Brenntag Oil & Gas cleans Total pipeline with compressed air and achieves a lower explosion level of

Brenntag Oil & Gas Europe recently cleaned a 140 km / 60.96 cm crude transport line at Total Refinery in Vlissingen, The Netherlands, with N-SPEC

Brenntag Oil & Gas Europe recently cleaned a 140 km / 60.96 cm crude transport line at Total Refinery in Vlissingen, The Netherlands, with N-SPEC

Brenntag Oil & Gas Europe recently cleaned a 140 km / 60.96 cm crude transport line at Total Refinery in Vlissingen, The Netherlands, with N-SPEC

Brenntag Oil & Gas Europe recently cleaned a 140 km / 60.96 cm crude transport line at Total Refinery in Vlissingen, The Netherlands, with N-SPEC

The energy bill for compressed air at a UK car [ manufacturing plant was around

The energy bill for compressed air at a UK car [ manufacturing plant was around

Oil-free condensates and condensates from gas compressors are normally highly aggressive. However, they cannot attack the Bekomat 13 CO PN 40. The excellent corrosion resistance of the device is due to a 50 micron hard coating, which gives a ceramic structure to the surface of its aluminium housing.

Oil-free condensates and condensates from gas compressors are normally highly aggressive. However, they cannot attack the Bekomat 13 CO PN 40. The excellent corrosion resistance of the device is due to a 50 micron hard coating, which gives a ceramic structure to the surface of its aluminium housing.

The Bekomat 13 CO PN 40 condensate drain is designed for application with compressors up to 30 m

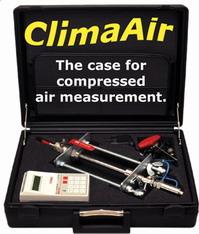

The hand-held ClimaAir Instrument is used in conjunction with the CombiSensor to calculate compressed air flow in m

The hand-held ClimaAir Instrument is used in conjunction with the CombiSensor to calculate compressed air flow in m

For the first time ever, it is now possible to monitor the quality of compressed air by online measurement of the residual oil content.

For the first time ever, it is now possible to monitor the quality of compressed air by online measurement of the residual oil content.

Beko have introduced an oil control measuring system, Oil Control enables permanent monitoring of the oil content of the compressed air flow, either centrally or at individual points. The system measures down to 0.001 mg/m3 and is therefore suitable for use with the new food industry guidelines, as well as for medical and other critical applications.

The sensitivity of the sensor guarantees an early detection of any increase in the oil content, for example caused by failed filters. Consequential damage to machinery and products is thus successfully prevented, and the production medium

Earlier this year the university of Leeds held a training course entitled "Pharmaceutical Medical Gas Testing". This was held at the new training facility of Midland Medical Services Ltd, Rowley Regis, West Midlands. 32 delegates were in attendance for 5 days.

Earlier this year the university of Leeds held a training course entitled "Pharmaceutical Medical Gas Testing". This was held at the new training facility of Midland Medical Services Ltd, Rowley Regis, West Midlands. 32 delegates were in attendance for 5 days. Compressed-air users know the problem: the legal regulations applying to the processing of unavoidably accumulating condensate are becoming ever more strict and comprehensive. Simultaneously, the costs need to remain within economically justifiable limits. Decentralised processing of condensates directly at the point of origin has therefore established itself as the most suitable and above all, the most-effective solution. This is exactly what the new Owamat oil-water separator generation made by Beko does better than ever before.

Compressed-air users know the problem: the legal regulations applying to the processing of unavoidably accumulating condensate are becoming ever more strict and comprehensive. Simultaneously, the costs need to remain within economically justifiable limits. Decentralised processing of condensates directly at the point of origin has therefore established itself as the most suitable and above all, the most-effective solution. This is exactly what the new Owamat oil-water separator generation made by Beko does better than ever before.

The completely new Owamat devices meet the legal requirements on the introduction of purified water into the municipal wastewater system. This has been confirmed by the national approval of the

Compressed air that is used for medical treatments has to meet special requirements in terms of compressed air quality, availability and patient safety. With Medbac, permanent monitoring of the compressed air quality has now become reality. This makes it easy to comply with the mandatory limit values stipulated in the European Pharmacopoeia.

Compressed air that is used for medical treatments has to meet special requirements in terms of compressed air quality, availability and patient safety. With Medbac, permanent monitoring of the compressed air quality has now become reality. This makes it easy to comply with the mandatory limit values stipulated in the European Pharmacopoeia.

The modular Medbac system has been designed specifically for monitoring the purity of on-site produced breathing air in hospitals, specifically Oxygen, Carbon Monoxide and Carbon Dioxide, Sulpher Dioxide, Nitrous gases, water and oil vapour. Thanks to its excellent detection sensitivity, malfunctions are spotted immediately. As a result, patients are protected and medical equipment is not damaged. Medbac guarantees the safe production of

Compressed air drying is a decisive factor for the process reliability in the production and for the operational reliability in compressed-air systems. Therefore, BEKO has offered a comprehensive program regarding compressed-air drying for many years. Amongst others, the cold-regenerated Drypoint AC adsorption dryers for volume flows up to 1500 m3/h are highly regarded. However, for some compressed-air users, this is not enough. With the heat-regenerated BEKO Everdry adsorption dryers for volume flows up to 20,000 m3/h (and more), Beko offers standardised system solutions for compressed-air drying on a grand scale.

Compressed air drying is a decisive factor for the process reliability in the production and for the operational reliability in compressed-air systems. Therefore, BEKO has offered a comprehensive program regarding compressed-air drying for many years. Amongst others, the cold-regenerated Drypoint AC adsorption dryers for volume flows up to 1500 m3/h are highly regarded. However, for some compressed-air users, this is not enough. With the heat-regenerated BEKO Everdry adsorption dryers for volume flows up to 20,000 m3/h (and more), Beko offers standardised system solutions for compressed-air drying on a grand scale.