As the inventor of flameless explosion venting, REMBE is once again challenging the status quo with the new Q-Box R3leaf, the world's first sustainable device for flameless explosion venting.

After years of systematic development, testing and successful approval tests, REMBE is convinced that it has contributed to more than just an improvement in flameless explosion venting technology. Instead, the aim is to set a good example and send a clear signal that everyone can reduce the carbon footprint in our industry.

Fig. 1: The Q-Box R3leaf as the first sustainable flameless explosion venting device

During development of the Q-Box R3leaf the focus was on sustainability and the central question: Where can the status quo be further challenged?

The development of the Q-Box R3leaf expands REMBE's line of flameless explosion venting devices with a product optimised in terms of both effectiveness and sustainability.

Thanks to the selection of materials, the geometry of components and appropriate joining processes, it was possible to significantly increase the packaging density, avoid the need for emission-intensive joining and coating processes, and at the same time significantly improve the effectiveness of internal and international logistics processes. These optimisations affect the entire supply chain of the Q-Box R3leaf and thus ensure reduced CO2 emissions.

Thanks to continuous development, it was possible to significantly increase the venting efficiency of the Q-Box R3leaf, allowing plant operators to reduce the number of flameless explosion venting devices required on their plant.

How does an explosion occur?

The topic of “explosion protection” is omnipresent for plant operators and machine manufacturers when it comes to handling or transporting flammable and explosive dusts. Contrary to the widespread assumption, the risk of explosion extends beyond gases, as flammable dusts can release enormous forces.

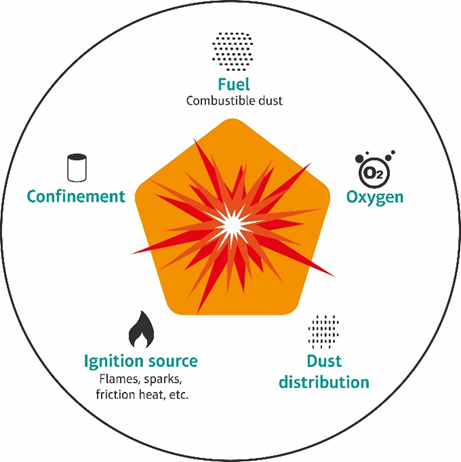

The following conditions, also known as fire triangle or dust explosion pentagon, must exist for an explosion to occur within a production facility or machine:

Fig. 2: Dust explosion pentagon

If any of the aforementioned conditions are eliminated, explosion protection has essentially been practised. However, if this is not possible at all times and in all operating states, explosion hazards persist. This necessitates categorizing explosion-prone areas into zones and systematically installing protective measures accordingly.

What is flameless explosion venting?

Flameless explosion venting devices are primarily used to protect vessels or plants against the main effects of explosions, flames and pressure, which would be released unhindered into the environment if conventional explosion venting was used. To put it simply, they consist of two elements: the explosion venting device, such as an explosion vent and a downstream flame extinguishing element. This decreases the explosive pressure to a level that is harmless for the protected plant, and at the same time reduces the temperature of the combustion gases to a harmless level.

Flameless explosion venting devices are used wherever safe pressure relief in the event of an explosion is not permitted due to the potential proximity to people, other plants or objects.