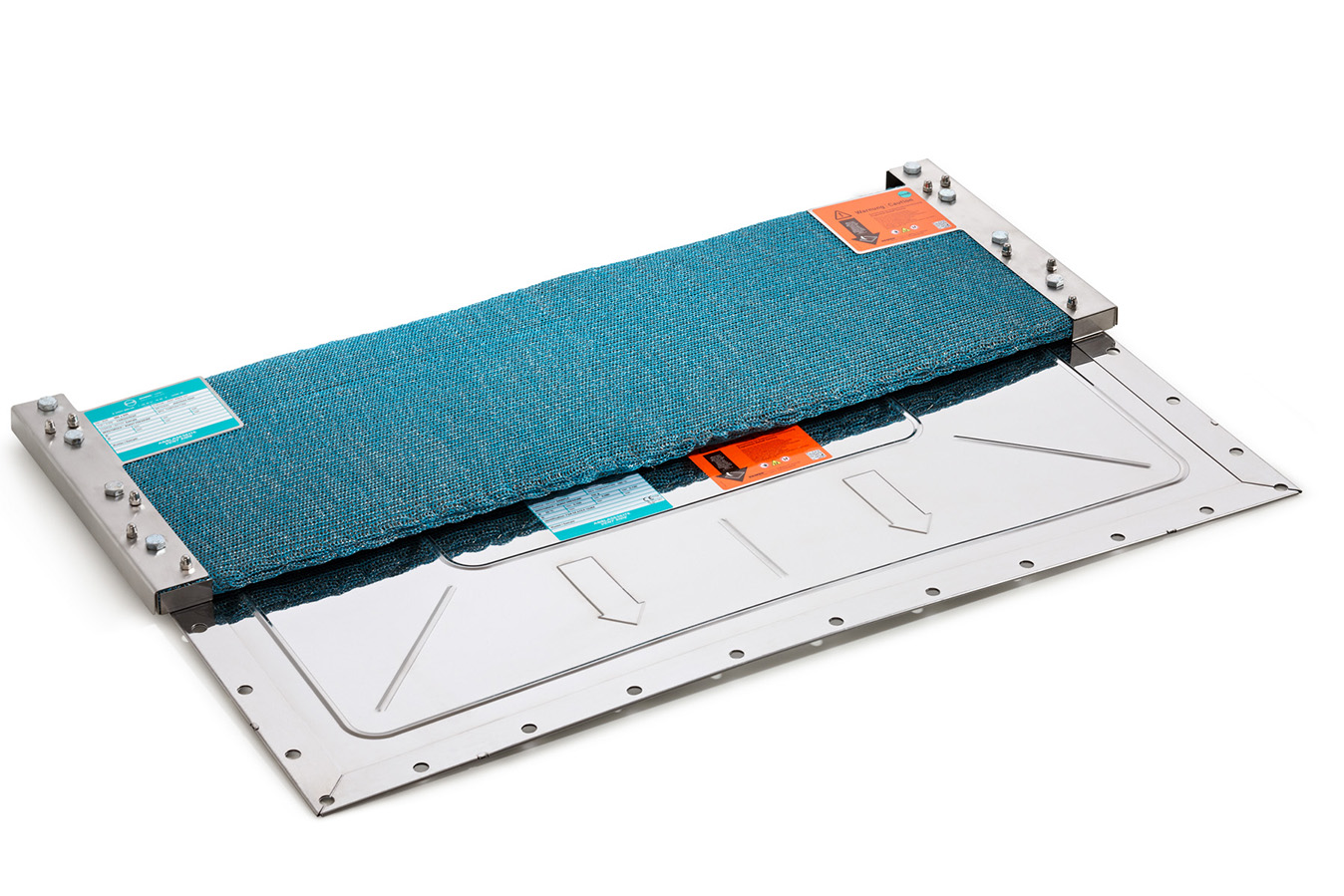

The risk of explosion is particularly high in filter systems. The very fine dust is distributed in the filter and can trigger an explosion if an ignition source is present. Filters indoors are therefore protected with flameless venting, filters outdoors with explosion vents. If there are traffic routes for people and vehicles in the vicinity of explosion venting, add-on modules for explosion vents such as the TARGO-VENT are used. TARGO-VENT limits the opening angle of the explosion vent and directs explosion pressure, flames and heat into defined areas. In this way, safety areas can be reduced.

Explosive atmospheres usually occur in process engineering plants such as silos, elevators, mixers, mills and conveyors. In the presence of effective internal or external ignition sources, there is a risk of explosion in the respective plant as well as a risk of propagating of the explosion into connected plant components. Explosion protection is concerned with reducing the effects of an explosion and is the central, most frequently applied explosion protection concept. The explosion protective measures include conventional explosion venting using explosion vents, flameless venting, explosion isolation and explosion suppression. But which protective measure is applied to which plant component?

Plant example 1: Filters

The risk of explosion is particularly high in filter systems. The very fine dust is distributed in the filter and can trigger an explosion if an ignition source is present. Filters indoors are therefore protected with flameless venting, filters outdoors with explosion vents. If there are traffic routes for people and vehicles in the vicinity of explosion venting, add-on modules for explosion vents such as the TARGO-VENT are used. TARGO-VENT limits the opening angle of the explosion vent and directs explosion pressure, flames and heat into defined areas. In this way, safety areas can be reduced.

Plant example 2: Spray dryers

Dust, which is often flammable, and oxygen are always stirred-up in spray dryers, whether in the food, chemical or pharmaceutical industry. The most frequent ignition sources in spray dryers are glowing embers, damage to rotary nozzles, hot bearings or sparks due to an imbalance.

Take particular care to protect yourself from “overengineering”. Which protection measure makes sense for your plant depends on the volume of the spray dryer to be protected, its respective installation site and strength.

Spray dryers are usually protected with a combination of explosion isolation systems and conventional venting using explosion vents. Flameless venting is used when free venting is not possible.

The special EGV HYP and ERO explosion vents are used in hygienically demanding processes. The connecting pipelines are usually isolated. The aim is to close these pipelines in the event of an explosion in order to prevent the propagation of pressure and flames and thus protect adjacent plant components.

Plant example 3: Conveyors such as elevators

There are various venting options for the wide range of conveyors. Due to the functional and design-based conditions, elevators represent a special source of danger. Conveying a large amount of (combustible) bulk material carries a high risk of explosion. As with the previously mentioned plants, the elevator legs are usually protected outdoors with explosion vents and indoors with the REMBE Q-Box or the REMBE Q-Ball.

Depending on the conditions at the installation site, a combination of conventional and flameless venting can also be the right safety concept. Quench valves can be installed to prevent explosion propagation via connected aspiration lines. The REMBE Q-Bic extinguishing barrier is usually used to isolate the conveyors upstream or downstream.

Plant example 4: Silos

Silos, in particular, are critical plant components when it comes to explosion protection. An explosive dust-air mixture prevails when filling a silo.

If it is not possible to exclude all potential ignition sources, silos must be protected constructively. Outdoors, silos are generally vented with explosion vents – different types can be used depending on the type of filling. Indoors, the REMBE Q-Box or the REMBE Q-Rohr will be installed for flameless venting.

As a rule, explosion isolation is implemented using quench valves. These completely close the pipelines within a few milliseconds; the explosion cannot propagate further.

Conclusion: The explosion protection concept can only be safe and economical if the entire system is observed and the individual protective measures are coordinated. This requires a systematic approach as well as observance of system-specific boundary conditions and knowledge of methods for assessing safety-related parameters.

www.rembe.de