It was in 1816 that the Revd. Robert Stirling propounded the idea of a heat engine which he termed an ‘Economiser’ now universally known as a ‘Stirling Engine’. The operational concept is that it acted as a heat exchanger, retaining heat from the hot portion of the engine as air passed to the cold side, and released heat to the cooled air as it returned to the hot side and in the process converting energy to mechanical work, with near perfect efficiency.

It was in 1816 that the Revd. Robert Stirling propounded the idea of a heat engine which he termed an ‘Economiser’ now universally known as a ‘Stirling Engine’. The operational concept is that it acted as a heat exchanger, retaining heat from the hot portion of the engine as air passed to the cold side, and released heat to the cooled air as it returned to the hot side and in the process converting energy to mechanical work, with near perfect efficiency.Stirling engines were widely developed in the 19C until the advent of the electric motor superseded it. Modern versions of the engine are in existence, having been used for specialist civil and military applications. But the need for the development of alternative power sources and the availability of modern technology and materials have resulted in renewed interest and exciting developments in this area.

Bombardier Transportation has its global headquarters in Berlin, Germany with a presence in over 60 countries. It has an installed base of over 100,000 vehicles worldwide.

Bombardier Transportation has its global headquarters in Berlin, Germany with a presence in over 60 countries. It has an installed base of over 100,000 vehicles worldwide.  Steelmakers Corus (Port Talbot) had been experiencing problems with their 42” edger drive system. The existing gear units were only providing 41 rpm when a drive speed of 59 rpm was required. Added to this, Corus’ Area Engineer Craig Dummer stated that “they were experiencing heavy vibration and ultimately, damage to the gear units”.

Steelmakers Corus (Port Talbot) had been experiencing problems with their 42” edger drive system. The existing gear units were only providing 41 rpm when a drive speed of 59 rpm was required. Added to this, Corus’ Area Engineer Craig Dummer stated that “they were experiencing heavy vibration and ultimately, damage to the gear units”. Softstart UK has recently completed the development of a new range of Digital Medium Voltage Soft Starters, designed suitable for all types of induction motors, including synchronous and slip-ring types. The new Digitstart range covers both 3.3kV and 6.6kV in ratings from 60A to 700 Amps and features a completely new programming and monitoring regime. Clearly starting motors in this category needs well considered programming and sensitive protection.

Softstart UK has recently completed the development of a new range of Digital Medium Voltage Soft Starters, designed suitable for all types of induction motors, including synchronous and slip-ring types. The new Digitstart range covers both 3.3kV and 6.6kV in ratings from 60A to 700 Amps and features a completely new programming and monitoring regime. Clearly starting motors in this category needs well considered programming and sensitive protection.  When BOC Gases Ireland decided to update the inefficient existing worm and wheel drives for their cooling tower fans in Cork and Dublin, the question of which supplier to approach was easily answered

When BOC Gases Ireland decided to update the inefficient existing worm and wheel drives for their cooling tower fans in Cork and Dublin, the question of which supplier to approach was easily answered  Energy and fuel conservation has been one of the worlds most talked about topics for a number of years. Whether it be the need to conserve fuel and increase the MPG from your car, or simply turning off the lights and appliances when you go to bed to save energy, companies, organisations and governments the world over are all pushing efficiency initiatives and their green credentials. This drive has stimulated the growth of innovations for UK based manufacturer Midland-ACS.

Energy and fuel conservation has been one of the worlds most talked about topics for a number of years. Whether it be the need to conserve fuel and increase the MPG from your car, or simply turning off the lights and appliances when you go to bed to save energy, companies, organisations and governments the world over are all pushing efficiency initiatives and their green credentials. This drive has stimulated the growth of innovations for UK based manufacturer Midland-ACS. The Schaeffler Group has launched a new range of synchronous linear motors that offer peak loads of 13,000N and deadweight of 45kg, ideal for use on large machining centres.

The Schaeffler Group has launched a new range of synchronous linear motors that offer peak loads of 13,000N and deadweight of 45kg, ideal for use on large machining centres. Thanks to the engineering expertise at Tentec, Hansen Transmissions, one of the world

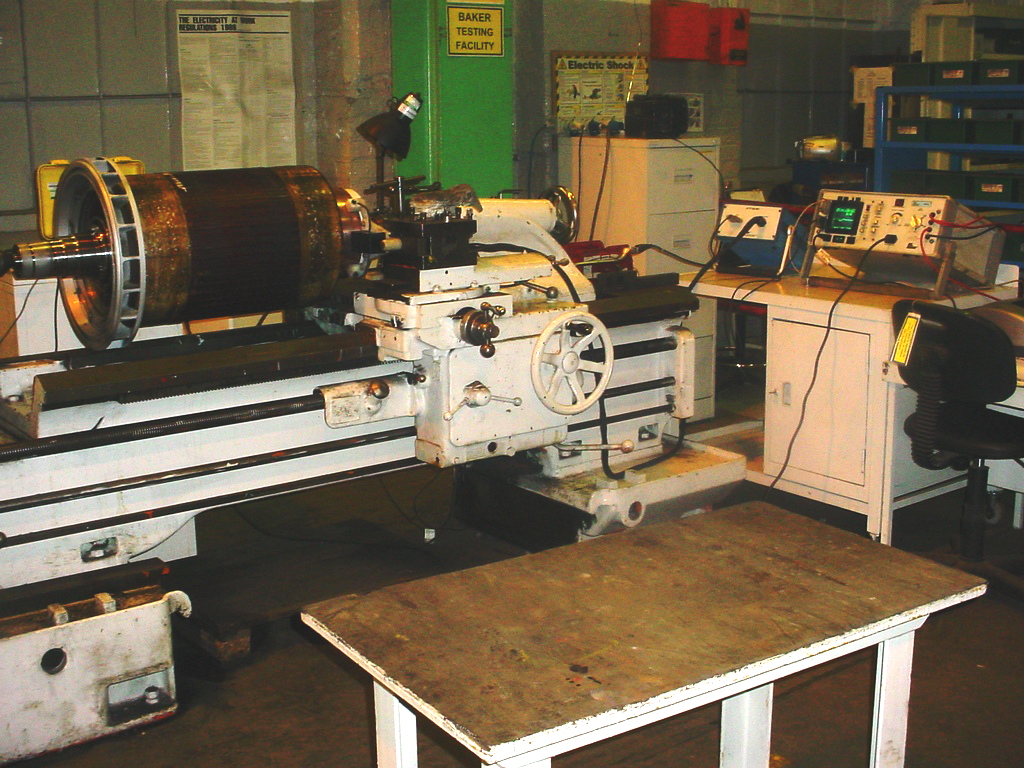

Thanks to the engineering expertise at Tentec, Hansen Transmissions, one of the world For process manufacturing companies, the replacement, repair, servicing and maintenance of electrical equipment that is located within a potentially explosive atmosphere, is often time consuming and costly.Today, around 65% of all electrical maintenance carried out is corrective action and 35% is preventive. With preventive maintenance, more than 50% of all apparatus serviced is not actually broken.

For process manufacturing companies, the replacement, repair, servicing and maintenance of electrical equipment that is located within a potentially explosive atmosphere, is often time consuming and costly.Today, around 65% of all electrical maintenance carried out is corrective action and 35% is preventive. With preventive maintenance, more than 50% of all apparatus serviced is not actually broken. The Huco Dynatork MS worm gearbox with integral torque limiter is a great product for safeguarding machinery and the people that operate it. It stops rotation of the low-speed shaft whenever the stall torque exceeds the calibrated value of the internal torque limiter. Of course, in the event of a power cut this safety gearbox effectively locks and in the majority of applications this is an appropriate consequence. For others however it is a disadvantage.

The Huco Dynatork MS worm gearbox with integral torque limiter is a great product for safeguarding machinery and the people that operate it. It stops rotation of the low-speed shaft whenever the stall torque exceeds the calibrated value of the internal torque limiter. Of course, in the event of a power cut this safety gearbox effectively locks and in the majority of applications this is an appropriate consequence. For others however it is a disadvantage.