Working at height is a risky business, and the wind energy sector is no exception. In 2021/22 there were 29 work-related fatalities due to falls from a height in the UK – representing almost 24% of all worker deaths.[i] While total industry deaths are falling year-on-year, the people behind these statistics remind us that there is still a long way to go.

For those responsible for the safety of their workers, choosing appropriate systems is a huge responsibility when there is so much to consider. Here, Tim Bissett, Technical Manager at MSA Safety, explores the importance of adhering to the latest safety standards and explains some important considerations users and installers should be looking out for when it comes to choosing an appropriate vertical fall protection system for wind turbines.

Being proactive about safety

In 2020, over 500 safety incidents were reported at the UK’s onshore wind farms.[ii] Maintaining turbines can see workers having to climb as heigh as 30m at a time, which along with the often-limited access and frequent requirement to work in a confined space can contribute to workers’ risks. Therefore, being proactive about safety includes getting all relevant teams fully trained, competent, and comfortable working in these conditions, as well as knowledgeable about the chosen fall protection system and how it operates. Doing this will help to minimise the risk to workers.

Complying with safety standards

Safety standards vary across different locations and legislations, so it’s important to be aware of which standards you should be paying attention to. For example, for fall protection equipment certifications in Europe it’s EN standards. The EN standard used to apply in the UK as well but, following Brexit, the UKCA mark is now required as of 1 January 2023.

Even after initial selection consider regular checks of your fall protection systems for elements that could include:

- The compliance certificates of your equipment and systems for expiry dates and that the life of your system is still in date.

- You have regular inspections scheduled, including to check wear and tear.

Having simple checks like these in place will help you to increase your control over the systems used by your workforce.

And if you’re in the UK and Europe, to enhance the health and safety of your wind turbine workers, consider whether your safety equipment adheres to EN 353-1:2018 (EN 353-1:2014+A1:2017) - the newest update to fall protection system requirements.

- Some key features of EN 353-1:2018 that companies can check, depending on their circumstances, are:

- Dynamic performance testing – to check the maximum arrest force

- Cold condition testing – checking locking function in cold conditions

- Minimum distance testing – to replicate the user falling close to the anchor line

- Fall back testing – which replicates the user falling back and down

- Guide bracket testing – looking at the strength of the bracket and anchor line and the locking function of a fall arrester in the event of a fall

- Sideway fall testing – to replicate the user falling in a sideways direction

- Leaning angle testing – considering the locking function of the fall arrester with the anchor line leaning forward and sideways

- Static strength requirements - testing to check the overall strength of the system.

As this list shows, the EU type-examination process for EN 353-1:2018 is rigorous and it incorporates several dynamic tests that covered many scenarios. Updating to this standard can help give your workers added confidence that their safety at height is a top priority.

Ease of use

Another element to consider when choosing fall protection systems for wind turbines, is how simple it is for workers to use. After all, there are advantages to systems that workers understand fully and will use. These fall protections systems should balance the users’ accessibility with their needs for relevant applications, such as considering whether a restriction or complex process reduces users’ risk.

At MSA Safety, We Know What’s At Stake

Keeping workers safe is a top priority and as safety professionals, it’s our mission to help make sure that workers go home to their family at the end of the working day. That’s why compliance and product testing are at the core of what we do.

For more information and resources on fall protection systems, please visit MSA Safety.

This article can also be found in the issue below.

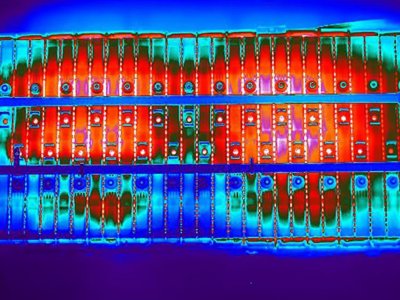

For hazardous applications such as establishing the health of electrical components at a substation, the ability to measure temperature accurately over a distance is critical. Achieving this depends on several factors and two of the most important are the resolution of the detector and the chosen camera lens.

For hazardous applications such as establishing the health of electrical components at a substation, the ability to measure temperature accurately over a distance is critical. Achieving this depends on several factors and two of the most important are the resolution of the detector and the chosen camera lens.

Slips, trips and falls are often seen as a common sense issue, if they’re thought about at all. Pay attention, don’t be stupid, look where you’re going - in other words, keep your wits about you, and you should be smart enough to avoid any danger. What few realise is the extent to which slips, trips and falls forego logic, and make a mockery of common sense solutions.

Slips, trips and falls are often seen as a common sense issue, if they’re thought about at all. Pay attention, don’t be stupid, look where you’re going - in other words, keep your wits about you, and you should be smart enough to avoid any danger. What few realise is the extent to which slips, trips and falls forego logic, and make a mockery of common sense solutions.