There has been considerable growth in the wind power industry over the past few years. However, further exponential growth of the industry is required in order to ensure that the net-zero by 2050 pathway (outlined in the Paris Agreement) is successfully reached.

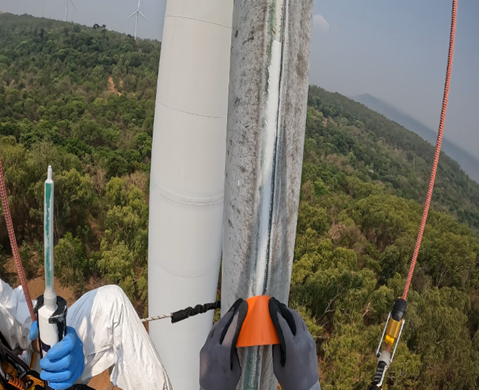

Figure 1 - Maintaining the integrity of wind turbines with polymeric technology

In order to support this seismic growth, polymeric repair and protection technology has an important part to play. Designed to safeguard the integrity of wind turbine blade leading edges for the long term, this technology plays a critical role in supporting this burgeoning industry.

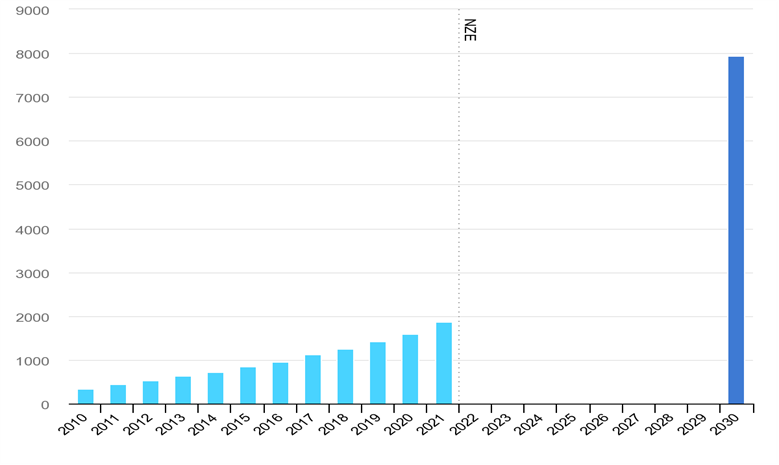

Wind Electricity Generation Needs to Grow Fourfold by 2030

According to the International Energy Association’s (IEA) Wind Electricity Tracking Report

(September 2022): “In 2021 wind electricity generation increased by a record 273 TWh (up 17%). This was 55% higher growth than that achieved in 2020 and was the highest among all renewable power technologies.”

While the industry has undoubtedly experienced impressive levels of growth in these years, according to the IEA, wind electricity generation needs to reach four times the record levels set in 2020 by 2030. The Report said: “Our pathway calls for scaling up solar and wind rapidly this decade, reaching annual additions of […] 390 GW of wind by 2030”.

Figure 2- Wind electricity generation needs to grow fourfold by 2030 (IEA. License: CC BY 4.0)

How is the Scale-Up of the Wind Industry Being Financed?

According to the IEA’s Report: “Policy support remains the principal driver of wind deployment in the majority of the world.” Indeed, over the past few years, several policies have been launched that are designed to drive forward the roll-out of renewables.

For example, in August 2022, the US brought in the Inflation Reduction Act (IRA) which includes $369 billion (US dollars) of investment, in the European Commission’s Green Deal Industrial Plan, $270 billion (US dollars) was pledged, and since the UK government’s Ten Point Plan was launched in November 2020, over £26 billion of government capital investment has been mobilised.

Safeguarding Expanding Fleets of Wind Turbines with Polymeric Technology

Given the critical role wind power plays in the transition to a net-zero future, as well as the significant amount of capital being invested into the renewables industry, the wind power sector is poised to experience considerable exponential growth in the upcoming decades. In order to support this growth, polymeric technology plays a significant role when it comes to maintaining the operational efficiency of the rapidly expanding fleets of wind turbines.

Polymeric systems such as the rebuild, blade filler material, Belzona 5711 and the cartridge-applied leading edge protection coating, Belzona 5721, are specially designed to repair damaged leading edges and protect them against rain erosion and impact damage for the long term.

In addition to the performance capabilities of these systems, maintenance engineers are investing in this technology due to the simple, in-situ application method and fast cure times the cold-curing systems facilitate. In turn, this helps to keep downtime to a minimum, and allows the turbine to be returned to service in the same day.

Belzona 5711 can be directly overcoated with Belzona 5721 in as little as 30 minutes at 20°C/68°F without the need for any additional surface preparation. At the same temperature, Belzona 5721 will be fully cured within five hours.

Below is a case study featuring the repair and protection of a wind turbine leading edge with Belzona 5711 and Belzona 5721.

Wind Turbine Blade Repaired and Protected

Belzona, a global designer and manufacturer of industrial protective coatings and repair composites, successfully addressed the wind turbine blade damage issue at Electricity Generating Authority of Thailand’s (EGAT) Khao Yai Thiang Windfarm in Thailand.

Figure 3 - Leading edge damaged by erosion

Leading Edge Erosion Damage

The windfarm features wind turbines with 40-metre-long (131.2 ft) blades. During routine inspections, evidence of damage measuring 300 cm x 14 cm x 2 mm (118 in x 5 in x 0.08 in) on the leading edge of one of the blades was discovered.

System Selection

Representatives from the 35-year-old Belzona Authorised Distributorship, Pan Mechanic Engineering, recommended the solvent-free, two-part repair paste, Belzona 5711, to reconstruct the damaged area on the blades, followed by the high-performance coating, Belzona 5721, to overcoat the area.

Application Procedure

The application procedure involved surface preparation using an orbital sander, followed by the direct application of approximately 1.4 kg (3.1 lbs) of Belzona 5711 from a self-mixing cartridge onto the blade. The repair area was contoured using a piece of Belzona mixing board.

Figure 4 - Surface preparation using an orbital sander

Figure 5 - Self-mixing Belzona 5711 cartridge

After a two-hour curing period, a visual inspection was conducted to ensure the application's readiness for overcoating with approximately 3.5 kg (7.7 lbs) of Belzona 5721. Using a short-bristled brush, this system was then applied to the leading edge and left to cure. The blade was back in service 24 hours later.

Figure 6 – Application of repair paste, Belzona 5711

Figure 7 – Application of high-performance coating, Belzona 5721

EGAT's technicians were trained at the Belzona Asia Pacific facility to perform the application, with two representatives from Belzona's Technical Service Department present on site to observe and provide guidance.

Figure 8 – Completed repair and protection of leading edge

Figure 9 – Successful application of Belzona polymeric systems

Commenting on the application, an EGAT representative said: "We are extremely satisfied with

the results achieved by Belzona's leading edge repair and protection system. The application procedure was very simple, and could be carried out quickly, which ensured that downtime was kept to a minimum. We plan to place an order for more Belzona 5711 and Belzona 5721 .”

Supporting a Net-Zero Future

In order to support the seismic growth of the wind power sector, polymeric technology, such as Belzona 5711 and Belzona 5721, plays a critical role. By safeguarding the integrity of wind turbine blades, this helps to keep windfarms functioning at their optimum efficiency, which in turn, supports a net-zero by 2050 pathway for the planet.

More information about Belzona’s solutions for the wind industry can be found at: http://www.belzona.com/en/industries/wind_power.aspx