Author: Greg Smith, Labtex

Author: Greg Smith, Labtex

In this Labtex White Paper:

• Safety Storage Cabinets Overview

• What must a Safety Storage Cabinet be able to do

• A comparison of the fire resistance of cabinet constructions

• Consequences of the standard in Europe

• Approval documentation

• Conclusion

Safety Storage Cabinets Overview

The European Standard BS EN 14470-1 was implemented in April 2004 and has since been published as a national standard in many European countries including the Netherlands, France, Spain, UK, Italy etc.

In the UK it is recommended that no more than 50 litres of highly flammable solvent be stored in a room using cabinets referred to in such documents as DSEAR 2002 (Dangerous Substances and Explosive Atmospheres Regulations) and HSG 51 from the Health and Safety Executive (Storage of Flammable Liquids in Containers). These normally refer to single skinned metal cabinets manufactured according to BS 476. However, there is an exception which can be found by visiting the website: http://www.hse.gov.uk/fireandexplosion/storageflammliquids.htm

On these web pages it states that subject to a thorough risk assessment, the 50 litre recommendation can be exceeded when using high specification safety cabinets such as those manufactured according to BS EN 14470-1.

There are a number of dangers, risks and disadvantages of using an external store or any haphazard storage system.

When transporting hazardous materials from the centralised storage room to the workplace there is the risk of spillage or other incident. Precious working time is lost when collecting/returning material.

Hazardous materials which are used at the work space are not always returned to the central store and ‘hidden’ quantities of hazardous material develop. In the event of a fire these can contribute to an uncontrollable blaze and the protection of staff and fire fighters can no longer be ensured.

If unknown quantities of hazardous materials are stored, or are in use within the laboratory, applicable regulations and laws may be breached. In case of damage, insurance cover may be lost and an employer is liable for property and damage to persons. In the event of an accident, the loss of production cannot be calculated/foreseen, nor the potential long term loss of reputation.

Safety, protection and the advantages of a workplace with a fire resistant safety storage cabinet

The time spent ‘fetching and carrying’ from the storage room to the workplace is minimised and all hazardous materials for daily use can be readily available safely and conveniently in the lab. There is increased efficiency as there is no need to move flammables in and out from the central storage room.

Type 90 safety cabinets in accordance with EN 14470-1 provide the highest degree of safety for personnel and the environment and give maximum safety to your investment. They guarantee the highest fire protection available today, minimise the potential for explosions and prevent an existing fire from spreading.

A type 90 cabinet provides sufficient time for personnel to safely leave the building and for fire fighters to rescue people from the building and to extinguish a fire.

What must a Safety Storage Cabinet be able to do?

The following points describe the basics and main safety, test and construction requirements.

The primary protection for which a safety storage cabinet is intended is to shield stored, hazardous materials from a temperature rise of more than 180K in the event of fire for the defined period of time.

Combustion may begin if the temperature rise inside the Safety Storage Cabinet exceeds 180K. From this value up, the majority of chemicals reach their ignition temperature and they explode.

Fire is the same in all parts of the world!

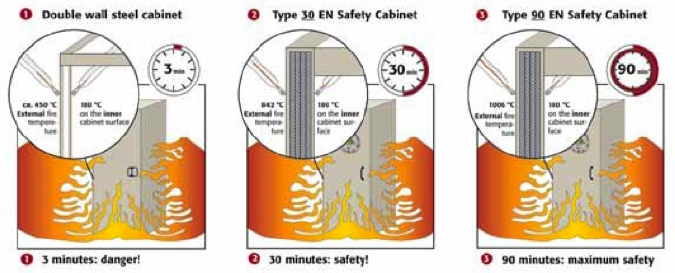

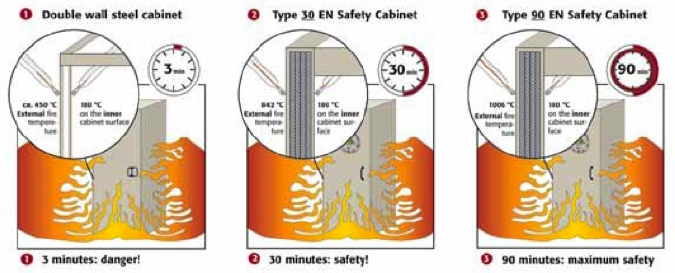

Whether in London or Lisbon, a fire has the same properties and temperatures. A temperature curve shows that after only 5 minutes a fire has reached a temperature of 576°C. After 30 minutes, 842°C has been reached, and after 90 minutes the flames are at more than 1000°C.

The contents of a single skin storage cabinet to BS476 will follow the same temperature curve.

A comparison of the fire resistance of cabinet constructions

A double-wall steel cabinet provides no more than three minutes of protection before the interior has heated to 180°C.

A Type 30 EN Safety Storage Cabinet provides 30 minutes of protection before the interior has heated to 180°C. 10 times more safety in the event of fire compared with a double-wall steel cabinet.

Highest safety is achieved with a Type 90 EN Safety Storage Cabinet. These cabinets provide 90 minutes of protection before the interior has heated to 180°C.30 times more safety in the event of fire and enough time for rescue and fire fighting services to take action.

Fire protection

In the event of a fire the cabinet must ensure that, over a period of time defined by the manufacturer (but in any event at least 15 minutes), its contents do not present an additional risk that the fire will spread. The cabinet doors must close entirely, starting from any position (closing time max. 20 seconds).

Air inlet and outlet openings

The cabinets must have openings for air inlet and outlet (for connection of the cabinet to an exhaust system). The ventilation openings must close automatically at a temperature of 70 °C. Shelves and drawers must be able to support the loading specified by the manufacturer over the period of the test in the furnace. Design evidence of the load-carrying capacity of shelves and drawers in the event of fire based on EN 1365 (fire resistance tests for self-supporting components). The internal equipment of the cabinet must include a spill containment sump and the spill containment sump must retain its ability to function after the fire resistance test. This is to be checked visually by filling the spill containment sump with water.

Fire resistance

Each model must be independently verified by tests on a design sample. The fire resistant cabinet is exposed to flames in a suitable furnace. The doors, walls and ceiling of the cabinet being tested must be exposed to the same heating conditions.

Cabinets must be tested as free-standing single cabinets. The flame exposure is carried out in accordance with the standard temperature curve of BS EN 1363-1 (5.1.1).

The temperature rise is measured inside the cabinet.

The cabinet will then be classed as type 15, 30, 60 or 90, according to the time that has elapsed before the temperature rose by 180 K.

EN 14470-2. The standard for gas cylinder cabinets

Maximum safety in the storage, provision and withdrawal of gas cylinders in indoor areas.

Due to the positive pressure and the contents (corrosive, toxic, inflammable, fire accelerating), gas cylinders represent a hazard potential. It is therefore usually recommended to store gas cylinders in outdoor areas. In practice this is often not possible or is associated with very high costs.

With the publishing of the new European standard for gas cylinder cabinets, EN 14470-2, an economical and flexible option for the installation of gas cylinders in indoor areas is now available that offers a level of safety comparable to that of outdoor storage.

Consequences of the standard in Europe

Fire resistance is classified into 4 classes from G15 up to G90 (fire resistance of 15 up to 90 minutes).

Each type of cabinet and each cabinet size must to be type tested in a furnace. In case dimensional variation exceeds the tolerance, the cabinet has to be retested again. Tests can only be executed by an authorised material testing institute. Cabinets must be tested in a furnace as free-standing single cabinets.

BS EN 14470-2 stipulates declaration of conformity or certificates of conformity be supplied with each cabinet delivery.

Approval Documentation

Complete approval documentation for each safety storage cabinet includes:

1. A test report of an authorised material testing institute stating/proving the successfully passed fire test.

2. Test certificate by an independent testing organisation and declaration of CE conformity by the manufacturer

This ensures compliance with regulations, safety for the user and clear identification of approval documents with the model of safety storage cabinet.

asecos - Standard for safety and quality

1. Testing certificates of an authorised material testing institute for each cabinet. Approved fire resistance in accordance with EN 14470-1.

2. Verification for all cabinet models on observing the Equipment and Product Safety Law. Documented in the testing certificates by independent testing organisations.

3. CE approval certificates for each cabinet model. Verification that all relevant European guidelines are observed.

4. Quality Management in accordance to DIN EN ISO 9001. Asecos quality from the quotation to the delivery.

Conclusion

BS EN 14470-1 and BS EN 14470-2 are product specifications giving performance requirements of safety cabinets for internal storage of flammable and other hazardous products.

For maximum safety, efficient working practises and to keep one step ahead of legislation these cabinets have no equal.

Contacts

Labtex is a specialist laboratory and process chemistry equipment solutions provider.

A dynamic team of professionals with expertise in research and process development across a wide range of industries and disciplines.

You will find that talking to Labtex is a breath of fresh air. No complicated telephone system, just real people ready to react professionally to your enquiry. We pride ourselves on our customer service based on quick response, accurate informed advice and attention to detail.

Labtex,

Dogley Mills, Penistone Road, Fenay Bridge, Huddersfield,

West Yorkshire, United Kingdom HD8 0LE

Tel: 01484 600200

Fax: 01484 607390

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web: www.labtex.co.uk

Is your Pollution Prevention Watertight?

Is your Pollution Prevention Watertight?

Introduction

Introduction Peter Swan, MD of SBES, examines an often-overlooked issue

Peter Swan, MD of SBES, examines an often-overlooked issue Peter Swan, MD of SBES, examines an often-overlooked issue

Peter Swan, MD of SBES, examines an often-overlooked issue Molten sulfur is present in an ever widening range of industries and liquid sulfur storage tanks are used worldwide in crude oil refineries and natural gas plants to store liquid sulfur in very large volumes. Sulfur storage tanks are most commonly utilised as part of the Gas Treating System in sour crude oil refineries and gas sweetening facilities to temporarily store liquid sulfur produced in the sulfur recovery plant. These tanks are usually field erected and most commonly constructed of carbon steel.

Molten sulfur is present in an ever widening range of industries and liquid sulfur storage tanks are used worldwide in crude oil refineries and natural gas plants to store liquid sulfur in very large volumes. Sulfur storage tanks are most commonly utilised as part of the Gas Treating System in sour crude oil refineries and gas sweetening facilities to temporarily store liquid sulfur produced in the sulfur recovery plant. These tanks are usually field erected and most commonly constructed of carbon steel. By Ulf Persson, Technical Manager (Europe), Camfil Air Pollution Control

By Ulf Persson, Technical Manager (Europe), Camfil Air Pollution Control Free White Paper

Free White Paper How can you manufacture explosion-proof equipment and systems to world-class safety requirements?

How can you manufacture explosion-proof equipment and systems to world-class safety requirements? Author: Greg Smith, Labtex

Author: Greg Smith, Labtex

Close collaboration between two Northumberland engineering companies has resulted in the production of a unique marine vessel which is certified for work in the most extreme Hazardous Areas.

Close collaboration between two Northumberland engineering companies has resulted in the production of a unique marine vessel which is certified for work in the most extreme Hazardous Areas.