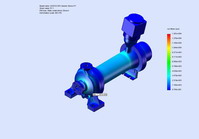

Hayward Tyler Group, a leading manufacturer of glandless motor/pumps for power generation, oil & gas, nuclear and subsea applications, is using the latest 3D modelling and finite element analysis (FEA) software to accurately predict overall stress distribution for complete motor pump assemblies, resulting in reduced engineering lead times for its customers.

Hayward Tyler Group, a leading manufacturer of glandless motor/pumps for power generation, oil & gas, nuclear and subsea applications, is using the latest 3D modelling and finite element analysis (FEA) software to accurately predict overall stress distribution for complete motor pump assemblies, resulting in reduced engineering lead times for its customers.Hayward Tyler Inc. (HTI) Engineering recently invested in COSMOSWorks Professional, a software package that includes a Pressure Vessel Design Study option, which is being used in combination with 3D solid modelling software from Solidworks.

The Acoustic Emission (AE) technique is based on the detection of the high frequency component of naturally occurring stress waves (or structure borne elastic waves). There was a time when AE was regarded only as a means of monitoring defect growth in stressed materials and structures. Despite numerous instances of its successful application to machinery condition monitoring since the 1960

The Acoustic Emission (AE) technique is based on the detection of the high frequency component of naturally occurring stress waves (or structure borne elastic waves). There was a time when AE was regarded only as a means of monitoring defect growth in stressed materials and structures. Despite numerous instances of its successful application to machinery condition monitoring since the 1960  By introducing change management and version control software for all industrial programmable devices in its Wakefield manufacturing plant, soft drinks giant Coca Cola Enterprises (CCE) has minimised production downtime, therefore avoiding costly delays and disrupting delivery schedules.

By introducing change management and version control software for all industrial programmable devices in its Wakefield manufacturing plant, soft drinks giant Coca Cola Enterprises (CCE) has minimised production downtime, therefore avoiding costly delays and disrupting delivery schedules. Major investment in new plant will practically double output at the Simpson

Major investment in new plant will practically double output at the Simpson  By monitoring the vibrations from critical components inside a hydraulic pump, fan, blower or compressor, companies can improve their plant efficiencies, eliminate production downtime and increase the operating life and reliability of plant equipment, says Ian Taylor of Corus Northern Engineering Services (CNES).Although the cost of a component inside a hydraulic pump, such as a rolling element bearing, rotor or fastener, is often very small compared to the total cost of the pump, the cost of production downtime and any consequential losses as a result of a component failure, are often significant.

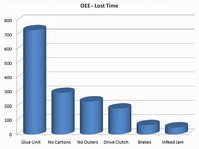

By monitoring the vibrations from critical components inside a hydraulic pump, fan, blower or compressor, companies can improve their plant efficiencies, eliminate production downtime and increase the operating life and reliability of plant equipment, says Ian Taylor of Corus Northern Engineering Services (CNES).Although the cost of a component inside a hydraulic pump, such as a rolling element bearing, rotor or fastener, is often very small compared to the total cost of the pump, the cost of production downtime and any consequential losses as a result of a component failure, are often significant. After implementing an EAM or CMMS1 system, many companies are disappointed to discover that the system provides hardly any useful management information. However, if you ask the same companies what information or performance indicators they exactly need to fulfil and track their maintenance strategy, many of them cannot provide a clear answer.

After implementing an EAM or CMMS1 system, many companies are disappointed to discover that the system provides hardly any useful management information. However, if you ask the same companies what information or performance indicators they exactly need to fulfil and track their maintenance strategy, many of them cannot provide a clear answer. Rocketing energy demands

Rocketing energy demands  When Triumph Motorcycles required a new seal within a three month lead time they turned to Pioneer Weston International, a division of ERIKS UK to develop and supply the seal.

When Triumph Motorcycles required a new seal within a three month lead time they turned to Pioneer Weston International, a division of ERIKS UK to develop and supply the seal. Corus Process Engineering (CPE), part of Corus Northern Engineering Services (CNES) has successfully completed the manufacture and assembly of two, six-metre diameter steel lifting girdles that will be used to remove (lift and tail) the 400-tonne heat exchangers from the reactors at Calder Hall nuclear power plant in Cumbria.

Corus Process Engineering (CPE), part of Corus Northern Engineering Services (CNES) has successfully completed the manufacture and assembly of two, six-metre diameter steel lifting girdles that will be used to remove (lift and tail) the 400-tonne heat exchangers from the reactors at Calder Hall nuclear power plant in Cumbria. Talking to Joel Leonard, the

Talking to Joel Leonard, the