Two of the world’s leading companies in VOC detection will launch an informative on-demand (free) webinar available now. Speakers from both ION Science and Industrial Scientific will describe what VOCsare, why they should be monitored,what detection techniques are suitable, and where and when measurements should be undertaken.

The webinar speakers will be Ilaria Tramelli, Business Development Director for PID, at Industrial Scientific, and Peter Morris, Head of Sensors at ION Science. “This webinar will be an ideal learning opportunity for anyone with responsibility for health, safety or the environment in almost any industry,” explains the webinar host, Emily Lane, Marketing Manager at ION Science Ltd, “VOCs occur in most industrial sectors, but their relative toxicity varies widely, and there are a number of ways in which they can be detected, so this webinar has been designed to provide the core knowledge that is necessary for VOCs to be managed effectively.”

The on-demand webinar lasts for around 30minutes and can be accessed, free of charge, by visiting

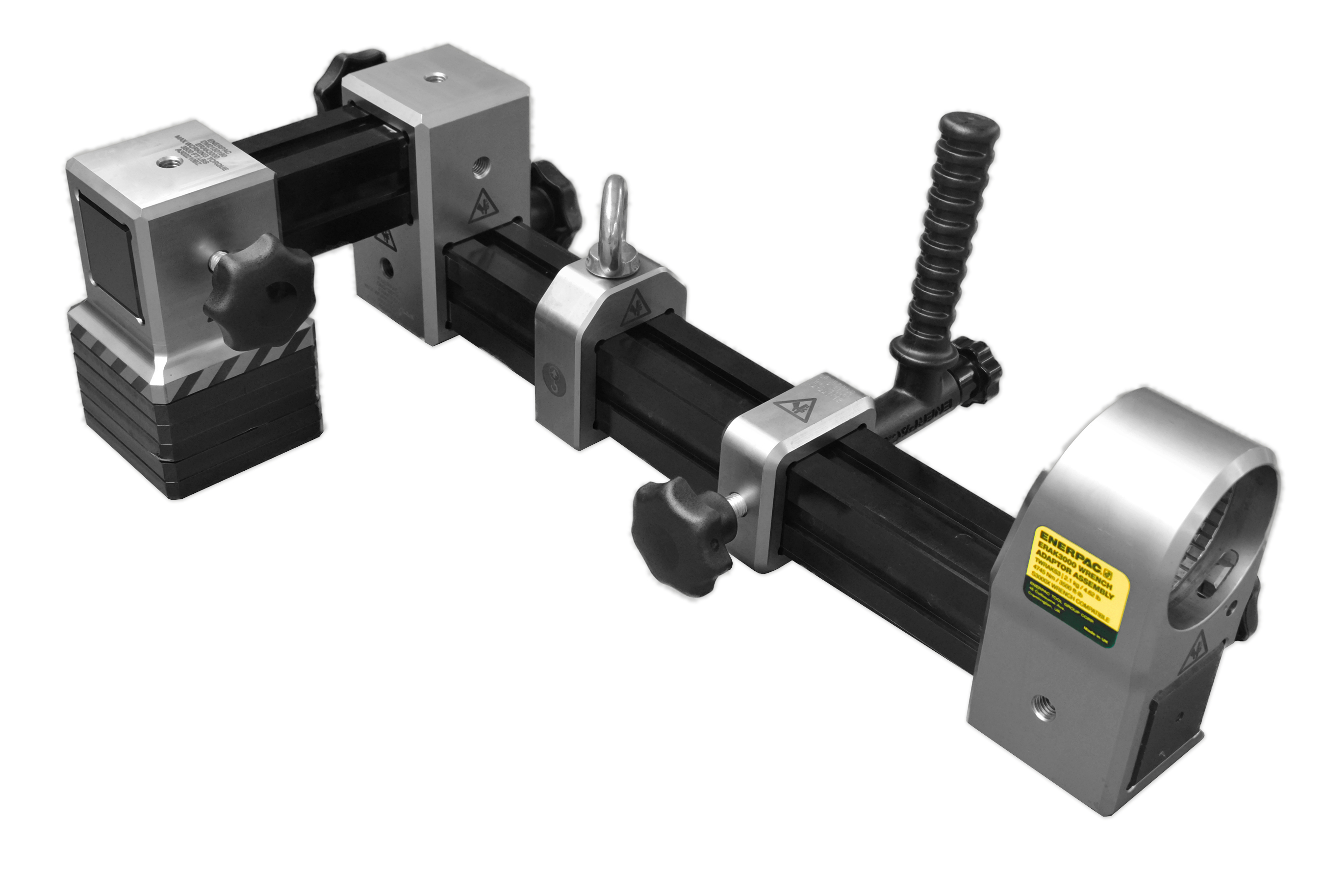

The main objective of the webinar is to provide educational content that contributes to the professional development of viewers. Whilst explaining the advantages and disadvantages of different detection technologies, the speakers will also describe the unique aspects of the ION Science MiniPIDs that make them ideal for OEM integration for accurate and reliable VOC detection.

The speakers will also describe the most common applications for VOC detection; providing insights into the factors which can lead to potentially dangerous concentrations of VOCs. Pete will also describe the increasing use of PIDs in low-cost, (sometimes mobile) spatially dense ambient air quality monitoring networks and in indoor air quality monitoring; an area of growing concern post-Covid. In addition, Ilaria will explain the requirement for first responders to be able to quickly assess the levels of danger following an incident or accident involving hazardous materials.

Given the fast response, sensitivity and wide range of VOCs detected by ION’s MiniPID, their inclusion in the Industrial Scientific products is a major benefit. Laura Faust, Product Manager atIndustrial Scientific says: “The Ventis Pro 5 multi-gas monitor gives you the power to monitor up to five gases simultaneously and with multiple connectivity options, you can manager worker safety anytime, anywhere. Now with the addition of the PID sensor, you can protect workers from volatile organic compounds (VOCs) with the same compact personal monitor. This valuable addition brings us one step closer to our vision of ending workplace deaths by 2050.”

After viewing the webinar, attendees should have a better understanding of what VOCs are, what their acute and chronic health effects are, and how they affect the environment. They will also be aware of the different detection techniques that are available, and their relative advantages and disadvantages. This should include an understanding of the reasons why PID is the most commonly accepted method for VOC detection.