Why Monitor?

Why Monitor?The concept of Predictive Maintenance has now become accepted practice, world wide.

Locating, defining and acting on potential problems before they become catastrophic is the main objective of a predictive maintenance programme. Techniques include thermography, vibration analysis and motor monitoring. Routine monitoring is not only the most effective method of determining an early diagnosis, but has many other positive aspects.

Remove moisture and particles before entry to the system.Moisture and particle accumulation are major factors of oil contamination in industrial equipment. Neglected, these detriments restrict equipment efficiency, causing machine downtime and significant expense in replacement oil, parts and repair labour. Des-Case hygroscopic breathers incorporate a proven, field tested design.

Remove moisture and particles before entry to the system.Moisture and particle accumulation are major factors of oil contamination in industrial equipment. Neglected, these detriments restrict equipment efficiency, causing machine downtime and significant expense in replacement oil, parts and repair labour. Des-Case hygroscopic breathers incorporate a proven, field tested design. Dorchester based, Tritex NDT have developed a new range of triple echo ultrasonic thickness gauges for measuring metal thickness to check for corrosion on pipelines, storage tanks and other industrial applications where corrosion occurs. The new Tritex Multigauges have been designed for robustness, simplicity of use and most importantly, accuracy.

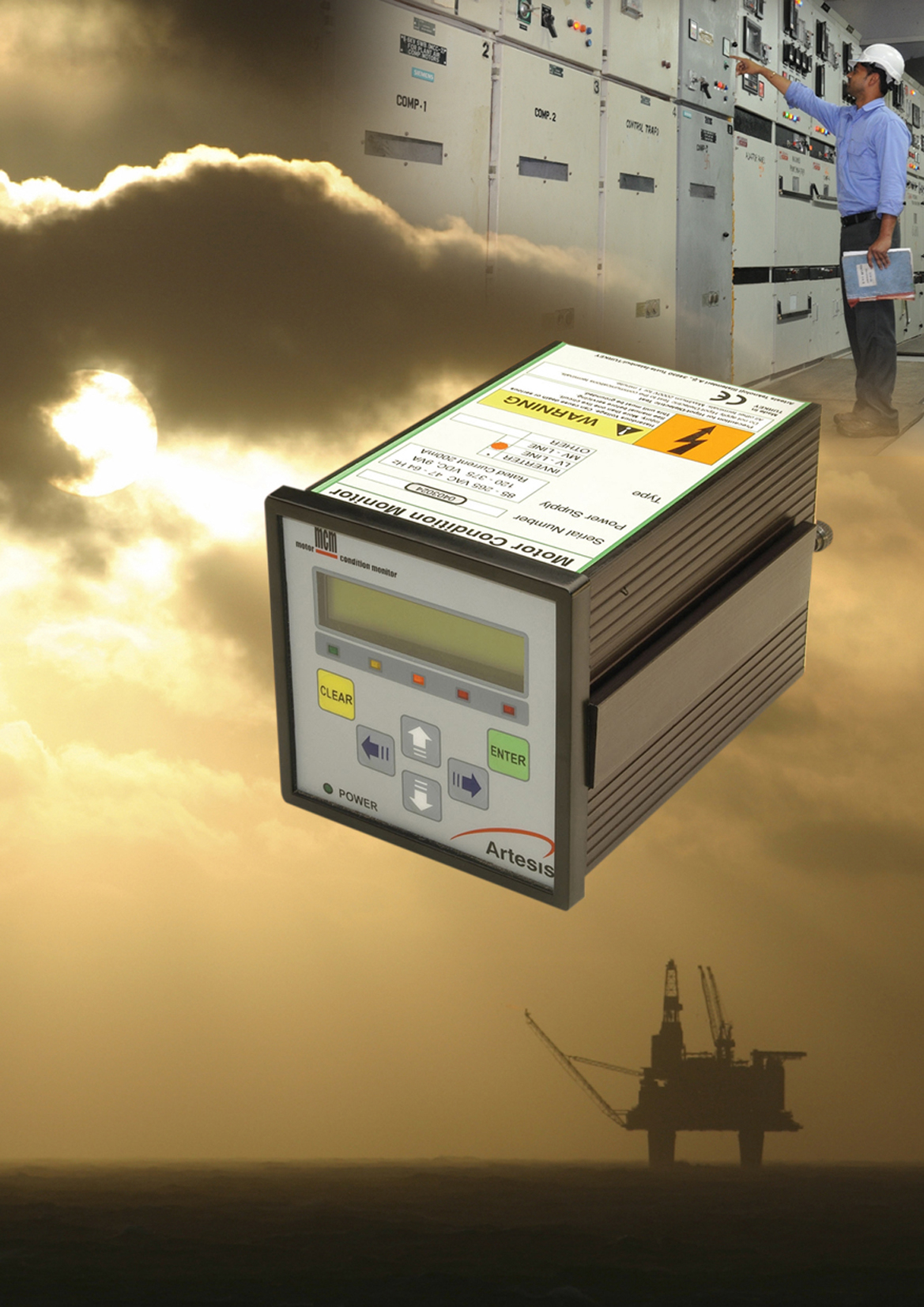

Dorchester based, Tritex NDT have developed a new range of triple echo ultrasonic thickness gauges for measuring metal thickness to check for corrosion on pipelines, storage tanks and other industrial applications where corrosion occurs. The new Tritex Multigauges have been designed for robustness, simplicity of use and most importantly, accuracy.  Artesis, a leading supplier of intelligent predictive maintenance solutions, is pushing the boundaries of machine monitoring technology with its next generation solution. Delivering a range of powerful new functionality the Artesis MCM (Motor Condition Monitor) system now includes wireless technology for deployment in remote and inaccessible locations; fully automated condition assessment reports for even faster diagnostics; and the ability for engineers to easily and quickly customise the application for wider enterprise use.

Artesis, a leading supplier of intelligent predictive maintenance solutions, is pushing the boundaries of machine monitoring technology with its next generation solution. Delivering a range of powerful new functionality the Artesis MCM (Motor Condition Monitor) system now includes wireless technology for deployment in remote and inaccessible locations; fully automated condition assessment reports for even faster diagnostics; and the ability for engineers to easily and quickly customise the application for wider enterprise use. In about 50% of organizations spare parts and materials stores reports to the maintenance organization. In about 50 % of organizations spare parts and materials stores is part of the purchasing function.

In about 50% of organizations spare parts and materials stores reports to the maintenance organization. In about 50 % of organizations spare parts and materials stores is part of the purchasing function. Hansford Sensors Ltd. now offer a range of submersible vibration sensors, which has been specifically designed for operation in partial or complete immersion in water, making them ideal for the monitoring of pumps in a maintenance role.

Hansford Sensors Ltd. now offer a range of submersible vibration sensors, which has been specifically designed for operation in partial or complete immersion in water, making them ideal for the monitoring of pumps in a maintenance role. The Easy-Laser® D160 detector unit can also be connected to our standard D279 display unit (used for shaft alignment) for full documentation.

The Easy-Laser® D160 detector unit can also be connected to our standard D279 display unit (used for shaft alignment) for full documentation. Artesis, a leading supplier of intelligent predictive maintenance solutions, has launched the MCM System on a Card (SoC), a product for the OEM sector, bringing a highly efficient and easy to use tool suite that allows the fast and complete integration of Artesis

Artesis, a leading supplier of intelligent predictive maintenance solutions, has launched the MCM System on a Card (SoC), a product for the OEM sector, bringing a highly efficient and easy to use tool suite that allows the fast and complete integration of Artesis