Wolf Safety, the world’s leading manufacturer of hazardous area portable and temporary lighting, launches an extensive range of positioning, mounting and protection accessories, encompassing fixing kits, films and cable management, for its ATEX and IECEx approved LinkEx™ LED Temporary Luminaire (LX-400), giving workers more secure temporary installation solutions for lighting in hazardous area working environments.

Wolf Safety, the world’s leading manufacturer of hazardous area portable and temporary lighting, launches an extensive range of positioning, mounting and protection accessories, encompassing fixing kits, films and cable management, for its ATEX and IECEx approved LinkEx™ LED Temporary Luminaire (LX-400), giving workers more secure temporary installation solutions for lighting in hazardous area working environments.

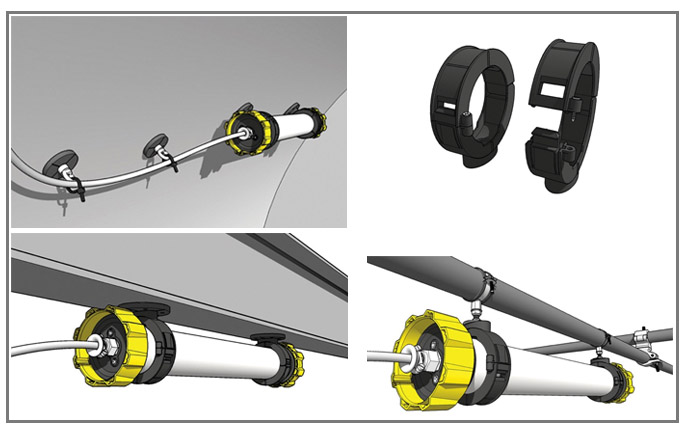

Wolf’s LinkEx™ LED Temporary Luminaire plastic brackets, with snap shut mechanism and screw to lock securely closed around a luminaire, form a key component of all Wolf’s fixing kits giving flexible and sturdy mounting and positioning options for temporary applications. Securely mount or hang a luminaire almost anywhere and in any orientation - with brackets and screws fix directly to flat walls, with magnet pads grip to flat ferrous metal surfaces, with scaffold clamps fit to standard poles 47 to 51 mm diameter, with unistrut nuts attach to standard channel systems, with eye bolts suspend with carabiners and S hooks, or simply hang with hanging straps from existing infrastructure - putting the luminaire exactly where it is needed.

For standalone luminaire positioning, Wolf's tripods give a stable platform allowing the luminaire to be attached with mounting brackets and used at a variety of heights and positions to deliver vertical or horizontal forward facing light, in the horizontal position the light can be directed upwards, illuminating the work area from the underside. The range of tripods available are lightweight, easily transportable, made from steel and will extend a lamp to a height of up to 3.2 meters and are ideal for both '180°' (unidirectional illumination) and '360°' (omni-directional 'all round' illumination) luminaires to maximise light area coverage for workers.

Alex Jackson, Wolf Safety Managing Director comments "Putting light where it is needed increases the productivity of workers by giving them control in positioning and selecting the required light level for optimal comfort and safety - our range offers extensive choice and flexible options. All accessories are designed for simple and quick installation and removal to minimise set-up time when working within a confined space environment, like our temporary lighting all are built to be durable offering maximum safety and longevity when used repeatedly in demanding hazardous area conditions."

Not only is the positioning and mounting of luminaires key to worker efficiency but also the protection of equipment to ensure its longevity, in optimal condition, for repeat usage. Wolf luminaires are used regularly in blasting, jetting, coating and painting applications and are protected from residue build-up by the use of protective films, easily replaced between uses to ensure the product is delivering maximum light output without obstructions. Similarly if the luminaire is deemed too bright, when being used in a confined space at head height by a worker, an internal diffuser film can be installed to minimise glare. Finally, to keep the working area free from potential trip hazards, cable can be managed using a magnet cable tidy to elevate it from the ground along a ferrous metal surface.

Alex Jackson adds "If end users require accessories to suit particular hazardous area needs, whether a variation to our existing range or a totally new accessory for a unique application and environment, we will work together to develop a practical and safe solution."

For further information on the LX-400 Accessories please visit our http://www.wolf-safety.co.uk/accessories/lx-400-accessories.

Wolf Safety Lamp Company Limited

T: +44 (0)114 255 1051

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

W: www.wolf-safety.co.uk