Profitability is everything in a competitive environment. BEKO Technologies, the market leaders in compressed air technology, boast a comprehensive program of systems designed to save energy and improve efficiency in the application of compressed air.

Profitability is everything in a competitive environment. BEKO Technologies, the market leaders in compressed air technology, boast a comprehensive program of systems designed to save energy and improve efficiency in the application of compressed air.From BEKO’s perspective, one of the key areas requiring attention in most production fa-cilities is the acquisition and analysis of data regarding compressed air use. Indeed, many plant managers are simply unaware of how much air is used or how much each cubic me-tre of air costs.

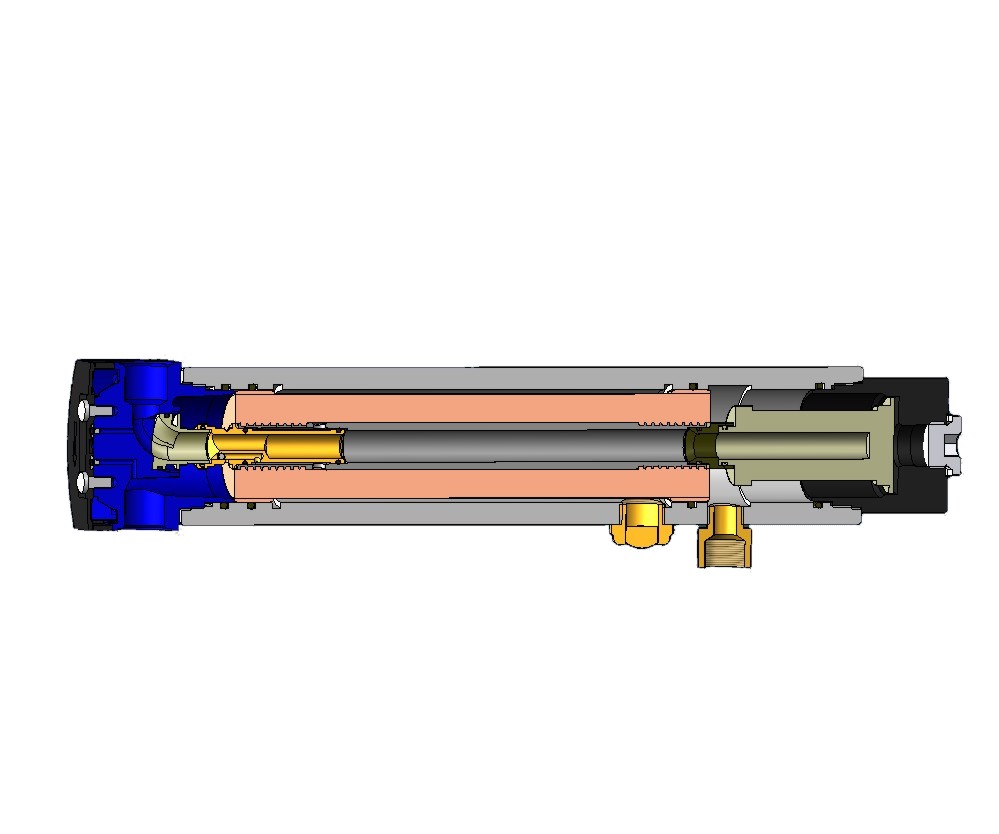

The DRYPOINT® M PLUS membrane dryers with an integrated nanofilter made by BEKO TECHNOLOGIES, Neuss, Germany, have proven themselves particularly useful when employed downstream of compressors (in satu-rated compressed air which is warmer than the ambient air).

The DRYPOINT® M PLUS membrane dryers with an integrated nanofilter made by BEKO TECHNOLOGIES, Neuss, Germany, have proven themselves particularly useful when employed downstream of compressors (in satu-rated compressed air which is warmer than the ambient air).  To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group.

To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group.  To ensure customers can immediately comply with current regulations, Airchannel, the UK’s leading independent compressed air specialist, is providing an integrated Written Scheme of Examination (WSE) as part of its complete service.

To ensure customers can immediately comply with current regulations, Airchannel, the UK’s leading independent compressed air specialist, is providing an integrated Written Scheme of Examination (WSE) as part of its complete service. Michell Instruments’ MDM300 advanced dew-point hygrometer can save engineers weeks of waiting time each year.

Michell Instruments’ MDM300 advanced dew-point hygrometer can save engineers weeks of waiting time each year. To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group. As the world leader in glass bead impact technology, Potters is continually developing and refining its manufacturing procedures to ensure consistently high quality glass spheres, which are tested to conform to every market specification.

To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group. As the world leader in glass bead impact technology, Potters is continually developing and refining its manufacturing procedures to ensure consistently high quality glass spheres, which are tested to conform to every market specification. To help businesses cope with the current tough economic conditions, Airchannel Limited is launching PaySmart, a new way of financing a company’s compressed air needs. As well as new equipment, PaySmart covers the fitting of new pipework and ancillaries along with full installation.

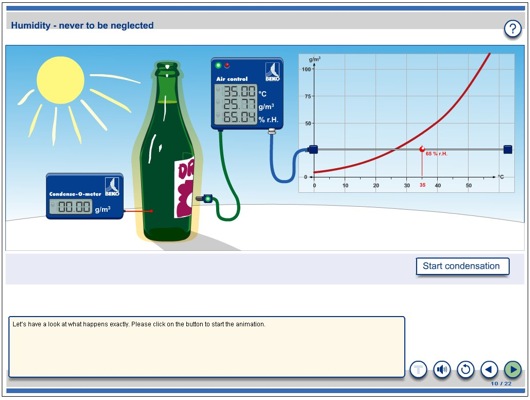

To help businesses cope with the current tough economic conditions, Airchannel Limited is launching PaySmart, a new way of financing a company’s compressed air needs. As well as new equipment, PaySmart covers the fitting of new pipework and ancillaries along with full installation. BEKO Technologies is further extending its product range by launching their first e-learning course - “The Basics of Compressed Air Technology”. This innovative course is now available to all customers and partners, giving them the chance to share and benefit from BEKO’s vast experience in compressed air.

BEKO Technologies is further extending its product range by launching their first e-learning course - “The Basics of Compressed Air Technology”. This innovative course is now available to all customers and partners, giving them the chance to share and benefit from BEKO’s vast experience in compressed air. More and more often, industrial applications expect mobility and flexibility from compressed-air processing. For example for the employment at different sites or outdoors. A solution to that is the installation of complete compressed-air stations in transportable sea containers. These mobile performance centres make special demands on the technology applied, in particular as far as compressed-air drying is concerned.

More and more often, industrial applications expect mobility and flexibility from compressed-air processing. For example for the employment at different sites or outdoors. A solution to that is the installation of complete compressed-air stations in transportable sea containers. These mobile performance centres make special demands on the technology applied, in particular as far as compressed-air drying is concerned.