Hosokawa Micron Ltd are now able to offer HEPA Filter Integrity Tests either as a specific task or as part of a planned maintenance programme.

Industry recommends that HEPA filters be checked at 14 month intervals or less or immediately after filter change. This is because where high efficiency filters are fitted, it is important that the filter housing/sealing device does not allow particulate material to pass and therefore compromise the classification of the controlled environment installation that is being served.

The Filter Integrity Test is commonly referred to as a DOP test because the original smoke used in the test was generated using Di-Octyl Phthalate. This chemical was found to have carcinogenic properties and was subsequently substituted by a mineral oil, Shell Ondina EL. The smoke generated from this has identical characteristics and the term DOP testing remains, although it is now understood to mean

Introduction

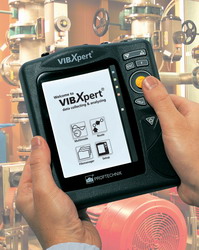

Introduction PRÜFTECHNIK, the vibration analysis specialists have introduced a new FFT analyzer and data collector to their range of condition monitoring systems.

PRÜFTECHNIK, the vibration analysis specialists have introduced a new FFT analyzer and data collector to their range of condition monitoring systems. PRÜFTECHNIK Condition Monitoring presents the VIBROWEB; a new, automated monitoring and diagnosis system for production-critical machines and systems.

PRÜFTECHNIK Condition Monitoring presents the VIBROWEB; a new, automated monitoring and diagnosis system for production-critical machines and systems. Unfortunately, when it comes to steam traps, people often ignore them. There

Unfortunately, when it comes to steam traps, people often ignore them. There A new, versatile and comprehensive handheld machine condition analyser is launched by SPM Instrument AB, Sweden.

A new, versatile and comprehensive handheld machine condition analyser is launched by SPM Instrument AB, Sweden. A new variant of the MG4 has been introduced. Called MG4-Ref11, it has been developed for the pulp and paper industry for continuous monitoring of refiners.

A new variant of the MG4 has been introduced. Called MG4-Ref11, it has been developed for the pulp and paper industry for continuous monitoring of refiners. The Schaeffler Group

The Schaeffler Group Since 2002, customers worldwide have avoided failures of their equipment, from vital production equipment to the office air conditioning, by using Artesis

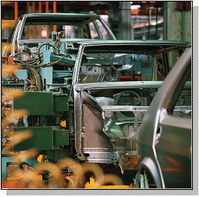

Since 2002, customers worldwide have avoided failures of their equipment, from vital production equipment to the office air conditioning, by using Artesis Rustem Yildiz is maintenance manager responsible for the Gebze plant which supplies Daimler-Chrysler, Ford, Toyota and Honda on a Just-in-Time basis. From his office, he can access data on the current condition of all the equipment monitored by the Artesis MCM units, and is automatically notified of any changes in status, indicating a potential deterioration in performance. In addition to the excellent downtime figures, he measures the success of the system by a significant improvement in his homelife, resulting from a dramatic reduction in the number of out of hours calls he receives, that previously had disrupted his evenings.

Rustem Yildiz is maintenance manager responsible for the Gebze plant which supplies Daimler-Chrysler, Ford, Toyota and Honda on a Just-in-Time basis. From his office, he can access data on the current condition of all the equipment monitored by the Artesis MCM units, and is automatically notified of any changes in status, indicating a potential deterioration in performance. In addition to the excellent downtime figures, he measures the success of the system by a significant improvement in his homelife, resulting from a dramatic reduction in the number of out of hours calls he receives, that previously had disrupted his evenings.