There is no safe level of vibration exposure. Using powered hand tools over time will harm health and severely limit quality of life. Vibration exposure through the continual use of vibratory tools kills the nerve cells and blood vessels in fingers and hands, this irreversible damage results in consistent pain and prevents the sufferer from undertaking even the simplest of manual tasks.

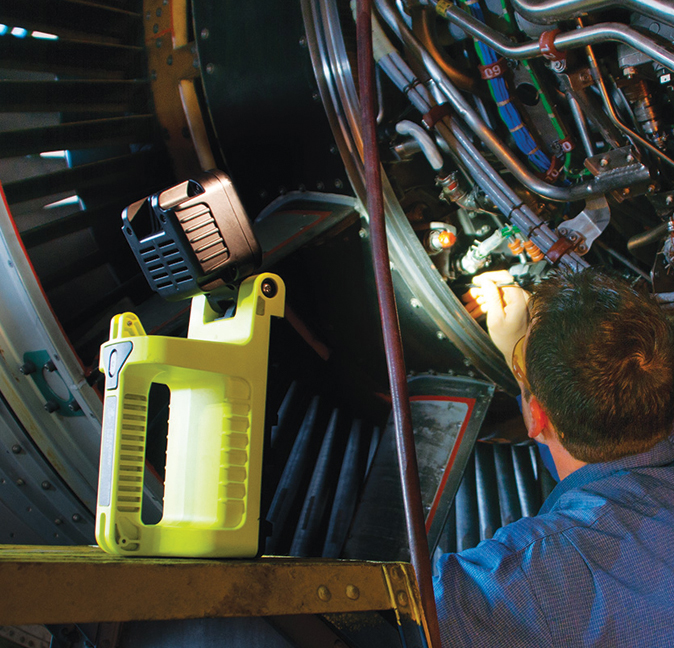

Until now, those operatives working in potentially explosive atmospheres have been left without a suitable and sufficient solution to monitor and reduce Hand Arm Vibration risk.

Market leading HAV risk management specialists HAVi are the world’s only provider of an integrated solution to managing HAV risk in potentially explosive atmospheres. The solution is certified to ATEX, UKEX and IECEx standards for hardware up to and including Zone 0.

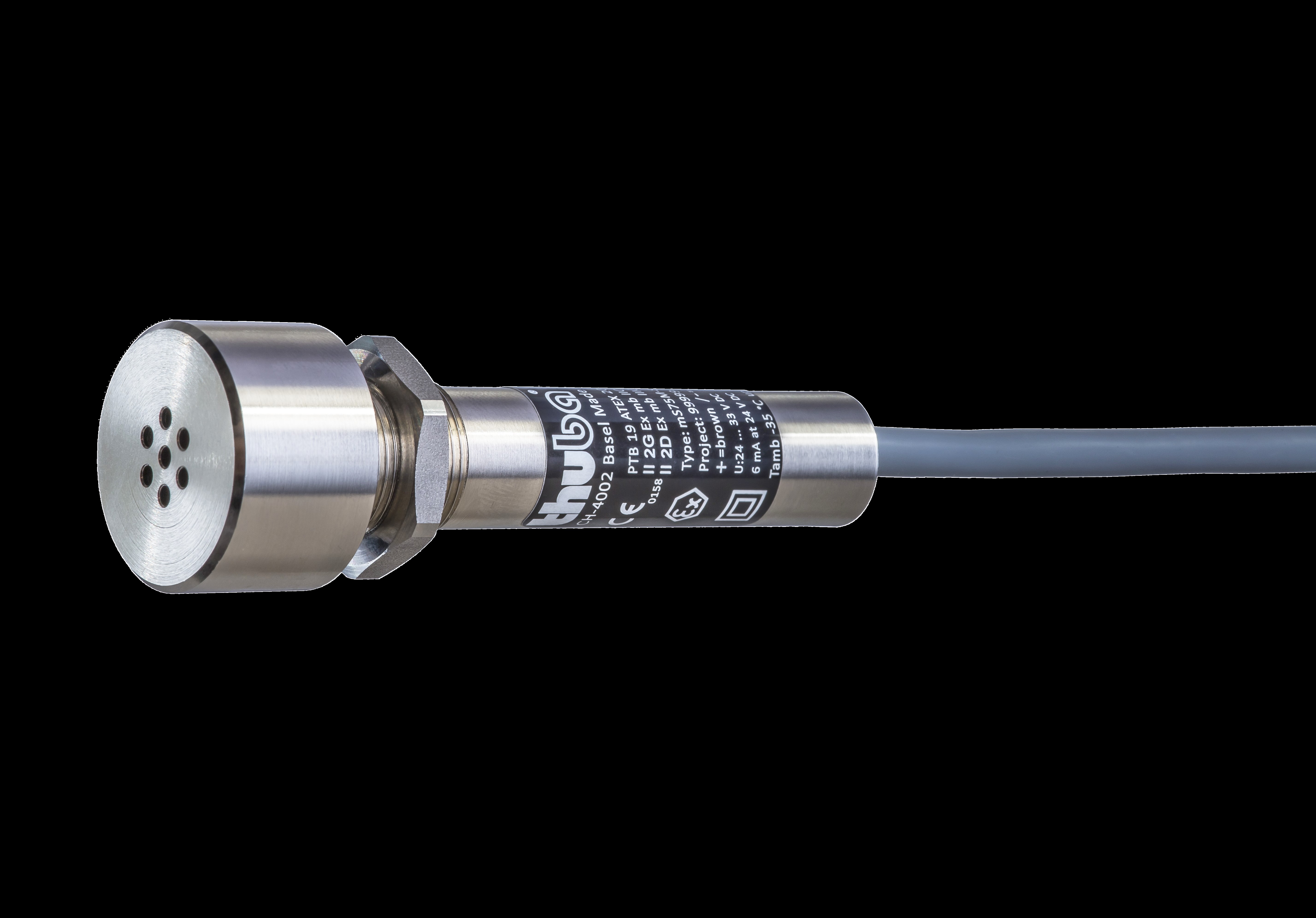

Accurate and trusted explosion-proof vibration monitoring

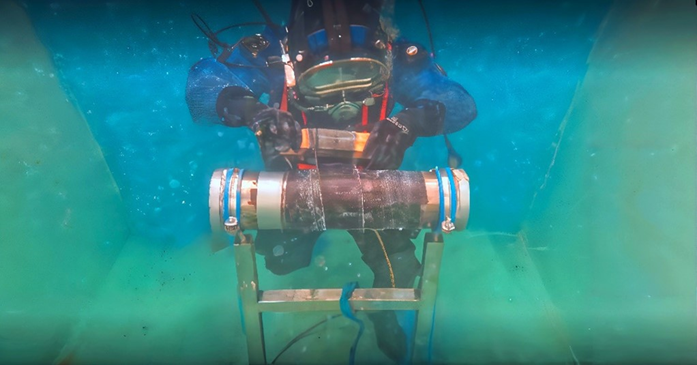

HAVi’s robust solution has been trusted to manage risk in the harshest of environments since 2008. With numerous successful implementations in Construction, Rail, Automative, Facilities Management, Utilities and Oil & Gas infrastructure, you can be certain of a credible partner.

The core solution underwent rigorous design, testing and evaluation which resulted in the launch of a range of Trigger Timers and Wearables under the “HAVi ATEX” banner. The range utilises components and casings specifically selected to meet the requirements of the Intrinsically Safe protection concept.

The new range integrates seamlessly into the HAVi ecosystem meaning you can minimise your investment and only specify Ex rated equipment for areas that require it.

Compliance assured

The HAVi solution is designed to meet HSE and BS EN / ISO requirements in full. In another market first, HAVi will also document this compliance following implementation.

Collecting data does not equal compliance. Powered by ActivIQ, HAVi’s innovations in the field of insight management and analytics, help you make better decisions, faster to lower risk.

Added to that, experiential E-learning and in person courses designed to train and inform the operators about HAV risk and help ensure that they fully engage with their risk and take actions to help reduce personal exposure.

Our experienced team can provide full turn-key or modular solutions ranging from Site Audits, the creation and evaluation of Risk Assessments, tool Vibration Magnitude measurements and working with you we can implement bespoke culture change projects to reinforce your key safety messages.

Continuous Improvement

The combination of HAVi’s intrinsically safe EX certified hardware and peerless HAV management solutions equip businesses operating in hazardous and explosive conditions with the safest and most accurate data and the actionable insights that protect the hand health of the tool operators by effectively managing and reducing vibration exposure.

HAVi’s Kate Louise Cole said: “For too long, those operating in Ex environments have been excluded from accurate assessments of Vibration Exposure. It is our privilege to be able to address this with our world first solution. Coupled with this, our decades of experience will help you remain compliant and most importantly protect your people, wherever they work”

For more information on HAVI visit thehavi.com or to speak to the team call 0115 932 7002

Ends

For more information please contact Gemma Sharpe at Tactic Communications | This email address is being protected from spambots. You need JavaScript enabled to view it. / 07807 152835.