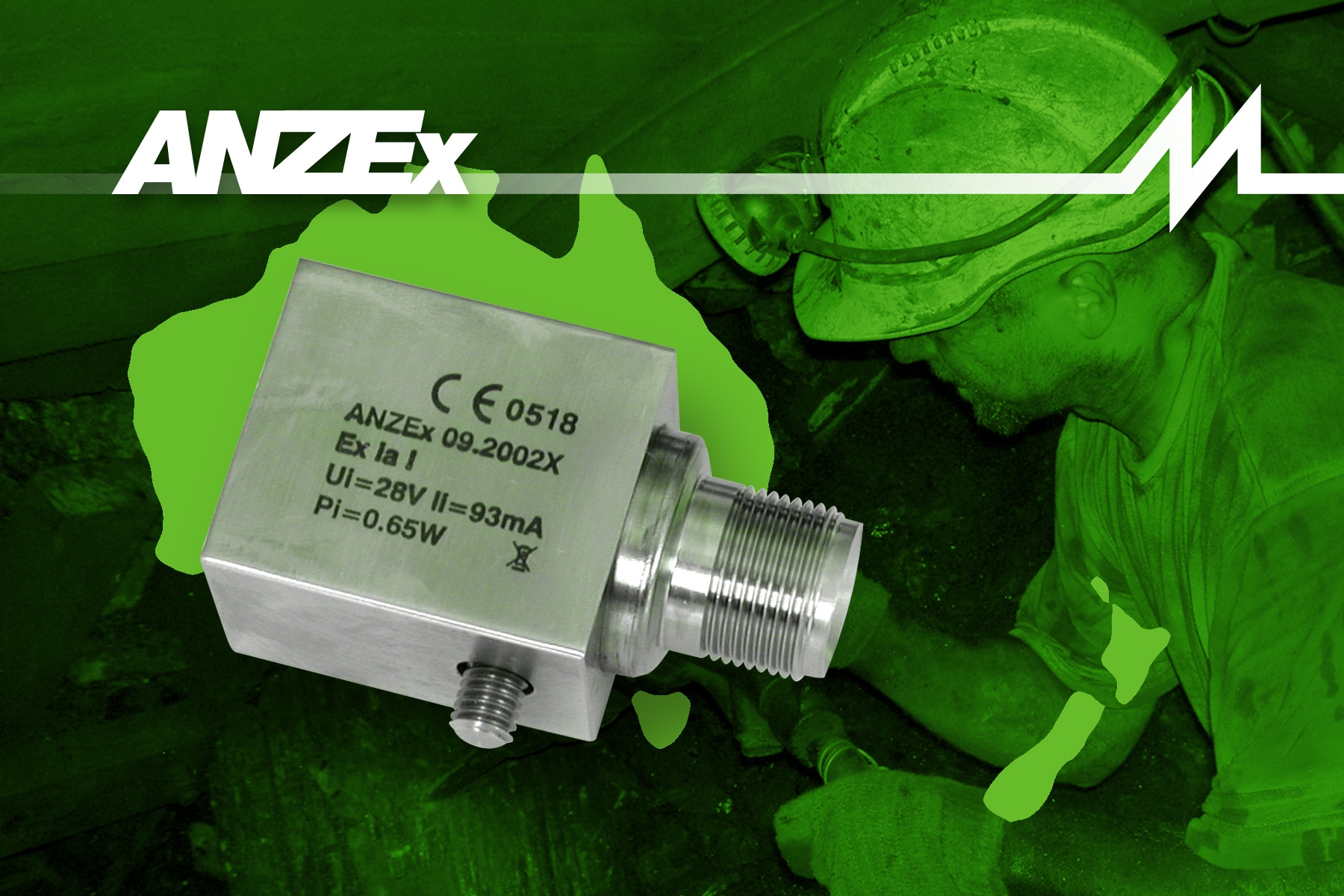

Monitran’s Group I intrinsically safe sensors are awarded ANZEx for use in mining applications in Australia and New Zealand.

Monitran’s Group I intrinsically safe sensors are awarded ANZEx for use in mining applications in Australia and New Zealand.All of Monitran’s Group I intrinsically safe accelerometers and velocity transducers have been approved by certification body Simtars to ANZEx for use in mining applications throughout Australia and New Zealand. This certification is in addition to the (EU) ATEX and (International) IECEx approvals Monitran’s Group I sensors already possess.

Andy Anthony, Monitran’s Operations Director, comments: “Many countries, whilst acknowledging international standards like IECEx, still impose their own standards for certain applications. We sought ANZEx in response to requests from end-users based in Australia and New Zealand, and companies based elsewhere wishing to supply machinery into these countries.”

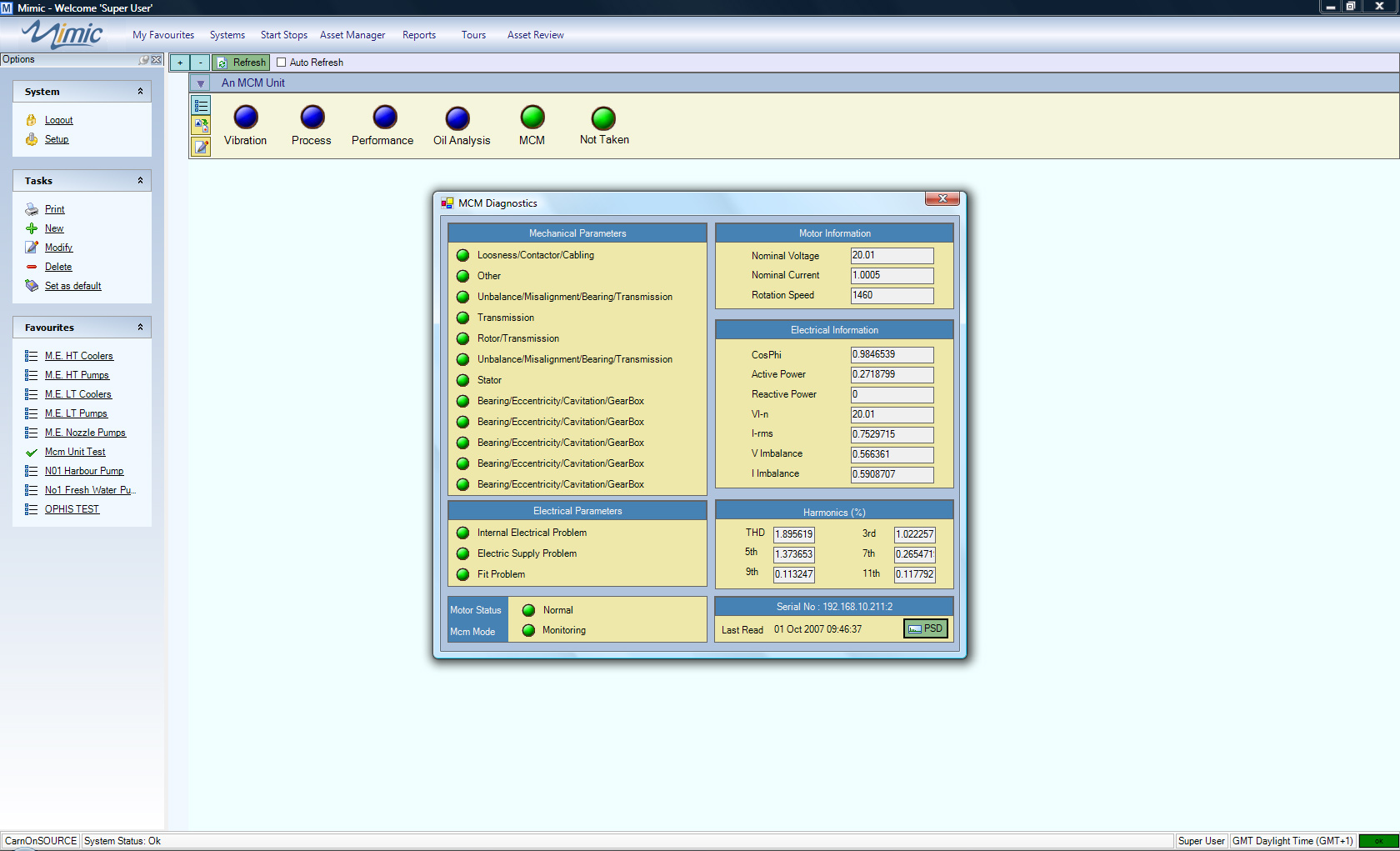

.jpg) By: Ernesto Wiedenbrüg, Baker Instrument Company, an SKF Group Company

By: Ernesto Wiedenbrüg, Baker Instrument Company, an SKF Group Company The contribution of maintenance to an organisation is unfortunately too often not fully understood until something goes wrong e.g. a failure of a significant plant item or asset.This will inevitably result in a consequential loss through the inability to produce or provide a service or the occurrence of an environmental health, safety or quality incident.

The contribution of maintenance to an organisation is unfortunately too often not fully understood until something goes wrong e.g. a failure of a significant plant item or asset.This will inevitably result in a consequential loss through the inability to produce or provide a service or the occurrence of an environmental health, safety or quality incident.  It is common knowledge that a range of Condition Monitoring (CM) techniques are available such as Vibration Analysis, Oil & Wear Debris Analysis, Thermography and Acoustic Emission. Each of these techniques has its own particular areas of strength and in this regard the Acoustic Emission (AE) technique has the noted advantage of giving real time information with early sensitivity to faults and applicability to a wide range of rotational speeds including slowly rotating (source : ISO 22096).

It is common knowledge that a range of Condition Monitoring (CM) techniques are available such as Vibration Analysis, Oil & Wear Debris Analysis, Thermography and Acoustic Emission. Each of these techniques has its own particular areas of strength and in this regard the Acoustic Emission (AE) technique has the noted advantage of giving real time information with early sensitivity to faults and applicability to a wide range of rotational speeds including slowly rotating (source : ISO 22096). Sonatest are proud to launch the new Corrosion Wheelprobe, which has been specifically designed for Pipeline Corrosion Mapping applications. Continuing the proven success of Sonatest’s WheelProbe range, this new model is proving to be unrivalled in the field of corrosion mapping in terms of speed and ease of use, in addition to achieving excellent results.

Sonatest are proud to launch the new Corrosion Wheelprobe, which has been specifically designed for Pipeline Corrosion Mapping applications. Continuing the proven success of Sonatest’s WheelProbe range, this new model is proving to be unrivalled in the field of corrosion mapping in terms of speed and ease of use, in addition to achieving excellent results. Problem: Wind turbines by their nature are located in remote locations. Daily monitoring of systems is often an impractical solution.

Problem: Wind turbines by their nature are located in remote locations. Daily monitoring of systems is often an impractical solution.

SPM Instrument, now presents a new portable instrument for on-site vibration measurement and assessment. VibChecker is a cost-effective and user friendly addition to the SPM line of entry-level instruments for condition monitoring, where BearingChecker for bearing measurement is already a successful member.

SPM Instrument, now presents a new portable instrument for on-site vibration measurement and assessment. VibChecker is a cost-effective and user friendly addition to the SPM line of entry-level instruments for condition monitoring, where BearingChecker for bearing measurement is already a successful member. Send for your free pocket guide to TPM and see how you can greatly improve the condition and performance of your company assets and operational processes using shop floor based teams. The guide has been produced by Roy Davis, probably the most experienced TPM implementer in the UK.

Send for your free pocket guide to TPM and see how you can greatly improve the condition and performance of your company assets and operational processes using shop floor based teams. The guide has been produced by Roy Davis, probably the most experienced TPM implementer in the UK.