As the global demand for lithium continues to surge, driven by the rise of electric vehicles and renewable energy technologies, the maintenance challenges faced by lithium mining operations have become increasingly critical. Belzona, a leader in industrial protective coatings, headquartered in Miami Lakes, Florida, is addressing these challenges head-on with its innovative polymeric solutions. Designed to combat corrosion, abrasion, and chemical damage, Belzona's coatings are playing a pivotal role in extending the life of critical mining equipment, supporting the industry's efforts to meet growing demands while promoting sustainability.

Polymeric Solutions for Maintenance Problems for Lithium Mining

Batteries are a highly sought-after product due to the ever-growing need for green electric appliances and devices. Phones, solar panels, and electric vehicles (EVs) all need batteries to operate, and this has led to an increase in the need for materials used to manufacture batteries. Lithium is one material whose need has increased tenfold. Some of the already large lithium mines in South America, Asia, and Australia have had to expand to meet the high demands of energy and tech companies.

Lithium-ion batteries play an important role in reducing climate change. EVs reduce the need for gasoline and diesel fuel. In addition, energy companies use lithium-ion batteries to store electricity generated from wind and solar farms to mitigate the use of energy generated from coal and natural gas. However, lithium mining does have its drawbacks. It is responsible for over 1.4 million US tons (1.3 million metric tons) of carbon annually. For every one US ton (0.9 metric ton) of mined lithium, 16.5 US tons (15 metric tons) of CO2 are released into the air (earth.org).

Figure 1 An example of a lithium-ion battery for mobile devices

The Environmental Impact of Lithium Mining

Additionally, the lithium mining process is very intense in the surrounding environment. Part of the process involves extracting lithium from saltwater reserves. It risks polluting the local water sources, threatening humans and local animal and plant biodiversity. The batteries themselves can also be harmful to the environment. They can leech damaging chemicals and other byproducts into the environment when they are discarded. It can cause fires, water pollution, air pollution, and health problems. Despite the negatives, the current process is the most cost-effective way to obtain lithium; however, other materials are being researched to manufacture greener batteries (earth.org).

How is Lithium Mined?

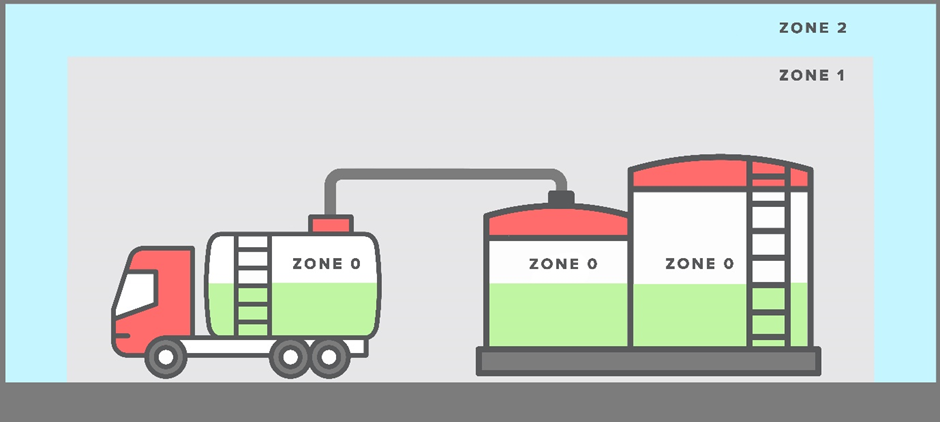

The current lithium mining process involves drilling underground to access mineral-rich brine found under salt flats. Then, the brine is pumped into large evaporation pools on the Earth’s surface. The Sun slowly evaporates the brine pools over months or years leaving behind minerals like potassium, sodium, and lithium. The lithium is then extracted in different ways but usually involves a chemical process by which reagents are incorporated to form a saleable compound of lithium at a processing facility that can be transported to customers.

There are other less common lithium mining processes such as extracting directly from mineral ore. During this process, the mineral is extracted, heated, and pulverized. Then, it is combined with reagents to create a slurry that is heated, filtered, and concentrated via evaporation to produce a saleable lithium form (Samco.com).

Figure 2 Evaporation pool used during lithium mining

Solving Corrosion During Lithium Mining

Corrosion is a common maintenance problem found in lithium mines due to the presence of brine, a water-based solution high in minerals, especially salt. Brine accelerates corrosion because of an increase in dissolved ions, which allows electrons to move freely between the brine and metal substrate causing rust. A metal object does not need to be submerged for corrosion to occur as increased moisture in the air and salt spray can also rust metal substrates (sciencing.com).

A manufactured paint or coating can stop corrosion because it can prevent the ions from interacting with the metal substrate. Belzona polymeric coatings are applied on various substrates from aluminum, steel, iron, and more to stop the materials from corroding.

During lithium mining, equipment, and assets often find themselves in the presence of brine or moisture. A pump is used to transport brine from the underground reservoir to the evaporation pools. The pump can suffer from rust and corrosion due to the mineral-rich water; however, a Belzona 1000 Series coating can prevent the piece from corroding. The coatings also repair the piece as specific products such as metal repair epoxy paste, Belzona 1111 (Super Metal), and corroded metal repair material, Belzona 1121 (Super XL-Metal) can help rebuild metal loss. Rebuilding can reduce the need for a new part especially the downtime from waiting for a new part.

Figure 3 Pump repaired with Belzona 1111 (Super Metal) suffering from corrosion due to saltwater medium

Other equipment in contact with water or moisture such as froth flotation cells, pressure leaching tanks, filters, centrifuges, evaporators, mixers-settlers/ extraction columns, and electrolysis equipment can all potentially be coated with a Belzona 1000 Series to protect them from further corrosion and replacement.

Solving Abrasion and Physical Impact During Lithium Mining

The equipment may become physically damaged also as they deal with rough materials like mineral particles of varying sizes. The particles can slowly deteriorate the surface of metal or rubber equipment. Pumps are an example of equipment that is physically damaged by solid particles, but conveyor belts and loaders are also a great example of two pieces of equipment made of different materials that suffer from similar damage. Both assets carry and transport lithium and other solid materials. During this phase of the lithium mining process, the assets endure harsh wear and tear, damaging their integrity. Holes will appear in conveyor belts and metal loss will slowly abrade the surface of the loader.

Belzona can provide a quick return-to-service with the Belzona 2000 Series, a product line engineered to repair flexible components. Tears and abrasions on conveyor belts are repaired without the need for hot work with Belzona’s elastomer products which provide a much-needed increase in durability, elasticity, and tear resistance.

Figure 4 Conveyor belt back in operation after repaired with Belzona 2311

Additionally, loaders and other metal equipment such as filters, haul trucks, drills, crushers, and grinding mills can be coated with Belzona 1000 Series to rebuild metal substrates that have abraded. Belzona 1311 (Ceramic R-Metal) and other products in the range can rebuild the equipment’s surface while safeguarding it from further abrasion. The coating creates a sturdy barrier between the rough material and the substrate, and it is reinforced by the composition of the coating.

Chemical Resistant and High-Temperature Coatings for Lithium Mining

Reagents are an important part of lithium mining. Usually, these reagents are strong chemicals like sulfuric acid. Additionally, depending on the mining process, it can involve high-temperature reactions. Coatings in the Belzona 1000 Series and 4000 Series include products to protect assets during high-temperature operations or with chemicals. If there is a high concentration of sulfuric acid (98%) then Belzona 4311 or Belzona 4341 would be an appropriate choice. Lower concentrations can be resisted with other Belzona 4000 Series coatings; however, any coating performance is highly dependent on temperature.

Belzona 1511 (Super HT-Metal) or Belzona 1813 offer high-temperature resistance of up to 150 °C (302 °F) and 200 °C (392 °F) respectively. They have been formulated to protect metal surfaces from abrasive attack (Belzona 1813) and corrosive attack (Belzona 1511) at high temperatures and are resistant to a wide range of chemicals.

Figure 5 Chute coated with Belzona 1813 for high-temperature resistance

Belzona’s Importance to Greener Lithium Mining Practices

Lithium mining is integral to the production of batteries that power a variety of essential green technologies, from EVs to renewable energy storage systems. Despite its significant environmental footprint, including carbon emissions and potential water pollution, advancements in mining processes and material science are making strides toward mitigating these impacts. One of the critical challenges faced by the industry is the maintenance of equipment exposed to harsh conditions, such as corrosion, abrasion, and chemical attack.

Belzona's range of polymeric solutions offers robust protection and repair options for mining equipment. By preventing corrosion, repairing physical damage, and providing chemical and high-temperature resistance, these solutions not only extend the lifespan of critical assets but also enhance operational efficiency and safety. As the demand for lithium continues to rise, the application of innovative maintenance solutions like Belzona's will be crucial in supporting sustainable mining practices and the transition to a greener, more sustainable future.

Figure 6 Electric vehicle

www.belzona.com