More than ever, businesses and the general public want the same thing

More than ever, businesses and the general public want the same thing

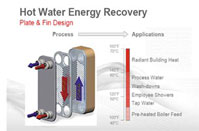

By exchanging the heat of compression in a water/coolant heat exchanger, the heat of compression can be re-used for other processes. This Energy Recovery System (ERS) is modulated with a simple temperature bypass valve.

The heated water can be used for domestic applications like central heating, showers, water sinks or industrial applications such as pre-feed to boilers or industrial cleaning process. ERS can either be supplied mounted within the compressor enclosure or as a field fitted kit.

Coolant-to-water heat exchanger common system design choice.

Why Ingersoll Rand ERS?

- Potential Annual Savings

Maximum efficiency

– Superior heat transfer

– Closer approach temperature

– No additional energy losses from compressor

– Maximum energy recovery

Simple design

– Minimal wear and tear

– Maximum reliability

– Minimal maintenance costs

More recent ingersoll news:

{mosimage}Ingersoll Rand Compressors Certified ISO 8573.1 Class 0

Ingersoll Rand is the first manufacturer in the world to receive ISO 8573.1 Class 0 certification for both oil-free air compressors ranges, centrifugal and rotary screw.

Ingersoll Rand is the first manufacturer in the world to be certified Class 0 for both centrifugal and rotary screw oil-free air compressors. The type-test certifications were granted to the entire range of Ingersoll Rand air-cooled and water-cooled oil-free rotary screw Sierra and Nirvana compressors (37 to 350kW) and Centac oil-free centrifugal aircompressors (160 to 5000 kW) by TÜV Rheinland®, an independent testing and assessment agency.

The most stringent of all ISO 8573.1 classifications, Class 0 certification was added in 2001 in response to critical applications where air purity is essential, such as the pharmaceutical, food and beverage, electronics and textiles industries. The most stringent full-flow testing methods required by the ISO 8573 standard ,for the measurement of the total oil content, were applied by TŰV.

The certification recognizes compressors that discharge air free of added oil aerosols, vapours and liquids. “The achievement of the Class 0 certification is a tangible demonstration of our commitment in developing and providing best-in-class equipments providing our customers with lower operating costs, improved productivity, risk avoidance and environmental care” said Alessandro Bulfon, President, Ingersoll Rand Industrial Technologies, European Served Area.

With maintenance expenses comprising a significant percent of lifecycle cost, Ingersoll Rand oilfree centrifugal and rotary screw air compressors enable plants to better manage operating costs, minimizing the need for coolant oil, inline filters and oil/air separator components. By eliminating the risk of compressor-created contaminants, air system components last longer and ensure higher air and product quality.

Ingersoll Rand oil-free technology also helps companies avoid risk. Oilcontaminated air can spoil and ruin products, creating significant losses of revenue and customer trust. High-quality

air reduces liability and the potential of product recalls.

Ingersoll Rand oil-free rotary screw and centrifugal air compressors also help manufacturers comply with environmental standards such as ISO 14001. Because the compressors are oil-free, manufacturers do not encounter disposal issues with waste oil and filtration components. Disposal of air compressor condensation can also be an issue in lubricated compressors. By creating a clean condensate that is easier to dispose, oil-free compressors don’t require special treatment for oil and water mixtures.

In 1912 Ingersoll Rand manufactured its first oil-free compressor and has continued to inspire progress through state-of-the-art technology and talented people. Ingersoll Rand is a global leader in oil-free compressed air technology. Their products include the class-leading Nirvana Oil-free true variable speed compressor as well as CENTAC centrifugal compressors up to 5000 kW.

www.air.ingersollrand.com

Ingersoll Rand Industrial Technologies

+44 (0)1942 503133

+44 (0)1942 503130

This email address is being protected from spambots. You need JavaScript enabled to view it.