For manufacturers of equipment intended for explosive atmospheres, technical documentation is not a formality it is foundational to ATEX and IECEx certification. Certification bodies primarily assess conformity through the documented evidence provided. If that evidence is unclear, incomplete, or inconsistent, even well-designed equipment may face delays, redesign, or rejection.

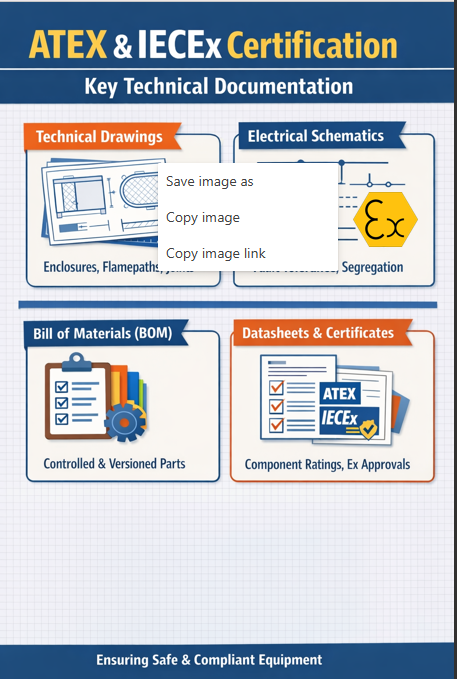

Drawings and Schematics Define Safety General arrangement and assembly drawings define how the equipment is built. These include details such as enclosure construction, joint types, fasteners, sealing methods, and clearances—all vital to verifying the chosen protection concept (e.g. Ex d, Ex e, Ex i, Ex p, or Ex t). Certification assessors use these drawings to confirm that the protection concept has been applied correctly and consistently. Gaps in documentation inevitably trigger technical queries.

Electrical schematics are equally important. They provide visibility into circuit topology, protection devices, segregation of circuits, and interfaces between hazardous and safe areas. In methods like intrinsic safety or increased safety, the schematic is central to assessing energy limitation, fault tolerance, and standard compliance. Poorly structured schematics are a common source of late-stage non-compliances.

BOMs and Datasheets Build Confidence A clear, version-controlled Bill of Materials (BOM) links the assessed design to what is manufactured. It is essential for demonstrating configuration control, ensuring that each production unit matches the certified design. A generic or uncontrolled BOM undermines the credibility of the entire assessment.

Equally, datasheets for critical components—such as relays, batteries, transformers, and cable glands—are indispensable. These documents provide the rated electrical, thermal, and mechanical limits that underpin compliance. Often, the validity of a protection concept hinges on specific component performance. Missing or ambiguous datasheets can halt the certification process entirely.

Component-level ATEX or IECEx certificates (e.g. for glands, enclosures, barriers) are also vital. They allow the assessor to rely on third-party evaluations rather than re-assessing internal construction. Their absence can force deeper, more time-consuming evaluations at the equipment level.

Better Documentation, Faster Certification High-quality documentation reduces lead times, avoids unnecessary technical queries, and supports ongoing quality assurance, change control, and audit readiness. For manufacturers, investing in documentation early in the development process leads to smoother, more predictable certification outcomes—and ultimately safer, more reliable products in the field.

Artilcle by Anoop Chandrahasan, ExVeritas Operations Manager