PMJ International, the one stop shop for all your compressed air needs have two special offers for September for EMS readers. Any timed automatic drain ¼” ⅜” ½” port size in any voltage 24v 110v 240V only £23.50 each! (Please quote E09 when ordering). All orders over £300.00 will be delivered CARRIAGE FREE.

PMJ International, the one stop shop for all your compressed air needs have two special offers for September for EMS readers. Any timed automatic drain ¼” ⅜” ½” port size in any voltage 24v 110v 240V only £23.50 each! (Please quote E09 when ordering). All orders over £300.00 will be delivered CARRIAGE FREE.PMJ International has over 30 years experience in supplying a comprehensive and ever expanding range of genuine and alternative compressor and vacuum parts for most of the worlds leading manufacturers.

Spares management is a complex issue for manufacturers, almost regardless of the sector in which they are operating. Rapid access to spares is of course vital to maintaining continuity of production and avoiding costly downtime.

Spares management is a complex issue for manufacturers, almost regardless of the sector in which they are operating. Rapid access to spares is of course vital to maintaining continuity of production and avoiding costly downtime. Samsung Techwin has introduced the STC-14, a fixed thermal imaging camera with a built-in 14mm lens and 4x digital zoom suitable for effective detection over large areas.

Samsung Techwin has introduced the STC-14, a fixed thermal imaging camera with a built-in 14mm lens and 4x digital zoom suitable for effective detection over large areas. Send for your free pocket guide to TPM and see how you can greatly improve the condition and performance of your company assets and operational processes using shop floor based teams. The guide has been produced by Roy Davis, probably the most experienced TPM implementer in the UK.

Send for your free pocket guide to TPM and see how you can greatly improve the condition and performance of your company assets and operational processes using shop floor based teams. The guide has been produced by Roy Davis, probably the most experienced TPM implementer in the UK.  Spidex Software has announced that Global Renewables, an innovative resource recovery specialist, has selected Spidex’s Mainsaver CMMS solution to manage engineering maintenance at its two newly-built state-of -the-art waste treatment facilities in Lancashire.

Spidex Software has announced that Global Renewables, an innovative resource recovery specialist, has selected Spidex’s Mainsaver CMMS solution to manage engineering maintenance at its two newly-built state-of -the-art waste treatment facilities in Lancashire. Profitability is everything in a competitive environment. BEKO Technologies, the market leaders in compressed air technology, boast a comprehensive program of systems designed to save energy and improve efficiency in the application of compressed air.

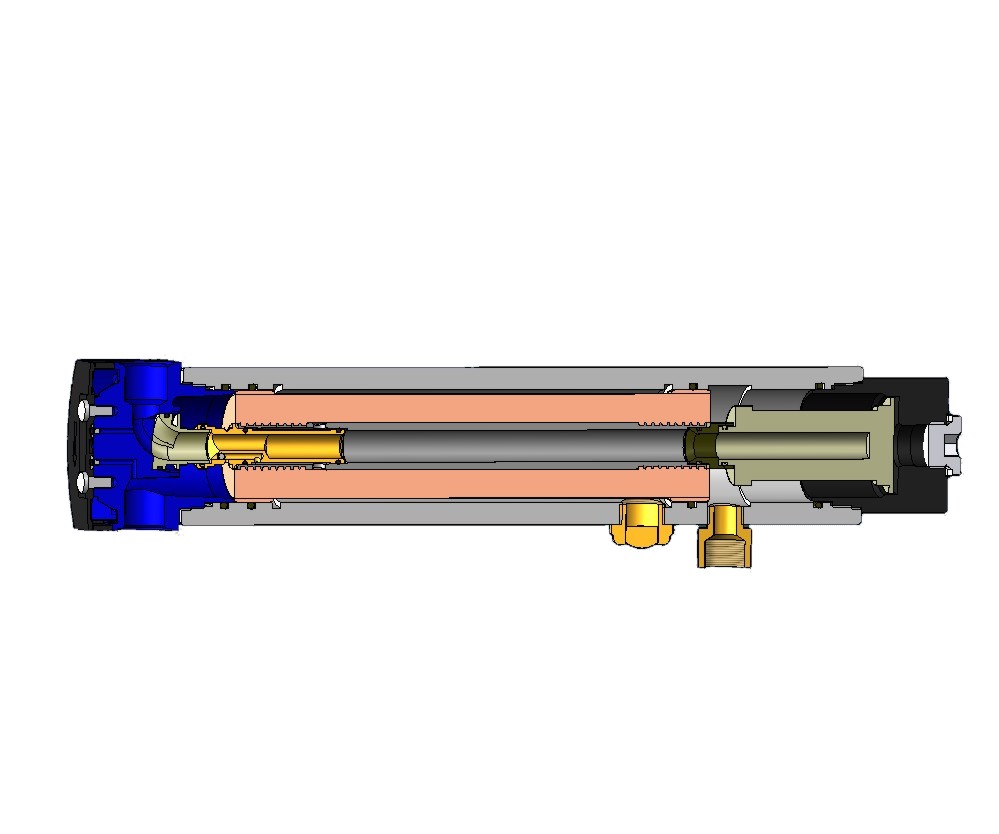

Profitability is everything in a competitive environment. BEKO Technologies, the market leaders in compressed air technology, boast a comprehensive program of systems designed to save energy and improve efficiency in the application of compressed air. The DRYPOINT® M PLUS membrane dryers with an integrated nanofilter made by BEKO TECHNOLOGIES, Neuss, Germany, have proven themselves particularly useful when employed downstream of compressors (in satu-rated compressed air which is warmer than the ambient air).

The DRYPOINT® M PLUS membrane dryers with an integrated nanofilter made by BEKO TECHNOLOGIES, Neuss, Germany, have proven themselves particularly useful when employed downstream of compressors (in satu-rated compressed air which is warmer than the ambient air).