News

Single ordering number eases procurement; field-tested design ensures performance

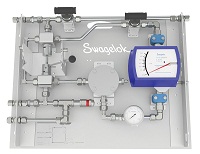

Swagelok Company recently introduced its Swagelok® Pre-Engineered Subsystems, a series of five standardized subsystems for use in all types of plants and facilities where fluids are processed. Predesigned, each subsystem features Swagelok quality engineering for maximized performance and operation, including integrated design of key safety and efficiency measures. Preassembled, each Swagelok subsystem is available as a single ordering number for improved procurement and ease of installation across a plant.

Single ordering number eases procurement; field-tested design ensures performance

Swagelok Company recently introduced its Swagelok® Pre-Engineered Subsystems, a series of five standardized subsystems for use in all types of plants and facilities where fluids are processed. Predesigned, each subsystem features Swagelok quality engineering for maximized performance and operation, including integrated design of key safety and efficiency measures. Preassembled, each Swagelok subsystem is available as a single ordering number for improved procurement and ease of installation across a plant.

Bespoke engineering solutions provider, Branch Hydraulic Systems (Branch) has built and supplied a testing unit for Compact Orbital Gears (COG), a specialist gearbox and test rig manufacturer based in Mid Wales. As part of a supply-chain-partnership, the Branch test unit is being integrated with a high-speed slave gearbox, designed and manufactured by COG, for the testing of main rotor gearboxes for a world leading helicopter manufacturer.