Plant pros often talk about the importance of a maintenance, operations and engineering partnership. In my experience, the discussions commonly center on very general terms such as better communication and understanding. Those issues are important, but we need precise rules and actions to drive that partnership long term.

Plant pros often talk about the importance of a maintenance, operations and engineering partnership. In my experience, the discussions commonly center on very general terms such as better communication and understanding. Those issues are important, but we need precise rules and actions to drive that partnership long term.

When IDCON works on reliability improvement projects, we often start by working with operations and maintenance leadership to lay down the law and agree upon the work process and the rules of the partnership. Once we agree, we create a "rulebook" that all employees can keep in their pocket. I want to share some of the rules I think help drive the partnership behavior in an organization.

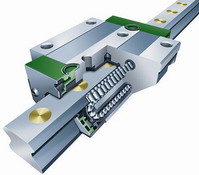

By incorporating special lubricant metering discs on its range of linear recirculating roller bearings and guideway assemblies, Schaeffler has reduced lubricant consumption by more than 25 per cent compared to conventional designs.

By incorporating special lubricant metering discs on its range of linear recirculating roller bearings and guideway assemblies, Schaeffler has reduced lubricant consumption by more than 25 per cent compared to conventional designs. JBJ Techniques has spotted a gap in the market for an effective, simple to use, four-channel process monitor and alarm controller, combined with PC-based visualisation and data logging software. So the company has addressed this requirement by developing its own cost-effective package.

JBJ Techniques has spotted a gap in the market for an effective, simple to use, four-channel process monitor and alarm controller, combined with PC-based visualisation and data logging software. So the company has addressed this requirement by developing its own cost-effective package. As someone involved in the maintenance of a company’s assets, which may include plant machinery, vehicles, long term hire equipment, stock and spares; you will be aware of the bewildering amount of guidance on the subject. You may well be new to the subject having just been delegated to look at your company’s asset portfolio, or given this task in addition to other operations work.

As someone involved in the maintenance of a company’s assets, which may include plant machinery, vehicles, long term hire equipment, stock and spares; you will be aware of the bewildering amount of guidance on the subject. You may well be new to the subject having just been delegated to look at your company’s asset portfolio, or given this task in addition to other operations work. In about 50% of organizations spare parts and materials stores reports to the maintenance organization. In about 50 % of organizations spare parts and materials stores is part of the purchasing function.

In about 50% of organizations spare parts and materials stores reports to the maintenance organization. In about 50 % of organizations spare parts and materials stores is part of the purchasing function. By Paul Dean, CEng, Shire Systems Limited. What

By Paul Dean, CEng, Shire Systems Limited. What  Recently I received an invitation from a well known exhibition organiser to participate in a maintenance feature and submit editorial with company overview- good opportunity. However, my enthusiasm changed to being perplexed when the invitation turned out to be for

Recently I received an invitation from a well known exhibition organiser to participate in a maintenance feature and submit editorial with company overview- good opportunity. However, my enthusiasm changed to being perplexed when the invitation turned out to be for  Heating rail maintenance sheds effectively and economically is a challenge many train companies are now facing with confidence. Nick Winton of AmbiRad Ltd explains.

Heating rail maintenance sheds effectively and economically is a challenge many train companies are now facing with confidence. Nick Winton of AmbiRad Ltd explains.  The Kerrygold Company Ltd has selected Mainsaver to manage engineering maintenance at its new

The Kerrygold Company Ltd has selected Mainsaver to manage engineering maintenance at its new  An effective root cause analysis process can improve production reliability significantly. But, few organizations have a functioning root cause analysis process in place. This article will discuss common problems and some suggested solutions in order to improve root cause problem elimination.

An effective root cause analysis process can improve production reliability significantly. But, few organizations have a functioning root cause analysis process in place. This article will discuss common problems and some suggested solutions in order to improve root cause problem elimination.