Based in North London with excellent access to the UK motorway network, FUCHS LUBRITECH UK provides the whole range of FUCHS LUBRITECH speciality products. In addition the plant has manufacturing and product support facilities for a specific range of specialised fluids and greases:

Based in North London with excellent access to the UK motorway network, FUCHS LUBRITECH UK provides the whole range of FUCHS LUBRITECH speciality products. In addition the plant has manufacturing and product support facilities for a specific range of specialised fluids and greases: • Milling and blending facilities for water, solvent and oil based solid lubricant dispersions and coatings. • High temperature greases and assembly pastes with solid lubricants and mineral oil and synthetic fluid components.

• Blending facilities for specialised fluid lubricants such as chain and rope oils. • Food grade manufacturing facility for NSF H1 approved oils and greases. • Clean manufacturing area for PFPE and PTFE lubricants and greases

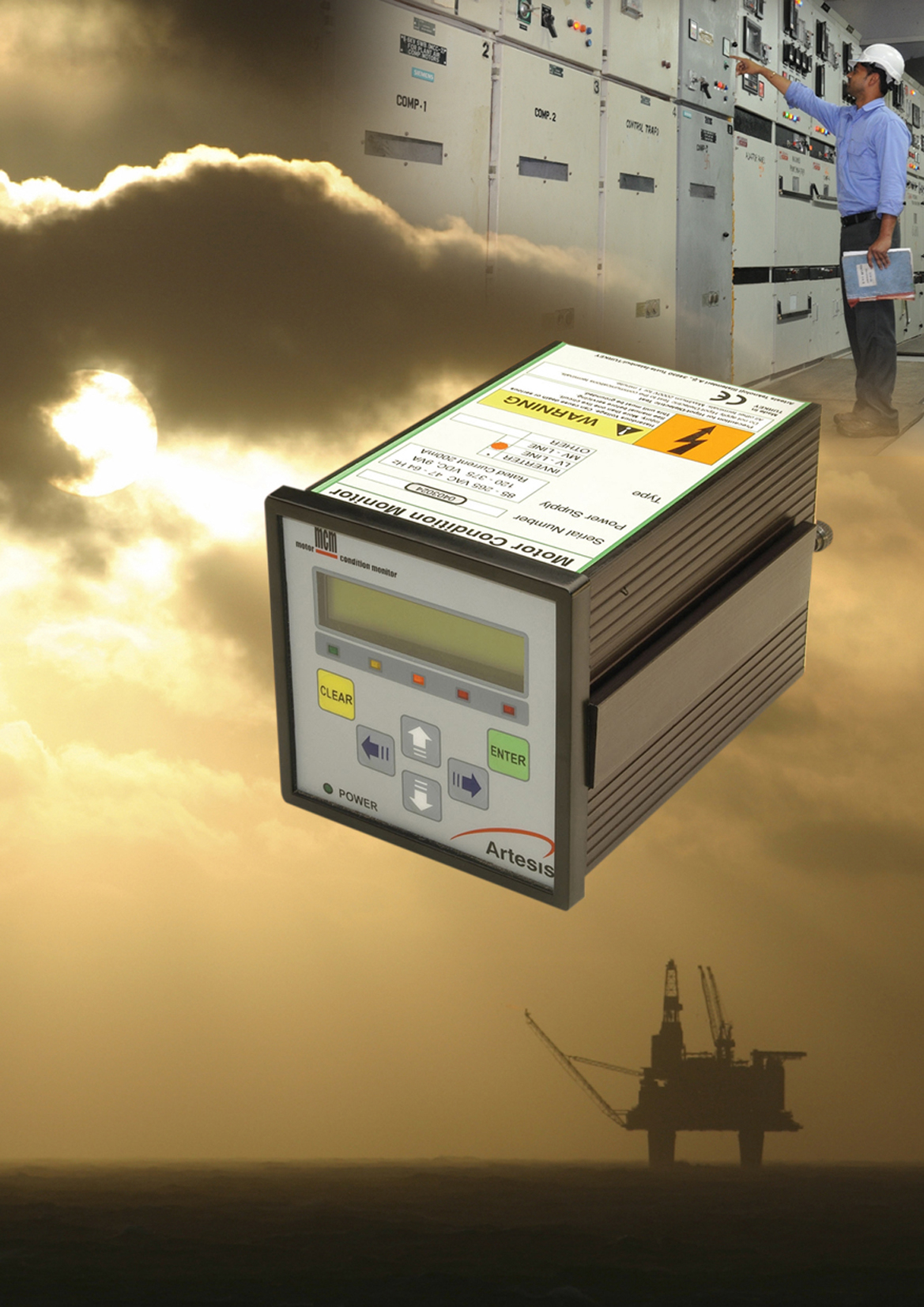

Artesis, a leading supplier of intelligent predictive maintenance solutions, is pushing the boundaries of machine monitoring technology with its next generation solution. Delivering a range of powerful new functionality the Artesis MCM (Motor Condition Monitor) system now includes wireless technology for deployment in remote and inaccessible locations; fully automated condition assessment reports for even faster diagnostics; and the ability for engineers to easily and quickly customise the application for wider enterprise use.

Artesis, a leading supplier of intelligent predictive maintenance solutions, is pushing the boundaries of machine monitoring technology with its next generation solution. Delivering a range of powerful new functionality the Artesis MCM (Motor Condition Monitor) system now includes wireless technology for deployment in remote and inaccessible locations; fully automated condition assessment reports for even faster diagnostics; and the ability for engineers to easily and quickly customise the application for wider enterprise use. As someone involved in the maintenance of a company’s assets, which may include plant machinery, vehicles, long term hire equipment, stock and spares; you will be aware of the bewildering amount of guidance on the subject. You may well be new to the subject having just been delegated to look at your company’s asset portfolio, or given this task in addition to other operations work.

As someone involved in the maintenance of a company’s assets, which may include plant machinery, vehicles, long term hire equipment, stock and spares; you will be aware of the bewildering amount of guidance on the subject. You may well be new to the subject having just been delegated to look at your company’s asset portfolio, or given this task in addition to other operations work. Until now, absolutely oil-free compressed air for sensitive applications could only be produced using relatively costly, often interconnected compressor- and filter-based technology.

Until now, absolutely oil-free compressed air for sensitive applications could only be produced using relatively costly, often interconnected compressor- and filter-based technology.  Testo, one of the leading worldwide suppliers of humidity measurement technology, now offers a humidity transmitter for hazradous areas. The new Testo 6682 humidity transmitter for Ex applications meets the most stringent requirements for process monitoring in industries including pharmaceutical, chemical and process technology.

Testo, one of the leading worldwide suppliers of humidity measurement technology, now offers a humidity transmitter for hazradous areas. The new Testo 6682 humidity transmitter for Ex applications meets the most stringent requirements for process monitoring in industries including pharmaceutical, chemical and process technology. The ATP Compact 4-in-1 Multi-Function Environment Meter is proving a popular addition to ATP Instrumentation

The ATP Compact 4-in-1 Multi-Function Environment Meter is proving a popular addition to ATP Instrumentation  Four new courses have been added to this year

Four new courses have been added to this year