Why Monitor?

Why Monitor? Michell Instruments has re-launched its Coreci and Rense ranges of relative humidity instruments and sensors under the Michell Instruments brand. A new catalogue containing the complete range, as well as dew point transmitters and calibration instruments, is now available.

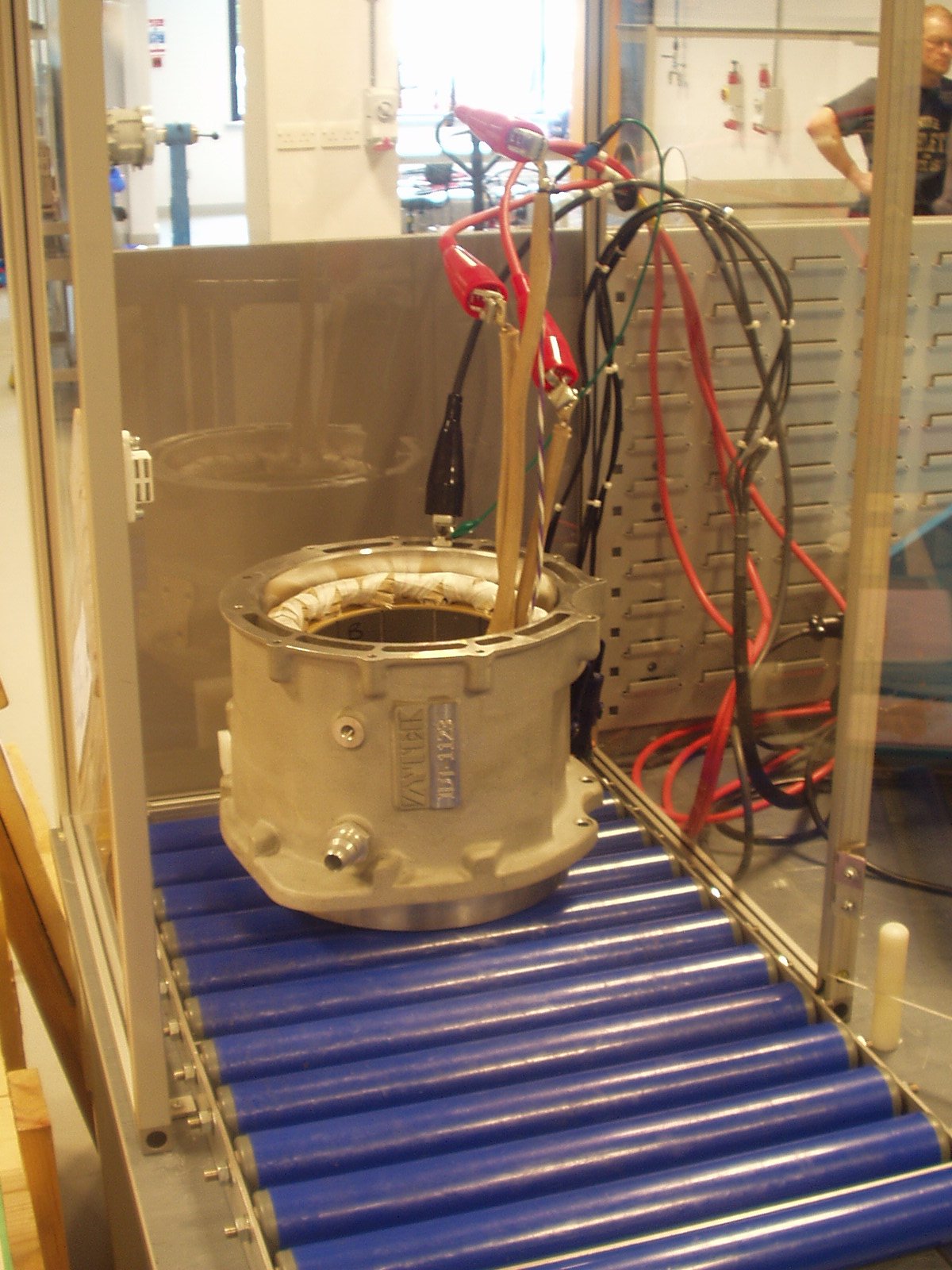

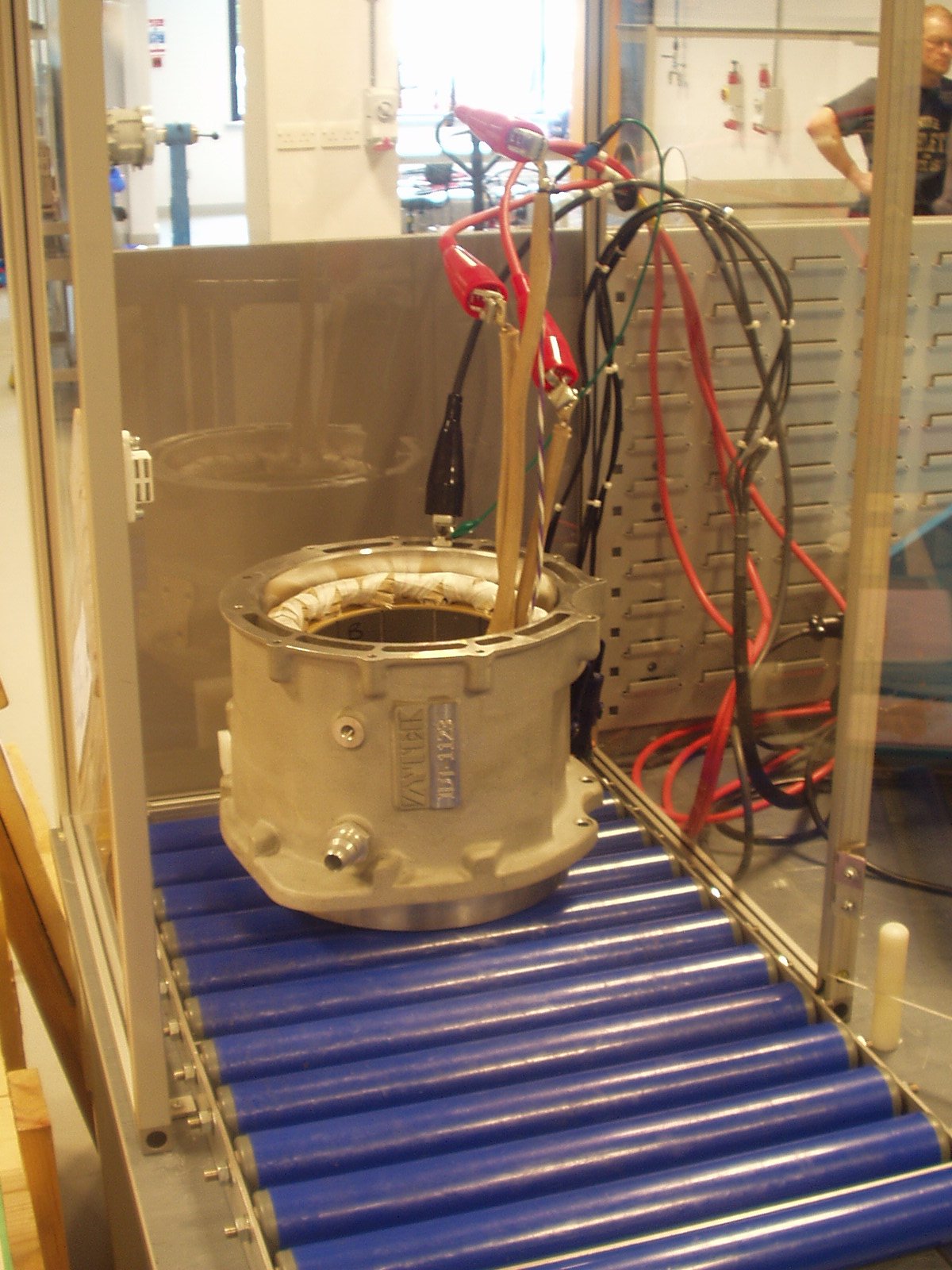

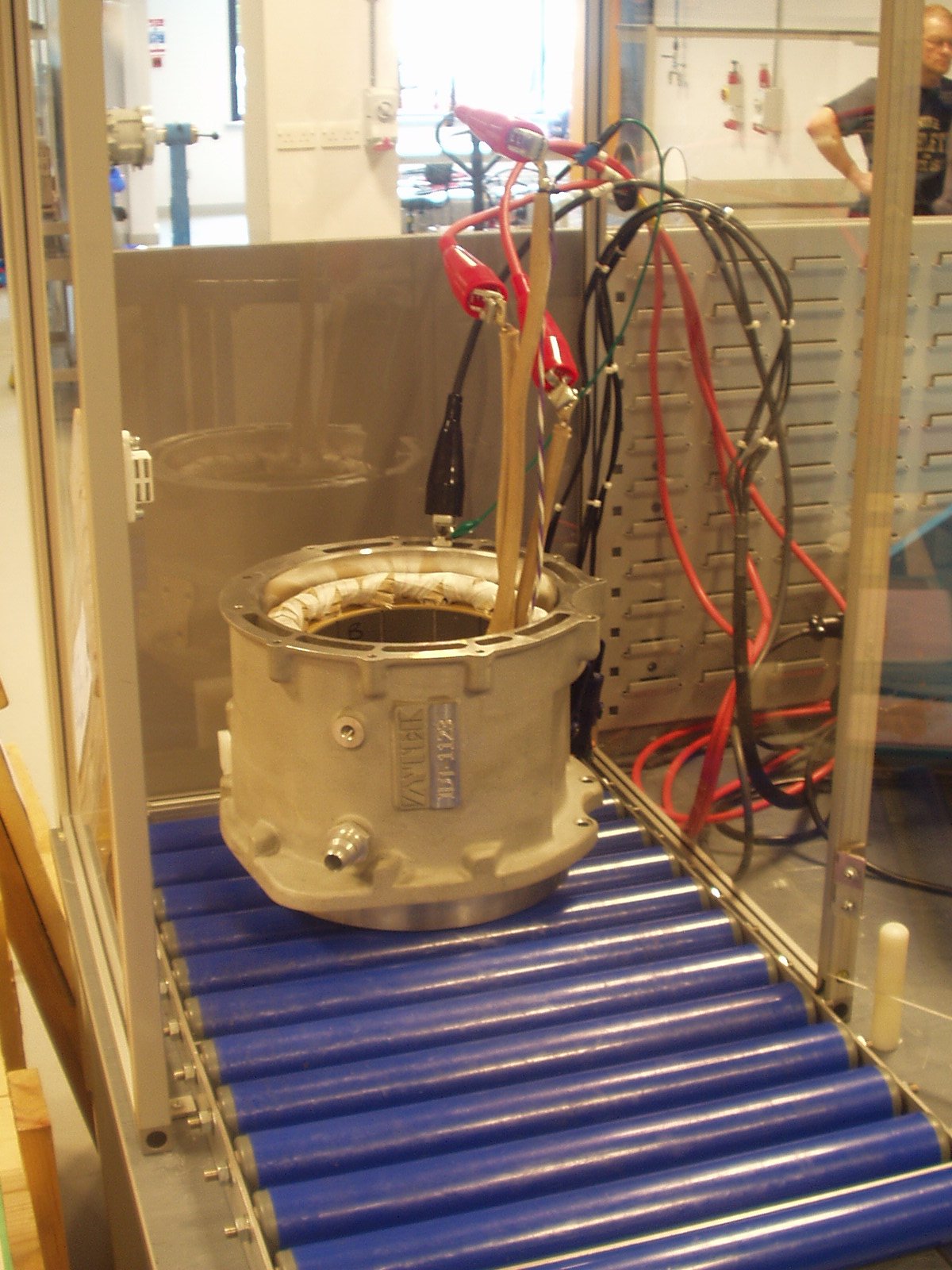

Michell Instruments has re-launched its Coreci and Rense ranges of relative humidity instruments and sensors under the Michell Instruments brand. A new catalogue containing the complete range, as well as dew point transmitters and calibration instruments, is now available. It was in 1816 that the Revd. Robert Stirling propounded the idea of a heat engine which he termed an ‘Economiser’ now universally known as a ‘Stirling Engine’. The operational concept is that it acted as a heat exchanger, retaining heat from the hot portion of the engine as air passed to the cold side, and released heat to the cooled air as it returned to the hot side and in the process converting energy to mechanical work, with near perfect efficiency.

It was in 1816 that the Revd. Robert Stirling propounded the idea of a heat engine which he termed an ‘Economiser’ now universally known as a ‘Stirling Engine’. The operational concept is that it acted as a heat exchanger, retaining heat from the hot portion of the engine as air passed to the cold side, and released heat to the cooled air as it returned to the hot side and in the process converting energy to mechanical work, with near perfect efficiency. Bombardier Transportation has its global headquarters in Berlin, Germany with a presence in over 60 countries. It has an installed base of over 100,000 vehicles worldwide.

Bombardier Transportation has its global headquarters in Berlin, Germany with a presence in over 60 countries. It has an installed base of over 100,000 vehicles worldwide.  More and more often, industrial applications expect mobility and flexibility from compressed-air processing. For example for the employment at different sites or outdoors. A solution to that is the installation of complete compressed-air stations in transportable sea containers. These mobile performance centres make special demands on the technology applied, in particular as far as compressed-air drying is concerned.

More and more often, industrial applications expect mobility and flexibility from compressed-air processing. For example for the employment at different sites or outdoors. A solution to that is the installation of complete compressed-air stations in transportable sea containers. These mobile performance centres make special demands on the technology applied, in particular as far as compressed-air drying is concerned.

In practice noise date are not always consistent. Noise at machines can stem from unknown sources. It is important to know what noise levels can be found in the system and what causes them. PRUFTECHNIK Condition Monitoring performs acceptance measurements of noise emissions and compares the results with the latest standards. If necessary, suitable measures for noise reduction are identified and recommended. Measurements are made with the data analyzer VIBXPERT and evaluated with DBSpectra and the software OMNITREND. Dominant noise sources can be identified using third octave or narrow band spectra.

“Achievable noise reductions, e.g. in gear drives, can be up to 5 dB: through measures on housings, up to 7 dB: through measures on rotors, toothing and housings and up to 10 dB: through secondary noise shields or enclosures” says Dr. Edwin Becker, Manager Service and Diagnostic Center.

VIBROTIP is an extremely rugged and easy-to-use

hand-held data collector for five key indicators of machine condition. All sensors are built in, with no cumbersome cables or fragile plugs.

VIBCODE (optional) can be used to eliminate mixups of measurement location and type, and

VIBCODE (optional) can be used to eliminate mixups of measurement location and type, and  OMNITREND PC software automatically archives trend data, issues warnings and alarms and programs VIBROTIP with all desired measurements.

OMNITREND PC software automatically archives trend data, issues warnings and alarms and programs VIBROTIP with all desired measurements.

The DC 1800 EX is suitable for general cleaning and source extraction. The DC 1800 is small and lightweight, therefore suitable for those that need a highly portable machine that still is powerful enough for source extraction. With its low weight it is easy to carry onto the job site and it can be easily stored or rolled under a workbench.

The DC 1800 EX is suitable for general cleaning and source extraction. The DC 1800 is small and lightweight, therefore suitable for those that need a highly portable machine that still is powerful enough for source extraction. With its low weight it is easy to carry onto the job site and it can be easily stored or rolled under a workbench.