Bionic Fuels are small / medium size commercial biodiesel producer based in East Sussex, UK. The company has been involved in testing and assisting in the development of a biodiesel specific field test kit designed to give key data throughout the production cycle.

Bionic Fuels are small / medium size commercial biodiesel producer based in East Sussex, UK. The company has been involved in testing and assisting in the development of a biodiesel specific field test kit designed to give key data throughout the production cycle.

Biodiesel production, despite being a fairly simple chemical reaction, encompasses many variables that can affect finished product quality. There is a recognised European standard (EN14214), however, the full suite of tests can be costly and the regularity with which these tests may be required can prove cost negative for the smaller producer. That said, sub standard fuel producers have in the past caused the fledgling industry to attract a bad name in some areas.

Most commercial producers now realise that in order to compete in the important fleet sector,quality is not only a key buying motivator but a prerequisite to opening discussions. The problem then, is to identify and manage the variables in batches between regular laboratory tests.

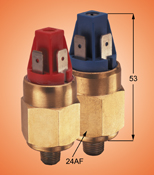

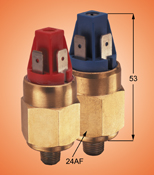

This PMN pressure switch is the original and still the best with many thousands in use by OEM's worldwide. Prices start at just

This PMN pressure switch is the original and still the best with many thousands in use by OEM's worldwide. Prices start at just  This PMN pressure switch is the original and still the best with many thousands in use by OEM's worldwide. Prices start at just

This PMN pressure switch is the original and still the best with many thousands in use by OEM's worldwide. Prices start at just

The new belt tension tester from Econobelt uses sound waves instead of force deflection to accurately measure tension. The portable, lightweight and easy-to-use meter produces repeatable results for any operator. It can be used in almost any environment and produce fast results, calculated in seconds. The unit, identified as the 507C runs on four AAA batteries.

The new belt tension tester from Econobelt uses sound waves instead of force deflection to accurately measure tension. The portable, lightweight and easy-to-use meter produces repeatable results for any operator. It can be used in almost any environment and produce fast results, calculated in seconds. The unit, identified as the 507C runs on four AAA batteries. The COMBI 75 combines dry ice pellet production and dry ice blasting

The COMBI 75 combines dry ice pellet production and dry ice blasting I have received many calls asking, "How can you tell if an organization is a world class reliability and maintenance organization or not?"

I have received many calls asking, "How can you tell if an organization is a world class reliability and maintenance organization or not?" Bionic Fuels are small / medium size commercial biodiesel producer based in East Sussex, UK. The company has been involved in testing and assisting in the development of a biodiesel specific field test kit designed to give key data throughout the production cycle.

Bionic Fuels are small / medium size commercial biodiesel producer based in East Sussex, UK. The company has been involved in testing and assisting in the development of a biodiesel specific field test kit designed to give key data throughout the production cycle. Trader Media Print division is part of the Guardian Media Group and produce well-known magazine publications such asAutoTrader. These publications are dated and therefore must be on the shelves at an exact time or the business loses revenue. Managing Director, Alan Turner came to EMS recognising that they were lagging behind in manufacturing practice.

Trader Media Print division is part of the Guardian Media Group and produce well-known magazine publications such asAutoTrader. These publications are dated and therefore must be on the shelves at an exact time or the business loses revenue. Managing Director, Alan Turner came to EMS recognising that they were lagging behind in manufacturing practice. Calibration is an essential element of any instrumentation maintenance program. However, calibration operations can be long and time-consuming. By using the Beamex

Calibration is an essential element of any instrumentation maintenance program. However, calibration operations can be long and time-consuming. By using the Beamex Article written by Christer Idhammar President, IDCON, Inc., a maintenance management consulting and training company.Further information is available by contacting

Article written by Christer Idhammar President, IDCON, Inc., a maintenance management consulting and training company.Further information is available by contacting  By Frank Mowka

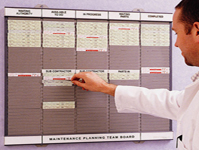

By Frank Mowka Philip Heine from T Cards Direct explains why many companies go for a simple approach to coordinating Engineering Staff and Health & Safety

Philip Heine from T Cards Direct explains why many companies go for a simple approach to coordinating Engineering Staff and Health & Safety