Hazardous Environments

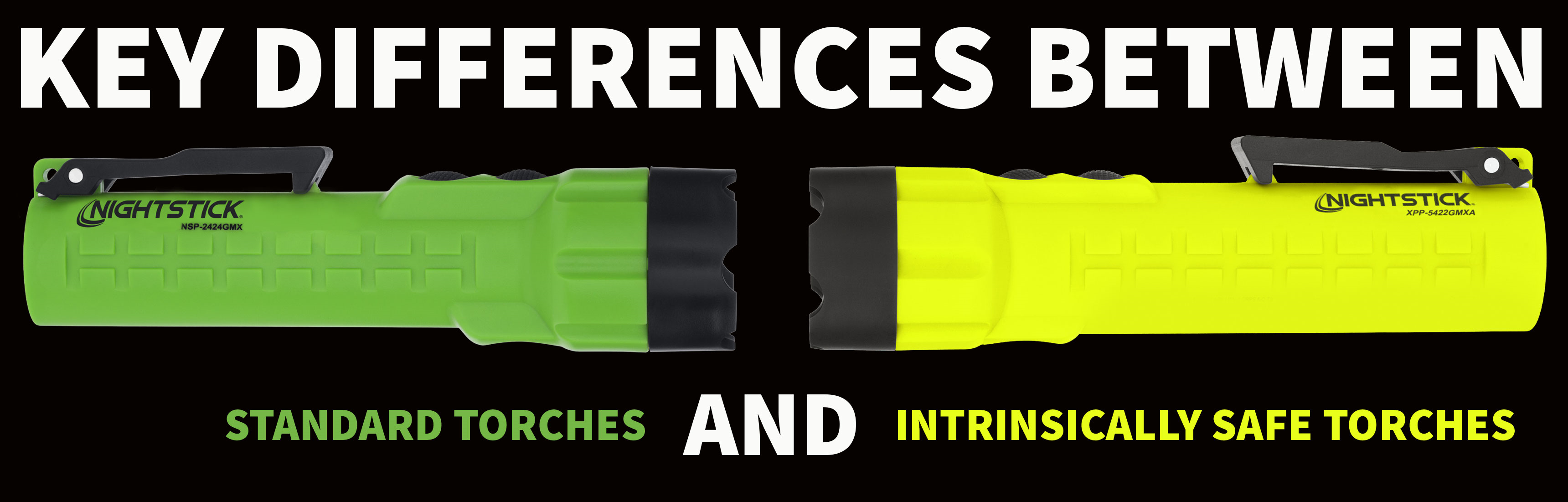

Intrinsically safe torches are rated and certified for use in explosive atmospheres and hazardous environments where even the slightest spark can result in an explosion. Standard torches have no consideration for limiting sparks and are extremely dangerous to use in a potentially explosive atmosphere.

Body Materials

Standard torches are generally made from a low-cost ABS (acrylonitrile butadiene styrene) plastic. In contrast, intrinsically safe torches are made from very costly materials like Polycarbonate/ABS Alloy with permanently static dissipative UV stabilized additives. These additives dissipate static electricity that can build up on the surface of the light to prevent sparks and cost twice as much as standard ABS plastic. Additionally, IS torches must posse unique design features to contain battery leakage and venting for gases produced in the event of a battery malfunction.

Lens Materials

Standard torches are traditionally made out of transparent polycarbonate plastic. Intrinsically safe torches also use transparent polycarbonate but require an additional (and costly) special coating that dissipates static electricity.

Circuitry

Intrinsically safe torches require professional electrical engineers to design and develop circuits specifically created to meet the requirements necessary to pass the strict certification levels for an intrinsically safe rating. This is achieved by designing circuits that prevent or limit spark energy through the use of fuses, redundant circuit paths, diodes, and other components. Standard torches have an on/off switch.

Special Fasteners

Because intrinsically safe torches are rated for use in hazardous and explosive environments, they must remain sealed in and around those areas. This requires that torches not be opened to change batteries even by accident while in a hazardous environment, and thus, a special retention screw or "special fastener" is used to keep the light from being opened. A standard torch is easily opened, usually by unscrewing one end of the light.

Because of the knowledge and expense required to engineer IS-certified products, a limited number of companies can achieve this. Nightstick is a global manufacturer of over 50+ Intrinsically Safe professional, portable LED lighting products. Locate a dealer near you at www.nightstick.com

This article can also be found in the issue below.

ATEX protection is all centred around preventing an explosion from happening when there is a presence of combustible dust or flammable gas, this means considering all potential ignition sources. When looking at sources, most people will look for sparks and flames as an obvious risk, but the gas or dust properties themselves are an important aspect to protect against.

ATEX protection is all centred around preventing an explosion from happening when there is a presence of combustible dust or flammable gas, this means considering all potential ignition sources. When looking at sources, most people will look for sparks and flames as an obvious risk, but the gas or dust properties themselves are an important aspect to protect against.