The first choice of thousands of asset maintenance, estates and facilities professionals. Remarkable functionality and amazing value for money.

The first choice of thousands of asset maintenance, estates and facilities professionals. Remarkable functionality and amazing value for money.

Overview

Stop fire fighting and gain control of your workload, service delivery and maintainable assets using FrontLine. Minimise costs, meet safety and environmental goals and hit your operational and business targets.

FrontLine is a fully featured, universal tool. FrontLine can be used to deploy maintenance strategy and control maintenance and repair work in a multitude of sectors. Any type of organisation can use FrontLine to gain business advantage from asset maintenance. Whether you are handling your own internal maintenance, or you are a contractor providing services to a client, FrontLine is the answer to your professional and business needs.

By installing bearing lubricators and vibration monitoring equipment on its production machinery, chewing gum maker Gumlink has eliminated bearing defects and unplanned stoppages.

By installing bearing lubricators and vibration monitoring equipment on its production machinery, chewing gum maker Gumlink has eliminated bearing defects and unplanned stoppages. More than just a supplier of bearings, Schaeffler UK is now offering customers a full design and manufacturing service from its Llanelli plant. Corus

More than just a supplier of bearings, Schaeffler UK is now offering customers a full design and manufacturing service from its Llanelli plant. Corus Current solid oxide fuel cell systems (SOFCs) produce a typical power range of 1-5kW, far from sufficient to meet the multi-megawatt demands placed on a commercial power plant.

Current solid oxide fuel cell systems (SOFCs) produce a typical power range of 1-5kW, far from sufficient to meet the multi-megawatt demands placed on a commercial power plant. The BPF is a key source of expertise and information on Health and Safety issues as they relate to the plastics sector. The Federation is dedicated to ensuring that Health and Safety within the plastics industry shows continuing improvement and that employees are appropriately protected:

The BPF is a key source of expertise and information on Health and Safety issues as they relate to the plastics sector. The Federation is dedicated to ensuring that Health and Safety within the plastics industry shows continuing improvement and that employees are appropriately protected: Proviso Systems Ltd is a company that takes its mission very seriously to change the way the UK performs maintenance. We are committed to offering "Total Service Solutions" to your industry. Based upon extensive industrial knowledge, the Directors and staff of Proviso Systems recognise that now is the time for a totally innovative approach to condition monitoring and the field of predictive maintenance.

Proviso Systems Ltd is a company that takes its mission very seriously to change the way the UK performs maintenance. We are committed to offering "Total Service Solutions" to your industry. Based upon extensive industrial knowledge, the Directors and staff of Proviso Systems recognise that now is the time for a totally innovative approach to condition monitoring and the field of predictive maintenance.  Lately, there has been a stream of visitors to the Dearborn Stamping Plant (DSP) housed in the historic Ford Rouge Center in Dearborn,Michigan. What's the attraction?

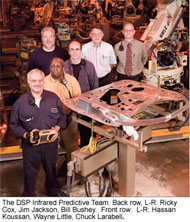

Lately, there has been a stream of visitors to the Dearborn Stamping Plant (DSP) housed in the historic Ford Rouge Center in Dearborn,Michigan. What's the attraction? Wyatt Partney, senior controls systems technician at Eastman

Wyatt Partney, senior controls systems technician at Eastman