The only measuring tool in the world with digital readout for laser alignment of belt driven machine

The Easy-Laser® D160 detector unit can also be connected to our standard D279 display unit (used for shaft alignment) for full documentation.

The Easy-Laser® D160 detector unit can also be connected to our standard D279 display unit (used for shaft alignment) for full documentation.For futher information contact This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our website http://www.easy-laser.com

Artesis, a leading supplier of intelligent predictive maintenance solutions, has launched the MCM System on a Card (SoC), a product for the OEM sector, bringing a highly efficient and easy to use tool suite that allows the fast and complete integration of Artesis

Artesis, a leading supplier of intelligent predictive maintenance solutions, has launched the MCM System on a Card (SoC), a product for the OEM sector, bringing a highly efficient and easy to use tool suite that allows the fast and complete integration of Artesis

Andy Anthony, Operations Director with Monitran, discusses the importance of vibration sensor selection, placement and use for condition-based predictive maintenance.

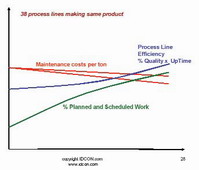

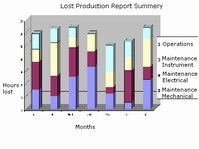

Andy Anthony, Operations Director with Monitran, discusses the importance of vibration sensor selection, placement and use for condition-based predictive maintenance. To continue where we ended part I of this series of articles about lean maintenance, I like to give an example on the impact of reliability in a situation where you can not sell everything you manufacture as a result of increased reliability. The example also shows the importance of including the quality component of the reliability formula.

To continue where we ended part I of this series of articles about lean maintenance, I like to give an example on the impact of reliability in a situation where you can not sell everything you manufacture as a result of increased reliability. The example also shows the importance of including the quality component of the reliability formula.  An effective root cause analysis process can improve production reliability significantly. But, few organizations have a functioning root cause analysis process in place. This article will discuss common problems and some suggested solutions in order to improve root cause problem elimination.

An effective root cause analysis process can improve production reliability significantly. But, few organizations have a functioning root cause analysis process in place. This article will discuss common problems and some suggested solutions in order to improve root cause problem elimination. The water industry is increasingly turning to predictive maintenance as it addresses the challenge of improving asset performance. Artesis has successfully combined advanced technology with a cost-effective implementation to meet their current and future needs.

The water industry is increasingly turning to predictive maintenance as it addresses the challenge of improving asset performance. Artesis has successfully combined advanced technology with a cost-effective implementation to meet their current and future needs. The Acoustic Emission (AE) technique is based on the detection of the high frequency component of naturally occurring stress waves (or structure borne elastic waves). There was a time when AE was regarded only as a means of monitoring defect growth in stressed materials and structures. Despite numerous instances of its successful application to machinery condition monitoring since the 1960

The Acoustic Emission (AE) technique is based on the detection of the high frequency component of naturally occurring stress waves (or structure borne elastic waves). There was a time when AE was regarded only as a means of monitoring defect growth in stressed materials and structures. Despite numerous instances of its successful application to machinery condition monitoring since the 1960  ~ Success due to customer focused implementation ~ Leicester based Cressall Resistors has put in a place a lean programme, managed by manufacturing director Cy Wilkinson, that has helped increase turnover by 100 per cent in 18 months. It has also contributed to the successful integration of a business, valued at over a million pounds, into the company's Leicester facility. The resultant plant layout uses less floor space than the original did before the new company was integrated.

~ Success due to customer focused implementation ~ Leicester based Cressall Resistors has put in a place a lean programme, managed by manufacturing director Cy Wilkinson, that has helped increase turnover by 100 per cent in 18 months. It has also contributed to the successful integration of a business, valued at over a million pounds, into the company's Leicester facility. The resultant plant layout uses less floor space than the original did before the new company was integrated. Energy savings, especially in the current economic climate are high on the agenda of all industry sectors, so components which offer, amongst other features, a precise and economical performance, are likely to be the preferred choice. Deltaflow flow meters recently introduced by FLOWLINE, meet these requirements for measuring media in gas, steam and liquid applications.

Energy savings, especially in the current economic climate are high on the agenda of all industry sectors, so components which offer, amongst other features, a precise and economical performance, are likely to be the preferred choice. Deltaflow flow meters recently introduced by FLOWLINE, meet these requirements for measuring media in gas, steam and liquid applications.