.jpg) 1. Abstract

1. AbstractThis paper examines the requirements of PAS 55-1:2008 Asset Management Part 1:

.jpg) 1. Abstract

1. Abstract Use of Wind Energy – Future Development The share of renewable energy sources in total energy consumption is to be increased to 20% in 2020.To achieve this extremely ambitious target, the share of renewable energy sources in electricity generation in the European Union has to be increased to proximately 34% by 2020.

Use of Wind Energy – Future Development The share of renewable energy sources in total energy consumption is to be increased to 20% in 2020.To achieve this extremely ambitious target, the share of renewable energy sources in electricity generation in the European Union has to be increased to proximately 34% by 2020.  The contribution of maintenance to an organisation is unfortunately too often not fully understood until something goes wrong e.g. a failure of a significant plant item or asset.This will inevitably result in a consequential loss through the inability to produce or provide a service or the occurrence of an environmental health, safety or quality incident.

The contribution of maintenance to an organisation is unfortunately too often not fully understood until something goes wrong e.g. a failure of a significant plant item or asset.This will inevitably result in a consequential loss through the inability to produce or provide a service or the occurrence of an environmental health, safety or quality incident.  Problem: Wind turbines by their nature are located in remote locations. Daily monitoring of systems is often an impractical solution.

Problem: Wind turbines by their nature are located in remote locations. Daily monitoring of systems is often an impractical solution.  The Eaubonne Montmorency Hospital Group needed a unified CMMS system to manage the activities of its various departments.

The Eaubonne Montmorency Hospital Group needed a unified CMMS system to manage the activities of its various departments.  Condition monitoring specialists SENSONICS have made an important contribution to the upgrade of turbine supervisory and vibration monitoring installations at the Uskmouth Power Station in Newport, South Wales.

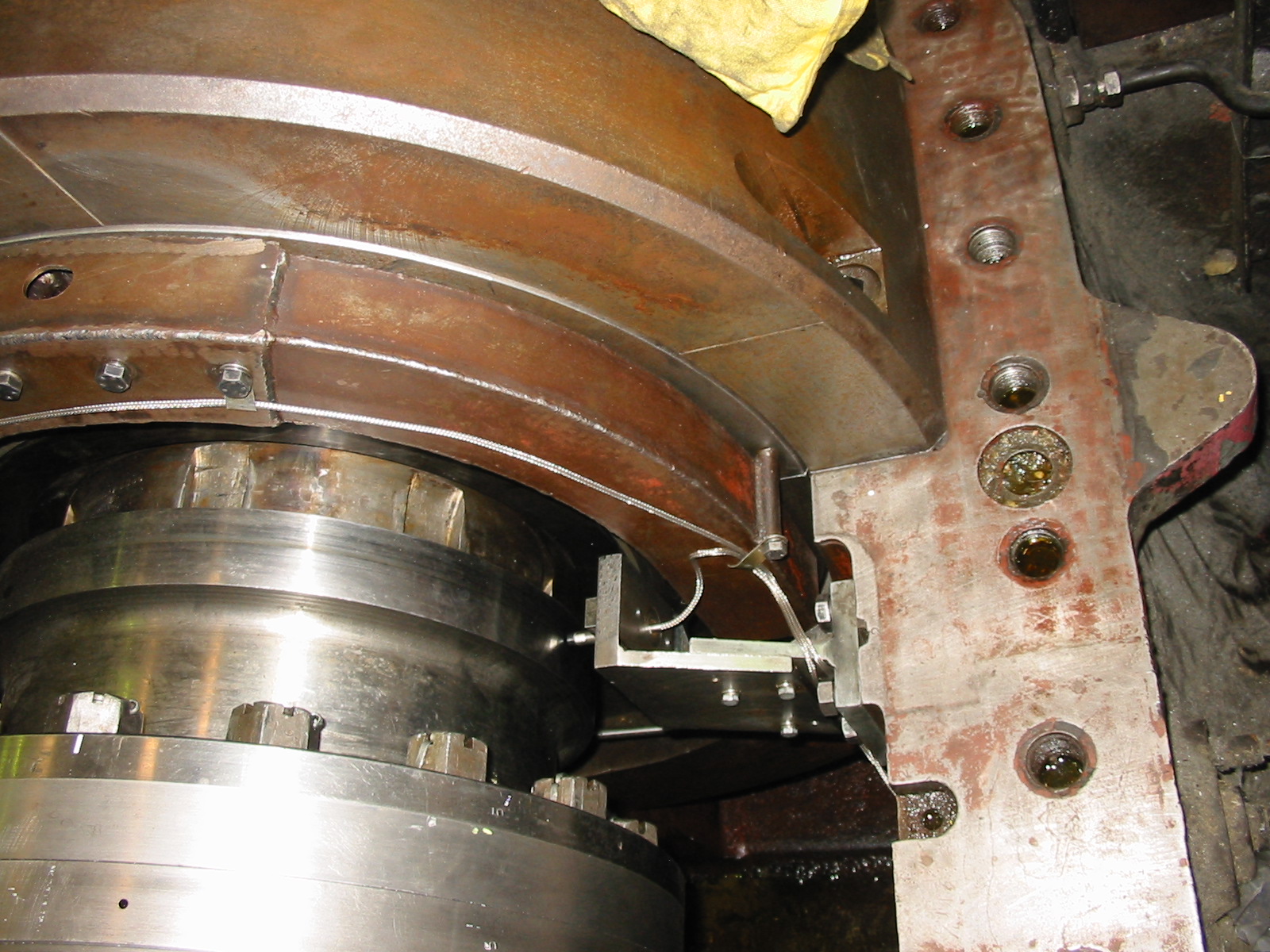

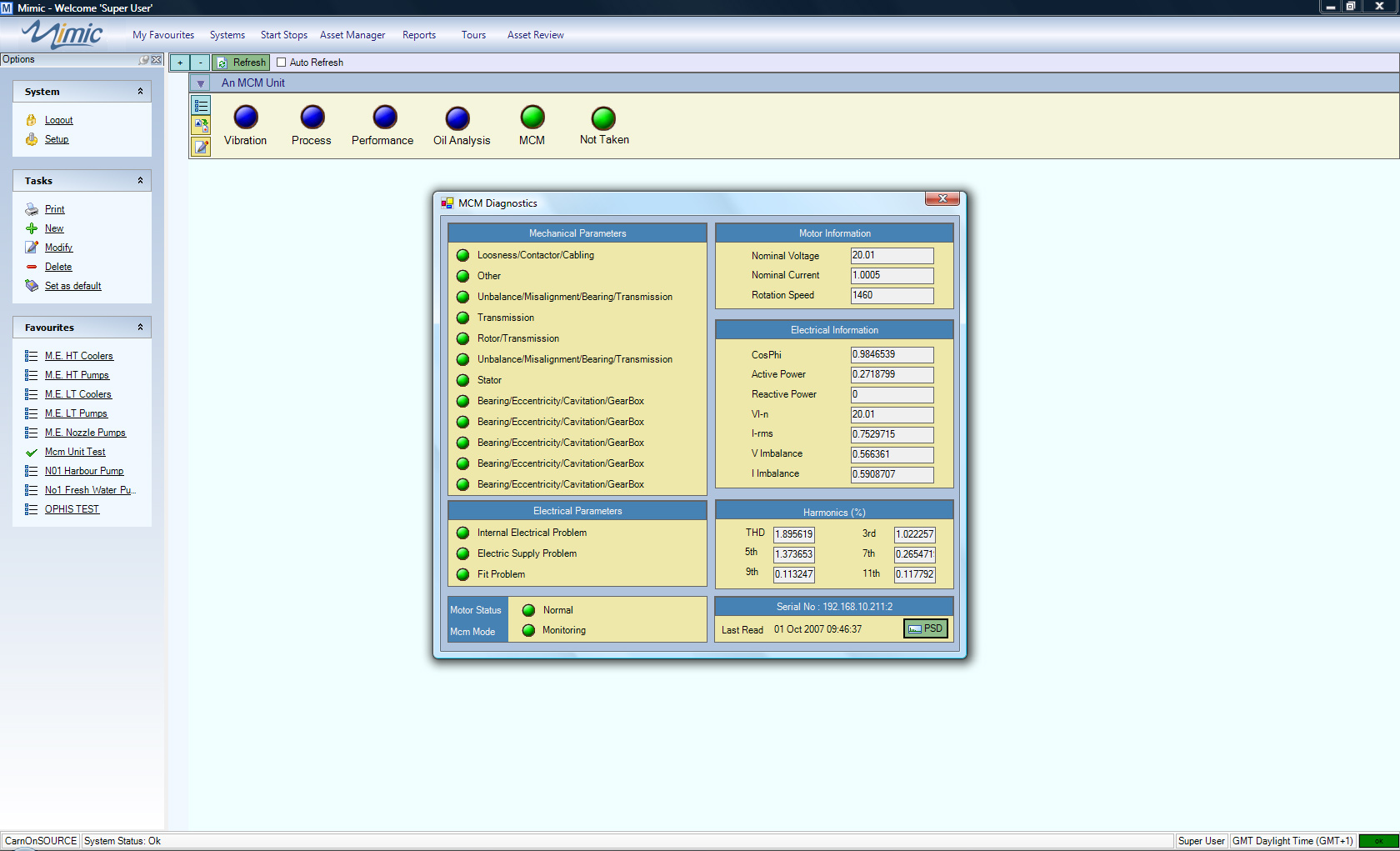

Condition monitoring specialists SENSONICS have made an important contribution to the upgrade of turbine supervisory and vibration monitoring installations at the Uskmouth Power Station in Newport, South Wales.  Artesis, a leading supplier of intelligent predictive maintenance solutions, has recently partnered with marine specialists James Fisher Mimic to integrate

Artesis, a leading supplier of intelligent predictive maintenance solutions, has recently partnered with marine specialists James Fisher Mimic to integrate  In today’s environment, many manufacturers are focusing on total cost of ownership

In today’s environment, many manufacturers are focusing on total cost of ownership The world of equipment maintenance changed dramatically during the second half of the 20th century and it continues to do so today.

Several major influences have been responsible for driving these changes:

Mass unbalance in a rotating system often produces excessive synchronous forces that reduce the life span of various mechanical elements. First of all we will define unbalance case. Unbalance is basically very simple case caused by

Mass unbalance in a rotating system often produces excessive synchronous forces that reduce the life span of various mechanical elements. First of all we will define unbalance case. Unbalance is basically very simple case caused by