To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group.

To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group. As the world leader in glass bead impact technology, Potters is continually developing and refining its manufacturing procedures to ensure consistently high quality glass spheres, which are tested to conform to every market specification.

To ensure customers can immediately comply with current regulations, Airchannel, the UK’s leading independent compressed air specialist, is providing an integrated Written Scheme of Examination (WSE) as part of its complete service.

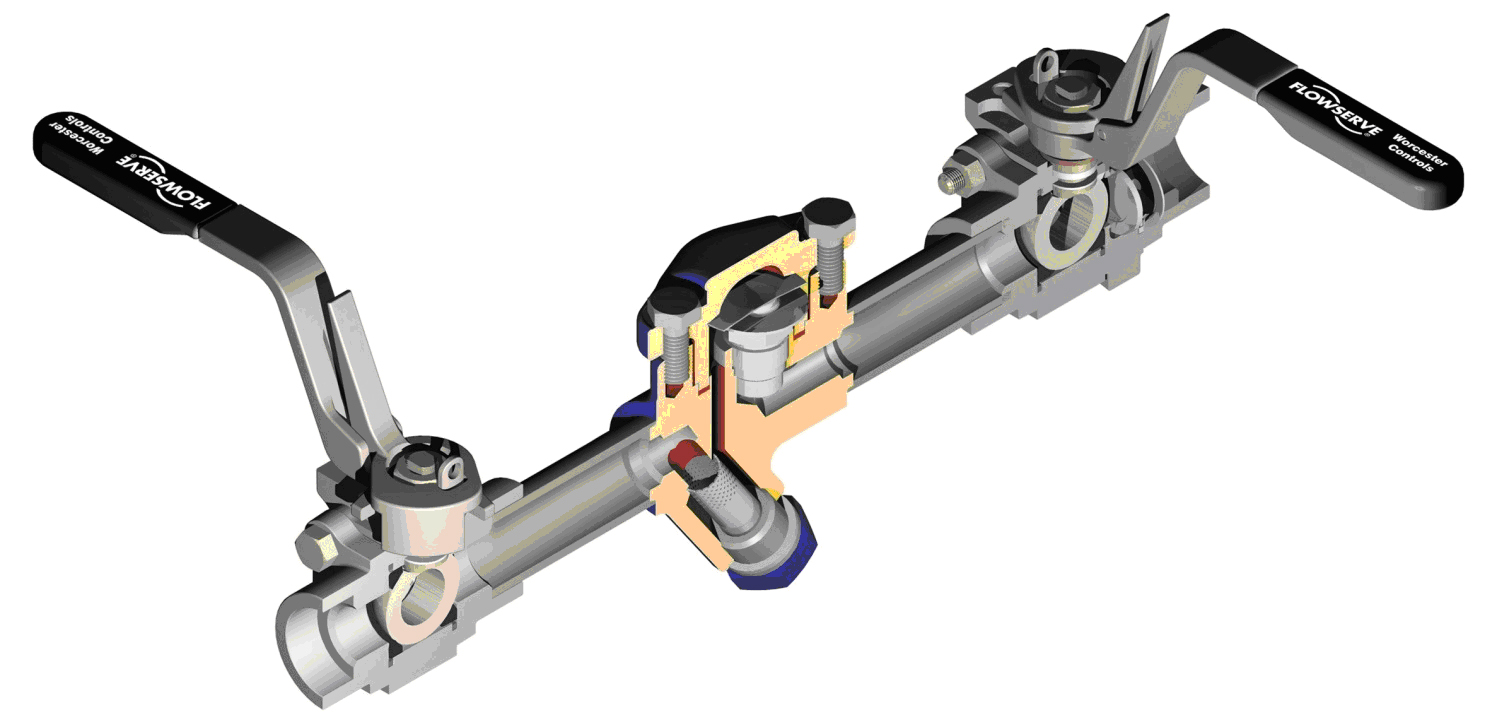

To ensure customers can immediately comply with current regulations, Airchannel, the UK’s leading independent compressed air specialist, is providing an integrated Written Scheme of Examination (WSE) as part of its complete service. Valveforce launched a new range of compact steam trap set stations to provide easy to maintain cost effective solutions to help Maintenance Engineers work quicker and more efficiently on their steam trap sets.

Valveforce launched a new range of compact steam trap set stations to provide easy to maintain cost effective solutions to help Maintenance Engineers work quicker and more efficiently on their steam trap sets.

We introduce our 'unique' Explosion Proof Mobile Dust Extraction unit which is 'LEGALLY' certified ATEX Zone 21 and Zone 1 (Gas/Dust). Constructed in Stainless Steel (other materials available), it is the only Mobile unit available with this certification. Ideal for Pharmaceutical/Medical, Food industries as it has full HEPA filtration and is cleanroom compatible.

We introduce our 'unique' Explosion Proof Mobile Dust Extraction unit which is 'LEGALLY' certified ATEX Zone 21 and Zone 1 (Gas/Dust). Constructed in Stainless Steel (other materials available), it is the only Mobile unit available with this certification. Ideal for Pharmaceutical/Medical, Food industries as it has full HEPA filtration and is cleanroom compatible. ARC Technologies, is the authorised distributor for ‘Tiger-Vac’ ATEX rated Industrial Vacuum Cleaner Systems for wet or dry recovery. ’ LEGALLY’ Certified for hazardous locations: Fuel, metal dust, pharmaceutical powder, shooting ranges, flour mills, carbon black, nuclear, etc.

ARC Technologies, is the authorised distributor for ‘Tiger-Vac’ ATEX rated Industrial Vacuum Cleaner Systems for wet or dry recovery. ’ LEGALLY’ Certified for hazardous locations: Fuel, metal dust, pharmaceutical powder, shooting ranges, flour mills, carbon black, nuclear, etc. BEKO Technologies is further extending its product range by launching their first e-learning course - “The Basics of Compressed Air Technology”. This innovative course is now available to all customers and partners, giving them the chance to share and benefit from BEKO’s vast experience in compressed air.

BEKO Technologies is further extending its product range by launching their first e-learning course - “The Basics of Compressed Air Technology”. This innovative course is now available to all customers and partners, giving them the chance to share and benefit from BEKO’s vast experience in compressed air.