As someone with responsibility for the compressed air system, you will be expected to guarantee air at the right pressure and flow, but also at least cost. To do this there are two aspects: you need to produce and use compressed air as efficiently as possible. Disproportionate emphasis on efficient generation of compressed air in the compressor house, may lead to other factors such as the value of effective maintenance and user behaviour being overlooked. Here the role of maintenance in a reliable and energy efficient system.

Compressed air systems rely on effective maintenance for reliability, safety and energy efficiency and compliance with legislation. All of these contribute to a cost-effective compressed air system.

Missing a maintenance service is a false economy, for compressors, ancillary equipment and the distribution piping connections. Effective maintenance not only saves energy it helps address the more critical issue of air supply reliability for processes. For most operations reliability of supply (whether this be pressure, volume or air purity) is paramount. Although energy efficiency receives wide coverage, reliability of supply has even greater business implications, e.g. a metal products manufacturer had paid little attention to its compressed air system, stating that it only represented 4% of the site energy costs. However if the supply failed then the cost of lost production of a number of critical processes dwarfed the energy costs, so improving the system should have been a priority and delivered energy benefits as an added bonus.

Oil-free condensates and condensates from gas compressors are normally highly aggressive. However, they cannot attack the Bekomat 13 CO PN 40. The excellent corrosion resistance of the device is due to a 50 micron hard coating, which gives a ceramic structure to the surface of its aluminium housing.

Oil-free condensates and condensates from gas compressors are normally highly aggressive. However, they cannot attack the Bekomat 13 CO PN 40. The excellent corrosion resistance of the device is due to a 50 micron hard coating, which gives a ceramic structure to the surface of its aluminium housing.

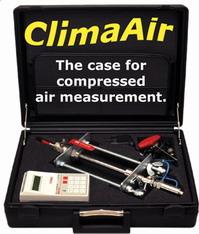

The hand-held ClimaAir Instrument is used in conjunction with the CombiSensor to calculate compressed air flow in m

The hand-held ClimaAir Instrument is used in conjunction with the CombiSensor to calculate compressed air flow in m For the first time ever, it is now possible to monitor the quality of compressed air by online measurement of the residual oil content.

For the first time ever, it is now possible to monitor the quality of compressed air by online measurement of the residual oil content. Earlier this year the university of Leeds held a training course entitled "Pharmaceutical Medical Gas Testing". This was held at the new training facility of Midland Medical Services Ltd, Rowley Regis, West Midlands. 32 delegates were in attendance for 5 days.

Earlier this year the university of Leeds held a training course entitled "Pharmaceutical Medical Gas Testing". This was held at the new training facility of Midland Medical Services Ltd, Rowley Regis, West Midlands. 32 delegates were in attendance for 5 days. Compressed-air users know the problem: the legal regulations applying to the processing of unavoidably accumulating condensate are becoming ever more strict and comprehensive. Simultaneously, the costs need to remain within economically justifiable limits. Decentralised processing of condensates directly at the point of origin has therefore established itself as the most suitable and above all, the most-effective solution. This is exactly what the new Owamat oil-water separator generation made by Beko does better than ever before.

Compressed-air users know the problem: the legal regulations applying to the processing of unavoidably accumulating condensate are becoming ever more strict and comprehensive. Simultaneously, the costs need to remain within economically justifiable limits. Decentralised processing of condensates directly at the point of origin has therefore established itself as the most suitable and above all, the most-effective solution. This is exactly what the new Owamat oil-water separator generation made by Beko does better than ever before. Compressed air that is used for medical treatments has to meet special requirements in terms of compressed air quality, availability and patient safety. With Medbac, permanent monitoring of the compressed air quality has now become reality. This makes it easy to comply with the mandatory limit values stipulated in the European Pharmacopoeia.

Compressed air that is used for medical treatments has to meet special requirements in terms of compressed air quality, availability and patient safety. With Medbac, permanent monitoring of the compressed air quality has now become reality. This makes it easy to comply with the mandatory limit values stipulated in the European Pharmacopoeia. Compressed air drying is a decisive factor for the process reliability in the production and for the operational reliability in compressed-air systems. Therefore, BEKO has offered a comprehensive program regarding compressed-air drying for many years. Amongst others, the cold-regenerated Drypoint AC adsorption dryers for volume flows up to 1500 m3/h are highly regarded. However, for some compressed-air users, this is not enough. With the heat-regenerated BEKO Everdry adsorption dryers for volume flows up to 20,000 m3/h (and more), Beko offers standardised system solutions for compressed-air drying on a grand scale.

Compressed air drying is a decisive factor for the process reliability in the production and for the operational reliability in compressed-air systems. Therefore, BEKO has offered a comprehensive program regarding compressed-air drying for many years. Amongst others, the cold-regenerated Drypoint AC adsorption dryers for volume flows up to 1500 m3/h are highly regarded. However, for some compressed-air users, this is not enough. With the heat-regenerated BEKO Everdry adsorption dryers for volume flows up to 20,000 m3/h (and more), Beko offers standardised system solutions for compressed-air drying on a grand scale. A Midlands based manufacturing company has launched a new innovative solution for industrial air compression.

A Midlands based manufacturing company has launched a new innovative solution for industrial air compression.