Static Earthing Protection for Vacuum Tankers

Static Earthing Protection for Vacuum Tankers

Vacuum tankers provide a wide range of services to the hazardous process industries, ranging from storage tank cleaning to the recovery of combustible materials resulting from leaks and spills. A key feature of this type of service is the recovery of materials in locations with potentially combustible atmospheres.

Static electricity is a well-known ignition source within the hazardous process industries and because the (Read More)

generation and accumulation of static is not visible to the naked eye, this “below the radar” characteristic makes it an exceptionally precarious and dangerous hazard. Normally, the only evidence of static electricity being present during a transfer operation is when somebody sees or hears a static spark discharge. By then it may be too late to prevent the ignition of the surrounding atmosphere if it’s in combustible range.

Earthing vacuum tankers operating in hazardous areas eliminates the threat posed by static electricity and is an action that effectively connects the tanker to the general mass of the Earth, sometimes called “True earth”. The voltage induced on the tanker by the charged material is the key factor in a static spark discharge. Earthing ensures that no voltages are generated and permitted to accumulate on the tanker.

Even though the potential and consequences of fires is, at the very least, the same for road tankers at dedicated loading gantries, vacuum tanker service providers have not been in a position to provide this level of safety and protection of their personnel and tankers, or for their customers’ personnel and property.

Until now, vacuum tanker service providers have had to rely on very basic devices to earth their vehicles. This is simply because technology that is capable of verifying the quality of static earthing points in a mobile, quick and user-friendly way has not been available to drivers and operators. The method currently used consists of a simple earthing clamp attached to single core braided cable wound onto a reel.

Very often, vacuuming operations will be carried out on facilities and remote locations where “designated” earthing points may not be tested on a regular basis, are not accessible or do not exist.

Bulk transportation companies can also have the same difficulties when they deliver product to customer sites where earthing systems are not up to current specifications, or worse still, are not installed.

When compared to the performance and safety of static earth monitoring systems, single core bonding reels have several major drawbacks. These include not having the capability to notify the driver whether or not the clamp has penetrated rust, paint or other potential resistors to the flow of static electricity, nor if the clamp’s connection has become compromised during the transfer.

Unlike the security provided to road tanker drivers and loading gantry operators by gantry mounted earth monitoring systems, the vacuum tanker team running a recovery or transfer operation has no way of knowing if their tanker is connected to a good earth.

Contract service providers, and customers, have concerns due to such limitations because the teams are connecting reels to earthing points that have neither been tested nor verified as being connected to a True earth ground.

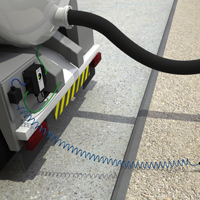

In order to remove this uncertainty and provide vacuum tanker service providers with the same level of protection that gantry mounted static earth monitoring systems provide, Newson Gale developed a Mobile Grounding Verification system - the Earth-Rite® MGV.

The Earth-Rite MGV is a vehicle mounted solution and is a permanent component of the tanker, giving providers and customers the same level of safety and performance that a gantry mounted static earthing system can provide.

The MGV incorporates the recommendations of API RP 2219 “Safe Operation of Vacuum Trucks in Petroleum Service”, which is the most relevant standard to address the precautions that should be put in place when vacuum tankers are being used to transfer combustible materials or are carrying out transfers in potentially combustible atmospheres.

Focussing on the first requirement of the standard, it states that we need to establish that the earthing point we are connecting the tanker to, is a proven “ground source”. The ground source, in other words, is an object that has a direct electrical connection to a True earth ground. The MGV system matches this requirement by ensuring the earthing point to which it is connected has a verifiable connection to True earth. This function is called “Static Ground Verification” (SGV).

To ensure the connection between the point the MGV has verified as having a connection to a True earth ground and the tanker is 10 ohms or less, the MGV will continuously monitor the tanker’s connection to the now verified earthing point. In addition, the MGV monitors its own connection to the tanker. This is especially important as it ensures both the tank and chassis are connected to earth via the MGV system. This ensures that there is a continuously monitored circuit between the tanker and the verified earthing point which will enable static electricity flow off the tanker and into the ground. Because the MGV is now monitoring the circuit between the tanker and the verified earthing point, if the clamp’s connection to the earthing point is compromised or removed while a transfer is underway, the MGV system detects this. This function is called “Continuous Ground Loop Monitoring” (CGLM).

Both the SGV and CGLM checks of the Earth-Rite® MGV must be positive in order for a static ground connection to be established. When both checks are positive three highly luminous green LEDs pulse to inform the drivers that the tanker is earthed. At this point, the transfer team can proceed with the next stage of the material transfer operation. Any static generated by the transfer process will immediately flow directly through the MGV to earth, removing the risk of ignition of combustible atmospheres or shocks to operators caused by discharges of static electricity.

The green pulsing LEDs inform the team that the MGV is continuously monitoring the health of their tanker’s static earthing circuit, and will light up red if not.

For more on the Earth-Rite® MGV, visit:

www.newson-gale.co.uk