When Wilson Fan Pumps and Motors Group in Mitcham, South London required a large ATEX motor for a very important client who was facing a pending emergency, it placed a call through to TEC Electric Motors in Worcestershire and found the perfect solution.

Wilson Fan Pumps and Motors Group regularly works with one of the largest hospitals in London, supplying, fitting and maintaining electric equipment of all kinds. Due to the life-saving work that goes on there, Wilson’s always assigns a high importance to any contact with its engineers and estate staff and will go the extra mile when required.

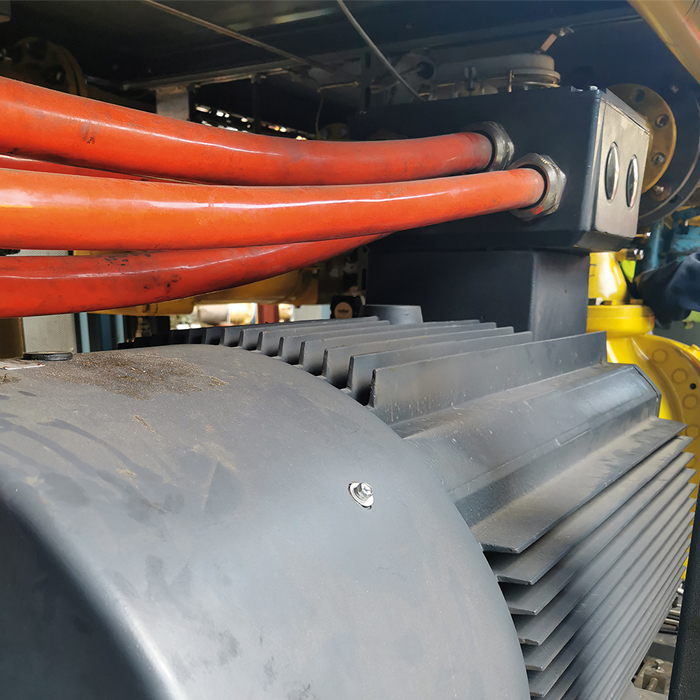

So, when the hospital called to say one of its 315 kW motors had failed and needed immediate attention, Wilson’s kicked into high gear. Hearing that the motor was installed alongside a gas turbine, the team immediately knew this was going to be an Ex rated machine, so quickly dispatched electrical engineers to investigate the problem and explore solutions. It also put a pre-emptive call through to TEC, which has the UK’s largest stock of electric motors, drives and gearboxes and therefore was most likely to have a suitable replacement motor available.

Zac Brown, Sales Manager at Wilson Fan Pumps and Motors Group, recalls: “Motors of that size are usually doing critical work. Yet they are too large for many operators to hold spares and, similarly, most stockists will not keep them on the shelf.” The first thing the Wilson engineers did was assess the motor for in-situ repairs and then quickly discounted that option, so a replacement motor had to be found. “When the news came back from site that we needed to find an ATEX Zone 2 Exn A IIC T3 machine, we knew the odds were against us.”

A quick check of the name plate identified the manufacturer, who was called, and supply options discussed. There wasn’t a suitable motor available, not even via distant distributors and manufacturing one was going to take a long time. “We were looking at a 12-week lead time, which was just not acceptable at all,” says Zac.

“We had a serious situation at the hospital, and we had to explore other avenues. Fortunately, TEC’s reputation preceded them, so we knew that there was a good chance they would have a suitable motor in their giant warehouse, plus the in-house expertise to make any modification work required in double-quick time.”

TEC did indeed have just the right motor in stock and had the experience to know the right questions to ask about the installation to make sure it could be dispatched on a right-first-time basis. The motor required some minor modifications, which the TEC technicians started work on straight away. Meanwhile, Wilson’s team was organising the specialist lifting gear and scaffolding required to remove the failed motor and ensuring that everything was ready for the delivery from TEC.

The hospital, Wilson Fan Pumps and Motors Group and TEC made sure there were engineers on-hand when the motor arrived on site, ready to install, laser-align, test and commission it straight away. The objective was to do the job quickly and efficiently so that it was available to carry out its critical duties reliably for many years to come.

Gareth Richardson, Sales Director at TEC Motors, concluded: “This is an example of our ability to respond at short notice to meet customers’ challenging objectives. We are a service-led company that reacts quickly and efficiently to customers’ needs.”

For more information visit: https://tecmotors.co.uk/