Two new apps could help prepare the next generation of process safety engineers for the field. An app developed by the University of Surrey allows users to control a simulated plant environment while another app, made by the University of California, Riverside, finds the safest way to store and dispose of reactive chemicals.

The University of Surrey’s app enables students and engineers to benefit from its Fluor Pilot Plant, a learning space within the Department of Chemical and Process Engineering which gives students access to state-of-the-art equipment that replicates what they will eventually use in industry. The facility is a fully operational chemical process plant that demonstrates all of the main functions of an industrial plant: chemical reaction, solids handling, filtration, heat exchange and CO2 capture by gas absorption. It utilises a safe whole process to produce very pure saline solution from a contaminated salt feed.

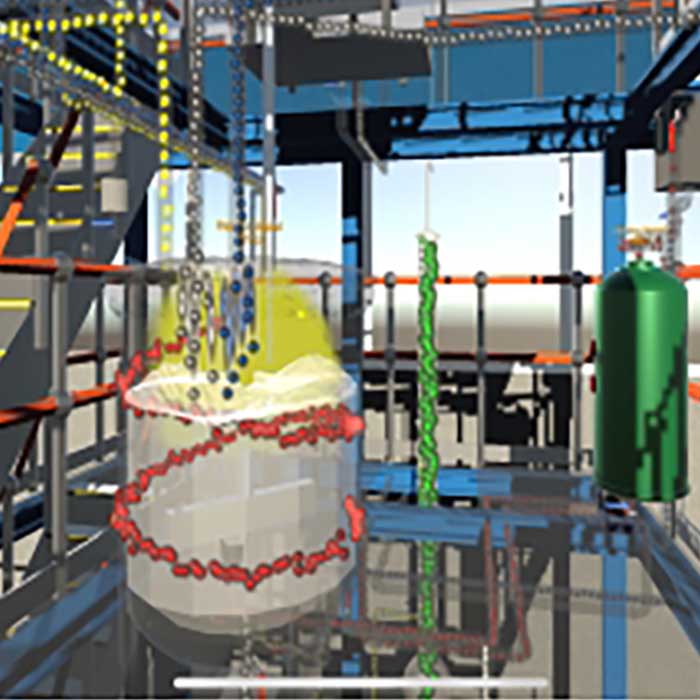

The new app allows users to learn about the whole chemical engineering process by operating a digital replica of the real Fluor Pilot Plant. On the app, users can operate equipment such as the main reactor, filter and feed hopper, making decisions like controlling flow rates, with an alarm alerting them if they do something wrong.

The app was developed by Professor Sai Gu’s team in the Department of Chemical and Process Engineering, and is available for free in the Google and Apple app stores. It is designed to be used by university students at Surrey and around the world as well as working engineers and school students. At present Surrey is one of the few universities in the UK to offer a fully operational pilot plant facility, so the aim is to share this unique experience with a wider range of trainee engineers.

In addition, the app will be offered to the training programmes run by the Department including the flagship annual OPCW (Organisation for the Prohibition of Chemical Weapons) Associate Programme which sees representatives from countries around the world come to Surrey to learn about chemical industry standards and safety procedures. Using the app will enable delegates to familiarise themselves with the plant in advance of the programme.

Building on the new Fluor Pilot Plant app, Professor Sai Gu’s team is also designing a video game based on the pilot plant. To download the app, search ‘CPE Digital Chemical Plant University of Surrey’ at the Google Play Store, or ‘CPE Digital Chemical Plant UoS’ at the Apple App Store.

Another app, currently under development, is an open source computer program called ChemStor developed by engineers at the University of California, Riverside. The technology can prevent these dangerous situations by telling users if it is unsafe to mix certain chemicals.

Improperly mixed chemicals cause several fires, explosions, and injuries in businesses and homes, but even in laboratories and factories where workers are trained in safe storage protocols, mix-ups and accidents happen, often after chemicals are inadvertently combined in a waste container.

The UC Riverside engineers’ work is published in the Journal of Chemical Information and Modeling. Their program adapts a computer science strategy to allocate resources for efficient processor use, known as graph colouring register allocation. In this system, resources are coloured and organised according to a rule that states adjacent data points, or nodes, sharing an edge cannot also share a colour.

ChemStor draws from an Environmental Protection Agency library of 9,800 chemicals, organised into reactivity groups. It then builds a chemical interaction graph based on the reactivity groups and computes the smallest number of colours that will colour the graph such that no two chemicals that can interact also share the same colour.

ChemStor next assigns all the chemicals of each colour to a storage or waste container after confirming there is enough space. Chemicals with the same colour can be stored together without a dangerous reaction, while chemicals with different colours cannot.

If two or more chemicals can be combined in the same cabinet or added to a waste container without forming possibly dangerous combinations of chemicals, ChemStor determines the configuration is safe. ChemStor also indicates if no safe storage or disposal configuration can be found. ChemStor’s functionality is currently limited to a command line interface only, where the user manually enters the type of chemicals and amount of storage space into a computer.

Updates are forthcoming to make ChemStor more user-friendly, including a smartphone app utilising the camera to gather information about chemicals and storage options, as well as an integration with digital voice assistants, some of which have already begun to be developed specifically for chemists, making ChemStor a natural addition.