The topic of “explosion safety” is omnipresent for plant operators and OEM´s when it comes to handling or transporting combustible dusts. Despite the widespread assumption that an increased risk of explosion only exists for gases, enormous forces can also be released by explosive dust- / air mixtures.

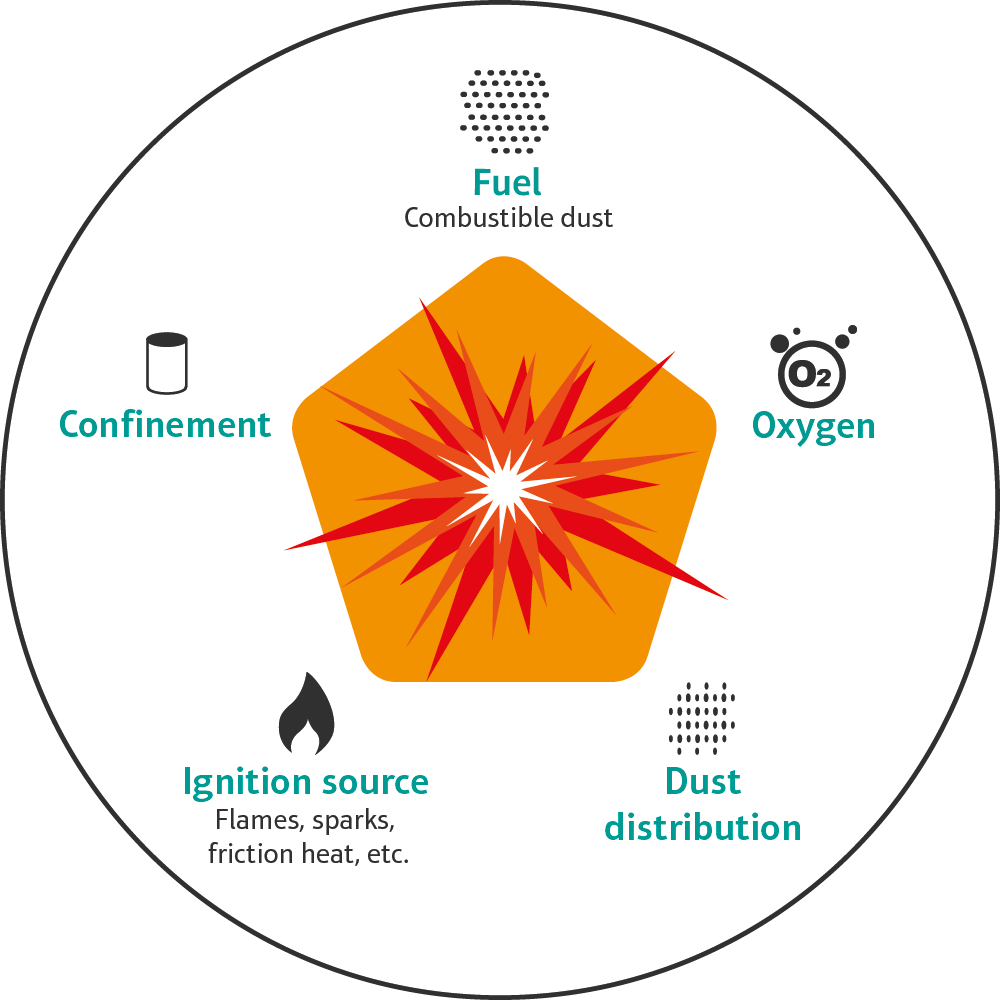

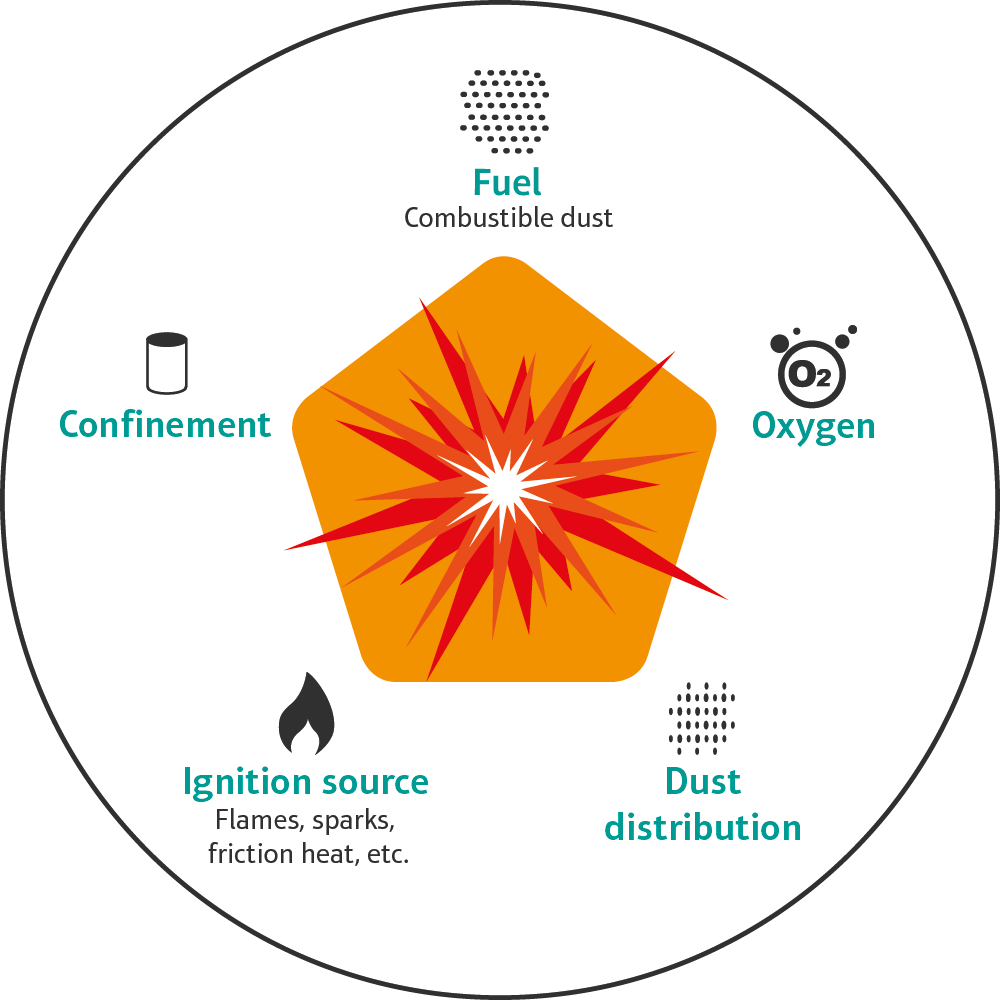

To help minimise the risk of explosions when handing combustible dusts, it is important to understand the requirements for an explosion and the respective dust safety characteristics, which are described below. The following picture shows the fire triangle and the explosion pentagon which must be taken into account.

The following conditions must exist for an explosion to occur within a production facility or machine:

Fig. 1: Explosion pentagon

If any one of the aforementioned prerequisites is eliminated, explosion prevention has intrinsically been practised. However, if this is not possible at all times and in all operating states, explosion hazards will still be present. In this case, it is necessary to divide any potentially explosive atmospheres into zones and systematically apply safety measures.

Drying processes in particular are used in many industries to produce material, for easier storage, more efficient transport and a longer shelf life. However, the combination of moisture extraction and high temperatures creates an increased risk of both, fires and explosions.

If fires and/or explosions occur in drying plants, which are usually very large, the situation is not only extremely dangerous for the machines and the business, but especially for the employees on site.

Operators of spray dryers must combat a particular type of ignition source – namely smouldering nests that can lead to spontaneous combustion if the material undergoes excessive caking. Caking occurs due to sub-optimal drying of the material and its initially high moisture content. The caked material is then insulated against the surrounding air by a build-up of moist material. The high temperatures ensure that the caked material is continuously heated until a biological reaction takes place involving protein, carbohydrate and water – known as the Maillard reaction. The Maillard reaction generates additional heat that cannot be dissipated due to the insulating layer of caked material. This process continues to accelerate until spontaneous combustion finally occurs.

Caking of this kind can build up both on the nozzles and the inner wall of the spray dryers. If the nozzle malfunctions, droplets may fall down into the fluid bed and cause further clumping. If a smouldering nest is able to form, this can ignite the explosive atmosphere inside the dryer or the downstream machinery.

How can such conditions, which are frequently encountered in practice, be prevented?

Everything starts with the human factor, i.e. properly trained personnel for the respective processes. Optimal process control is also required to avoid caking. But without precise and reliable information/measurements, this is virtually impossible, even for specialists. Nowadays, humidity and one of the by-products of spontaneous combustion at early stages – carbon monoxide (CO) – are used as indicators to ensure a smooth and thus safe process. However, the fact that combined measurement systems cannot clearly distinguish between these two indicators is problematic and can result in inaccurate measurements.

The REMBE CO.Pilot makes exactly this symbiosis possible!

Via a permanent comparison of recorded data with a database of stored reference gases that serve as "fingerprints" of the selected gases, it is possible to perform a one-time check in real time and thus permanently verify the measurement accuracy. At the same time, the real-time fingerprint analysis eliminates the cross-sensitivity to other gases in the measurement spectrum that is common in commercial gas analysers.

To ensure a reliable measurement of the operating status, samples are sucked in from all of the dryer's relevant supply and exhaust air ducts under very high vacuum. REMBE calculates the delta CO value on the basis of the absolute values measured at the individual measuring points. This value is the mathematical difference between the CO content of the extract air and the CO content of the supply air. Thus, only events that actually occur in the respective process are detected. External factors that may disturb the process can thus be ignored.

A proprietary evaluation algorithm (RFA REMBE Flow Algorithm) enables the measured supply and exhaust air values to be compared in real time. As a result, the REMBE CO.Pilot is the first system on the market that makes it possible to adjust the individual alarm limits and gas run times for the individual measuring points in the dryer's various air throughputs without any delays. The ratios of the different supply air channels and the flexible operating hours are balanced via the software and calculated accordingly in the PLC.

Thus, if an increased carbon monoxide concentration is detected due to spontaneous combustion during the process, countermeasures can be initiated immediately.

But what does this mean in detail?

This special sampling process eliminates the need for costly and error-prone gas treatment, thus ensuring that the CO.Pilot is less susceptible to faults and requires less maintenance. Furthermore, this measurement method can make recurring calibrations unnecessary. Due to the precise measurement technology and the reproducible results, false alarms and downtimes can also be avoided. And in combination with moisture measurements, the entire drying process can be optimally controlled, significantly increasing the energy efficiency of the system.

Fig. 2: REMBE CO.Pilot

About REMBE – the REMBE Alliance introduces itself

Most people associate REMBE with REMBE GmbH Safety+Control, the specialist for explosion safety and explosion venting worldwide. The company offers customers cross-industry safety concepts for plants and equipment. All products are manufactured in Germany and meet the requirements of national and international regulations. REMBE customers include market leaders in various industries, including the food, timber, chemical and pharmaceutical industries.

The company’s engineering expertise is based on almost 50 years of application and project experience. As an independent, owner-managed family business, REMBE combines expertise with the highest quality standards and is involved in various specialist committees worldwide. Short coordination paths allow for quick reactions and customer-specific solutions for all applications, from standard products to high-tech special designs.

In addition to REMBE GmbH Safety+Control (www.rembe.de) with approx. 300 employees worldwide, headquartered in Brilon (Hochsauerland, Germany), and numerous subsidiaries worldwide (Italy, Finland, Brazil, USA, China, Dubai, Singapore, South Africa, Japan), four other companies operate under the REMBE umbrella brand: