One of the challenges facing plant instrumentation engineers today is the effective and reliable monitoring of thrust bearing wear in critical pump applications. Typically pumps of this type are in continuous use and operational downtime is normally only permitted during planned outages. Predicting the wear and hence requirement to replace the thrust pads, is essential to fit in with this regime.

One of the challenges facing plant instrumentation engineers today is the effective and reliable monitoring of thrust bearing wear in critical pump applications. Typically pumps of this type are in continuous use and operational downtime is normally only permitted during planned outages. Predicting the wear and hence requirement to replace the thrust pads, is essential to fit in with this regime.With rotational speeds between 3000 and 7000 RPM, protection against potential pump damage is also key, as excessive thrust wear can not only damage the bearing assembly but also the impeller, resulting in the plant potentially being out of action for 6 months or more.

The company Huilerie de Tahiti in Papeete recently inaugurated its new coconut oil-fired boiler house in the presence of Oscar T

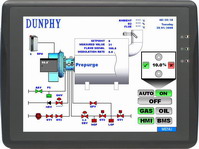

The company Huilerie de Tahiti in Papeete recently inaugurated its new coconut oil-fired boiler house in the presence of Oscar T  Dunphy has launched their new, in-house designed touchscreen for the Ratiotronic TM 6000 digital burner/boiler management system. The panel has all the functionality of a standard PC including IP addressable web access.

Dunphy has launched their new, in-house designed touchscreen for the Ratiotronic TM 6000 digital burner/boiler management system. The panel has all the functionality of a standard PC including IP addressable web access. Queensway based Dunphy Combustion Ltd has recently completed a state of the art, carbon neutral, energy installation for a major dairy and cheese making factory in Wels, Austria. Landfrisch Molkerei GmbH approached Dunphy

Queensway based Dunphy Combustion Ltd has recently completed a state of the art, carbon neutral, energy installation for a major dairy and cheese making factory in Wels, Austria. Landfrisch Molkerei GmbH approached Dunphy

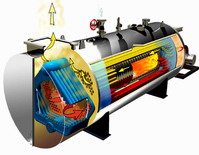

Earlier in 2007, Byworth Boilers announced the launch of their new fuel efficient steam boiler. It was claimed that the Byworth Yorkshireman2 steam boiler is the most fuel efficient boiler of its type due not only to unique XiD boiler tube, but by the quality and integrity of design and engineering. Fuel savings will vary according to the efficiency of the existing boilers, but can be between 2 and 20%.

Earlier in 2007, Byworth Boilers announced the launch of their new fuel efficient steam boiler. It was claimed that the Byworth Yorkshireman2 steam boiler is the most fuel efficient boiler of its type due not only to unique XiD boiler tube, but by the quality and integrity of design and engineering. Fuel savings will vary according to the efficiency of the existing boilers, but can be between 2 and 20%. An Indonesian garment producer has reduced its fuel consumption by a third, simply by improving the water supply to its boiler.

An Indonesian garment producer has reduced its fuel consumption by a third, simply by improving the water supply to its boiler. Annual maintenance and strip downs happen every year and planning is the key, working out when you can fit in that all-important service, is a vital part of maintaining a healthy boiler house, but can you really afford to have the downtime?

Annual maintenance and strip downs happen every year and planning is the key, working out when you can fit in that all-important service, is a vital part of maintaining a healthy boiler house, but can you really afford to have the downtime? Byworth Boilers are aware that boiler users are increasingly suffering from rising fuel bills, and with this in mind the boiler manufacturer embarked on a 2 year project in conjunction with Leeds University. The brief was, by rigorous testing, to ascertain and prove the optimum configuration of shell, furnace, and tubes for maximum boiler efficiency and low emissions.

Byworth Boilers are aware that boiler users are increasingly suffering from rising fuel bills, and with this in mind the boiler manufacturer embarked on a 2 year project in conjunction with Leeds University. The brief was, by rigorous testing, to ascertain and prove the optimum configuration of shell, furnace, and tubes for maximum boiler efficiency and low emissions.  BABCOCK WANSON is leader in the field of the design and the installation of thermal oil heaters TPC and EPC (high outputs, service contracts on demand, compliance with environmental standards).

BABCOCK WANSON is leader in the field of the design and the installation of thermal oil heaters TPC and EPC (high outputs, service contracts on demand, compliance with environmental standards).