A & B Air Systems and BEKO TECHNOLOGIES have helped lower costs at a leading European food manufacturer. Their customers are most of the leading high street food chains.

A & B Air Systems and BEKO TECHNOLOGIES have helped lower costs at a leading European food manufacturer. Their customers are most of the leading high street food chains.

The quality of compressed air is always an important topic in food production. At one site there are 2 compressor systems; the high quality oil free and dried to -40°C pressure dew point for the air which is in contact with the product and a general purpose stream for operation of pneumatic components which comes from lubricated compressors with filters to 0.01ppm oil carry over and +3°C pressure dew point.

Compressed air is said to be responsible for approximately 10% of the power usage in the UK and other mature economies. BEKO TECHNOLOGIES are a leading company in the treatment of compressed air and management of condensates. Another major part of the business is measurement systems. BEKO TECHNOLOGIES are well equipped with experienced technical sales personnel to help businesses improve their efficiency of compressed air usage. We have put together a list of top tips:

Compressed air is said to be responsible for approximately 10% of the power usage in the UK and other mature economies. BEKO TECHNOLOGIES are a leading company in the treatment of compressed air and management of condensates. Another major part of the business is measurement systems. BEKO TECHNOLOGIES are well equipped with experienced technical sales personnel to help businesses improve their efficiency of compressed air usage. We have put together a list of top tips: In the field of condensate technology, there is also news at the COMVAC HANNOVER 2013 at BEKO TECHNOLOGIES: the upgrade version of the BEKOMAT 31, 32, and 33 condensate drains with improved serviceability.

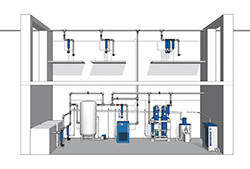

In the field of condensate technology, there is also news at the COMVAC HANNOVER 2013 at BEKO TECHNOLOGIES: the upgrade version of the BEKOMAT 31, 32, and 33 condensate drains with improved serviceability.  At the COMVAC HANNOVER, BEKO TECHNOLOGIES presented the innovative variant of the EVERDRY FRA-V 2000C adsorption dryer. The special feature of this design is the modular concept, which allows for the separation of the adsorber containers from the pipework module, and for the reconnection in just a few steps. Through this structure, even larger plants can be packed in standard sea containers. This drastically reduces the transport and packaging costs and offers optimum protection to the plant during long sea journeys.

At the COMVAC HANNOVER, BEKO TECHNOLOGIES presented the innovative variant of the EVERDRY FRA-V 2000C adsorption dryer. The special feature of this design is the modular concept, which allows for the separation of the adsorber containers from the pipework module, and for the reconnection in just a few steps. Through this structure, even larger plants can be packed in standard sea containers. This drastically reduces the transport and packaging costs and offers optimum protection to the plant during long sea journeys. FAST

FAST Key benefits:

Key benefits: He ain’t heavy, he’s my big BEKOMAT brother

He ain’t heavy, he’s my big BEKOMAT brother The Food and Beverage Grade Compressed Air Best Practice Guideline 102 is available from the British Compressed Air Society and contributing members such as BEKO TECHNOLOGIES. This best practice guideline has been produced because compressed air is a utility and as such its provision is normally included in the pre-requisite programme rather than the HACCP process. There was also an opportunity to review and update the guideline.

The Food and Beverage Grade Compressed Air Best Practice Guideline 102 is available from the British Compressed Air Society and contributing members such as BEKO TECHNOLOGIES. This best practice guideline has been produced because compressed air is a utility and as such its provision is normally included in the pre-requisite programme rather than the HACCP process. There was also an opportunity to review and update the guideline. The iPad 3 from Apple is still on the road to success. Now our clients can take advantage of an application from BEKO TECHNOLOGIES. Since last year on Apple's App Store our popular customer magazine BEKOWORLD (24,000 readers in Germany) is available for free – we have now completed the English edition of the magazine. The application has an additional value from its almost complete downloadable stock of brochures and operating manuals.

The iPad 3 from Apple is still on the road to success. Now our clients can take advantage of an application from BEKO TECHNOLOGIES. Since last year on Apple's App Store our popular customer magazine BEKOWORLD (24,000 readers in Germany) is available for free – we have now completed the English edition of the magazine. The application has an additional value from its almost complete downloadable stock of brochures and operating manuals.  Surely it’s easy there are fridge dryers for 3°C Pressure Dew Point and desiccants for anything below that? In principle “Yes” says Chris Norris UK Service Manager for BEKO TECHNOLOGIES. “There are umpteen different ways to take it further than this simple rule. The client should ask himself several questions such as:-

Surely it’s easy there are fridge dryers for 3°C Pressure Dew Point and desiccants for anything below that? In principle “Yes” says Chris Norris UK Service Manager for BEKO TECHNOLOGIES. “There are umpteen different ways to take it further than this simple rule. The client should ask himself several questions such as:-