Compair News United Kingdom >>

The Requirements for ATEX/UKCA

One of the most misunderstood aspects of ATEX and UKCA Ex Certification is the ‘blend’ of Self Certification and Notified/Approved Body Certification. There are many routes to certification, and this is explained in legislative documents, but for end users and manufacturers it can be very confusing. An example of the routes to conformity is shown below….

So what exactly does this mean?

- Electrical equipment that is CAT 1 and CAT 2 (normally for use in in Zone 0 or 1) requires Notified Body Certification for the EU and UK Approved Body Certification for the UK (no self-certification is allowed unless the equipment is Simple Apparatus*)

- Non-electrical equipment for CAT 1 (Zone 0)requires Notified/Approved Body Certification.

- Equipment that is purely non-electrical requires a ‘technical file lodging’ with a Notified/Approved Body for CAT 2 (Zone 1) and the Notified/Approved Body will normally issue proof or receipt.

- All ‘Protective Systems’ (mitigation) require Notified/Approved Body Certification

- Associated Apparatus (even in the safe area) may require Notified/Approved Body Certification

- Simple Apparatus can be self-declared even for Zone 0 if you are competent (e.g. CompEx EX12) and produce a DSD (the DSD is effectively the Certification). Simple Apparatus must still be assessed against the appropriate Standards and appropriately marked for inspection.

It is also worth noting that electrical products which are certified as a ‘component’ (a ‘U’ on the end of the certificate number) requires recertification by a Notified/Approved body before they can be used in a potentially explosive atmosphere for CAT 1 and CAT 2.

Equipment Manufacturers Self Declaration (commonly referred to as ‘Self Certification’)

Manufacturers ‘Self Declaration’ under CE or UKCA Marking makes the person who signs the ‘declaration’ legally responsible for the equipment compliance as there is no legal requirements for 3rd party certification and no quality control over what is produced other than internal control of production. Regulatory Authorities may request the evidence (for example clause by clauses standards assessment and test reports) for the standards claimed on the Declaration.

Category 3 Electrical and Category 2 and 3 Non-electrical can be voluntarily certified (and this is sometimes required by end users/buyers) in the following ways…

- A Conformity Certificate from a Certification Body but with no Quality Control on production (so there can be no Notified/Approved Body number under the CE/UKCA Marking)

- A Unit Verification Certificate where the Certification Body inspects the equipment for compliance and lists it on the Certificate by serial number (this can be a full Notified/Approved Body Certification with the Body number under the CE/UKCA Marking)

The Requirements for IECEx

IECEx always requires a fully accredited and regulated ‘IECEx Certification Body’ to issue the certification, there is no self certification route. All IECEx Certificates also control the manufacturing quality related aspects via an IECEx QAR.

It’s easy to see why IECEx has become the ‘international’ scheme and why many end users prefer the simplicity and control of an IECEx Certificate. It should be noted however that although IECEx is the ‘baseline’ for most international schemes (including UKCA and ATEX), National Certification is normally required ‘in addition’ to the IECEx Certification, but the process should be far simpler than achieving multiple National Certification that may not be accepted in other countries…

Sean Clarke CEng MSc FIET is the Managing Director of ExVeritas who a UKCA Approved ‘Ex’ Body, an ATEX Notified Body and IECEx Test and Certification Body. With ‘Ex’ test laboratories in the UK and USA. www.exveritas.com

Many of you will be aware that the Ex-Standards aimed at ‘end users’(such as IEC60079-14) have very specific requirements for competence. These can include both ‘knowledge’ and ‘skills’ assessments and the need to retain and be reassessed regularly. ‘Installers’ have historically had to have some form of special certificationto be allowed to work in Hazardous Areas (for Example, CompEx 01-06) but it is now also the case that people involved in design and equipment selection will also be asked for their qualifications and evidence of competence.

In addition to the current requirements of the users’standards, a new standard (initially a technicalspecification) is being developed specifically covering Ex Competence (IEC TS 60079-44 Personal Competence) so now is a good time to refresh our memory on the role of the designers and project engineers!

Ex Design Competence

The requirements for personnel involved in the process of designing plant or equipment for use in potentially explosive atmospheres (including equipment that may be in the safe area but have functionality involved in the safe explosion prevention or mitigation) should be given serious consideration.

Reviewing case studies of many recent explosions will demonstrate that it was the fundamental design that was unsafe, even when correctly built and installed (such as an incorrectly specified level switch or an impractical maintenance procedure post installation).

The requirements will obviously be applicable to companies who design plant but are equally applicable to project engineering companies or manufacturers who may provide rigs, skids or assemblies (now covered by IEC TS 60079-46) that may or may not utilise certified hazardous area equipment. (ExVeritas offer specific course for ‘Assembles’ that cover these specific risks and challenges for ‘manufacturers’ as well as end users)

According to the Installation Standard, Designers must possess, to the extent necessary to perform their tasks, the following skills:

Designers must be able to demonstrate their competency and provide evidence of attaining the knowledge and skill requirements specified above, relevant to the types of protection and/or types of equipment involved. They must also be able to demonstrate their competency with documentary evidence such as ‘Designers training Certificates’ to the user and suitable documented safe operating procedures and list of required checks and maintenance (including intervals).

One of the most used and widely accepted levels of certification for Designers is CompEx EX12, it is also worth noting that CompEx has also added an introductory Functional safety course to their portfolio which is useful alongside EX12.

Full details of the new CompEx Courses can be found here: CompEx Training and Competence Certification or email This email address is being protected from spambots. You need JavaScript enabled to view it. for a prospectus.

This Article can also be found in the issue below.

Arco Professional Safety Services, the UK’s leading safety training company, has launched a new Learning Management System (LMS), offering over 50 e-learning awareness courses with the ability for customers to self-serve their health and safety training requirements. These courses, which can be completed remotely, are designed to provide a basic understanding of the various hazards that may be found in the workplace and are an ideal starting point to further, more in-depth training.

All employers have a legal obligation to ensure their employees are appropriately trained for the job they do. The Arco LMS offers a wider variety of training courses beyond the experiential training and classroom learning available at their training facilities, enabling more opportunity to implement training programmes for their workforce. Starting from just £20, courses available through the LMS platform include asbestos awareness, control of substances hazardous to health (COSHH), emergency first aid at work refresher (EFAW), fire awareness, manual handling and risk assessment. Employers can review the e-learning courses available and select those most appropriate to their needs, efficiently and cost-effectively.

The system has the potential to allow employers to create, view and manage appropriate training programmes suitable for specific individuals, roles or companies. With the support of the Arco Professional Safety Service training team, this could then be linked to a comprehensive offering including bespoke learning modules, videos, documentation, course booking options for assessing or practical application of knowledge and assessments.

Arco’s specialist instructors have a wealth of industry experience and can provide businesses with the most relevant training to help keep workers safe. Offering a wide range of courses, Arco Professional Safety Services cover training for the below disciplines, alongside the LMS system:

- Working at Height

- Confined Spaces

- Respiratory

- Health and Safety

Brian Grunes, Training Manager says: “We have a core purpose to help keep people safe at work and have developed this new Learning Management System to make it easy for business to choose, book and deliver the most appropriate awareness-based training courses for their employees. From Fire Awareness to First Aid and Ladder Safety, our comprehensive e-learning course offering is brought together in one, simple to use, online resource to help businesses maintain a safe working environment for everyone.”

CSA Group UK’s 2018/19 training programme is available to book! See our latest training offers below

CSA Group UK’s 2018/19 training programme is available to book! See our latest training offers below

CSA Group UK’s 2018/19 training programme is available to book! See our latest training offers below

Our courses cover the latest legislative requirements for the Ex market - 95% of attendees have said they would recommend a CSA Group training course to their colleagues. Hazardous Engineering Solution readers’ discount of 10% - quote HES 10 when booking our open courses*

Hazardous Areas Basic Principles course (3 days) (Read More)

CSA- Sira Launches Training Programme For 2012/13

CSA- Sira Launches Training Programme For 2012/13

CSA-Sira provides a comprehensive range of courses for those working in potentially explosive atmospheres and the environmental monitoring industry.

Training in the principles of: IEC; ATEX 94/9/EC & 137; DSEAR; IEC 61508 Functional Safety; MCERTS Environmental Monitoring (Air & Water); IECEx Certification of Personnel Competence & Competence Professional Schemes. (Read More)

CSA-Sira provides a comprehensive range of courses for those working in potentially explosive atmospheres and the environmental monitoring industry. Training covers: IEC; ATEX 94/9/EC & 137; DSEAR; IEC 61508 Functional Safety; MCERTS Environmental Monitoring (Air & Water); IECEx Certification of Personnel Competence & Competence Professional Schemes.

CSA-Sira provides a comprehensive range of courses for those working in potentially explosive atmospheres and the environmental monitoring industry. Training covers: IEC; ATEX 94/9/EC & 137; DSEAR; IEC 61508 Functional Safety; MCERTS Environmental Monitoring (Air & Water); IECEx Certification of Personnel Competence & Competence Professional Schemes.

Working in explosive atmospheres is no joke – unless, of course, it’s in a cartoon!

At PVL, we know that the right ATEX-certified pressure switch can make all the difference when it comes to protecting people, plants, and processes.

Our latest light-hearted cartoon illustrates a serious point:

✅ Certification isn’t optional

✅ Materials matter

✅ Zone suitability is critical

✅ Safe switching saves lives

Facilities maintenance operations can face different circumstantial challenges which require modern solutions. Particularly for hazardous environments such as the oil & gas and petrochemical industries, cold-curing polymeric repair and protection materials can provide a novel means of bypassing these challenges.

This application demonstrates a Customer’s use of Belzona’s cold-curing epoxy two-part structural adhesive, Belzona 7311, to navigate these challenges in the petrochemical industry to fulfil their maintenance needs.

This metal tank needed maintenance to both the base and the roof

The structural epoxy adhesive, Belzona 7311, provided a cold bonding solution for the metal substrate

What was the Problem?

A metal storage tank in a Chemical Plant containing concentrated sulfuric acid required maintenance to both the base and the roof. The Customer needed to bond pipe supports to the top of the tank to reinforce the pipes directly above. However, the tank was installed with a rubber lining, ruling out hot work such as welding as a means of attaching the pipe supports.

Meanwhile, the existing tank base coating had been exposed to chemical attack and needed to be replaced with a suitable chemical-resistant coating to protect the tank from future chemical spills.

The tank base had been exposed to chemical attack

The internal rubber linning made welding inappropiate to bond the metal pipe support

Belzona 7311: A New Cold Bonding Solution

Belzona’s first ever structural adhesive, Belzona 7311, proved to be the optimal cold bonding solution for the Customer’s requirements due to its high mechanical strength, cleavage and shear resistance. By using this technology, the supports could be cold bonded to the top of the metal tank without the associated risks of welding such as damage to the rubber lining and metal distortion known as Heat Affected Zones (HAZ). HAZ can be the result of the intense process of heating and cooling the substrate, leading to weaknesses in the metal and compromising the integrity of the weld joint.

Bonding of the Pipe Supports

The Contractor specified that the best way of attaching pipe supports was to cold bond six 254 mm by 254 mm (10 inch by 10 inch) metal plates to the top of the tank, which could then be cold bonded to the pipe supports. The chosen areas were marked with tape, before being prepared using handheld surface preparation tools. The application areas were prepared to SSPC-SP11 standard, producing a bare metal surface and a minimum 25 μm (1 mil) profile for a high level of adhesion.

The two-part epoxy adhesive, Belzona 7311, was then mixed and applied to both the substrate and the underside of the metal plates, before being held in place with no additional weight or pressure

while the product was allowed to cure. Once the plates had been cold bonded to the metal tank, the pipe supports were subsequently attached to reinforce the pipes in operation above the tank.

The metal surface was prepared to allow the plates to adhere

The epoxy 2-part adhesive, Belzona 7311, was applied to both the tank surface and the plates

The cold bonding solution was allowed to cure with no extra weight or pressure

Application of the Chemical Resistant Coating

Belzona 4311 (Magma CR1) was specified to protect the tank base due to its chemical resistant qualities, having encountered no significant deterioration after a year of immersion in up to 98% sulfuric acid at 40°C (104°F), when tested in accordance with ISO 2812-1.

The previous tank base coating was removed and the concrete surface was prepared with an ATEX-rated power tool and conditioned using Belzona 4911 (Cleaner/Degreaser) to ensure maximum adhesion for the new coating.

Two coats of Belzona 4311 (Magma CR1) were applied to provide long-term protection to the tank base, avoiding the harmful financial, safety and environmental consequences of a future leak.

Belzona 4311 (Magma CR1) was applied to the tank base

The chemical resistant coating will provide protection in the case of chemical spills

Results of the Repair

The sulfuric acid tank base will be protected against chemical attack for the long term due to the chemical resistant properties of Belzona 4311 (Magma CR1). Meanwhile, the Customer was impressed by the ability of Belzona 7311 to solve the challenges caused by the tank’s rubber lining, cold bonding the metal pipe supports securely without the need for welding. The Customer was also very satisfied by the high mechanical strength, cleavage and shear resistance demonstrated by the cold bonding solution during the application.

The strength of the cold bonding solution allowed the pipe supports to be seamlessly attached to the top of the tank

Cold Bonding Solution in Action

This application presented an example of the opportunities provided by the epoxy two-part structural adhesive, Belzona 7311 as a cold bonding solution, offering an effective and safe alternative to welding. The solution can be used for structural bonding applications requiring high mechanical strength, cleavage and shear resistance, including ladders, handrails and plate bonding, and is suitable for harsh service environments.

Abstract

When identifying solutions that can offer assurance and longevity, the maintenance and reliability of assets repairs can be challenging, this white paper will look into the use of structural adhesives as the first-choice solution.

Structural adhesives can be used for affixing metal substratesor components as they provide high modulus and high strength. However, they are not currently internationally recognised like the traditional methodseven though adhesives are already used in a wide range of industries, such as aerospace, rail, and construction.

Traditional practice such as welding, riveting, nuts and bolts and mechanical fixing are perceived as the go to method.However, they all have their inherent inadequacies. Welding can be hazardous to health, riveting,nuts and bolts concentratethe stress locally while mechanical fasteners can concentrate stress.

This paper introduces a novel, two-component, solvent-free toughened epoxy adhesive material that provides high adhesion to metallic substrates while also being able to withstand high movement or cyclic fatigue in comparison to general epoxy materials.

As well as potential application areas, the article also discussesa number of benefits, including ease of use, load bearing andimpact resistanceproperties.

Introduction

Most industrial maintenance or repair procedures can eitherinvolve welding or use of mechanical fasteners as these can be perceived as easy andquicker, however, these procedures might initially seem to correct the issue but may cause more harm than good.Depending on the repair situation for instance welding or drilling to connect mechanical fasteners on a storage tank containing flammable liquid is not recommended for obvious reasons this is where a structural adhesive can really offer a solution for that maintenance repair.

There are many structural fixings used across a whole range of industries that may be part of any maintenance or repairthese include support brackets such as cable trays, antennas, heating coils filter pans or any other internal fixtures in vessels that’s suffer from corrosion, impact orvibration damage. Within construction there are fire water deluge systems, nozzles connections, facades panels and signs which can require maintenance overtime or adverse weather conditions.

Processequipment or piping can suffer from thinning or the steel or even through wall defects which will need either monitoring or repairing depending on whether the integrity of the equipment has been lost.

Structural fittings are generally for fixing of static members but maybe subjected to forces unbeknown at time of installation this could include thermal cycling of the joints, cyclic loading or vibration due to fatigue of a component.

If there are repairs due to the above, the contractor maybe in asituation where a choice of solution can be made, then the strengths and weaknesses need identifying.

Welding is regularly used for repairs as it is widely available while being well regulated with high customer confidence and high strength of the repair it does come with its inherent risks both the use, the material by heat stressingand the user as welding can cause both acute and chronic health risks.Application of welding repairs onto live piping sections, storage tanks or process systems and equipment should not be undertakendue to the high temperatures involved and not forgetting the combustible nature of the process fluid or gasrunning through or being stored in these components.

Bolted joints are seen as simple and low cost due to the ease ofdisassembly and reassembly and these can be dissimilar metals,but the use of dissimilar metals will contribute to galvanic corrosion, add weight to the joint, requiring routine inspection and tensioning while the drilled holes in the support material, stress distribution is not uniform and concentrated at the holes.

Structural adhesives have high bond strength whilst being lightweight, adhesive applied to cover the entire joint, resulting in uniform stress distribution, reducing metal distortion under strain.

Importance of a Strong Bond

Adhesive bonding is the joining of similar or dissimilar members together while creatingpermanent high strength bonds which can transfer structural stress without loss of structural integrity.

Regardless of the joint type used, it is important to understand the different stresses that are imparted onto a bonded assembly. Adhesives perform the best when the stress is two-dimensional to the adhesive, allowing the force to be applied over the entire bond area.

Joints that are well designed for adhesives place most of the stress into compression or shear modes, adhesives perform the worst when stress is one-dimensional to the adhesive, concentrating the load onto the leading edge of the bond line. Joints placing stress into cleavage or peel concentrate the stress onto the leading edge, which may lead to premature bond failures, especially if subjected to vibration, impact or fatigue

Bonds of high strength are obtained after cleaning of the substrate by removal of any contaminants followed by the roughening of the substrate generally in the form of grit blasting to international recognised standards, this is why surface preparation is critical to success regardless of what type of adhesive is used.

There are three types of bonding that are important to achieve to ensure good adhesion. These are:adhesive, chemical, and mechanical.

Adhesive relies on surface energy to generate adhesion to the substrate. While chemical relies on chemical bond formation and electronic bonding to produce adhesion. Mechanical adhesion is due to the creation of an irregular profile that allows a deeper profile to be produced.

Thetypes of structural adhesivesavailable have been summarised in Table 1

Table 1 - Types of Structural Adhesives

There are two types of failure mechanisms associated with structural adhesives:

1. Cohesive failure occurs in the bulk layer of the adhesive material. This failure mode is limited by the strength of the adhesive material and can be caused by insufficient curing of the adhesive and applications at a greater thickness than that recommended among others.

2. Adhesive failure occurs when the mechanical adhesion between the adhesive and the parts being joined is overcome by the loading. This failure mode is associated with inadequate surface preparation, presence of contaminants, or insufficient curing of the adhesive among others.

Background

Design considerations for Belzona 7311 were based on both technical target requirements and a practicality approach, as summarised in Table 2.

Table 2 - Design Considerations

Belzona 7311 was subjected to at least the following tests and evaluation protocols in to ensure that it met the design criteria previously discussed. Where possible, internationally recognised standards were used.

Experimental Procedure

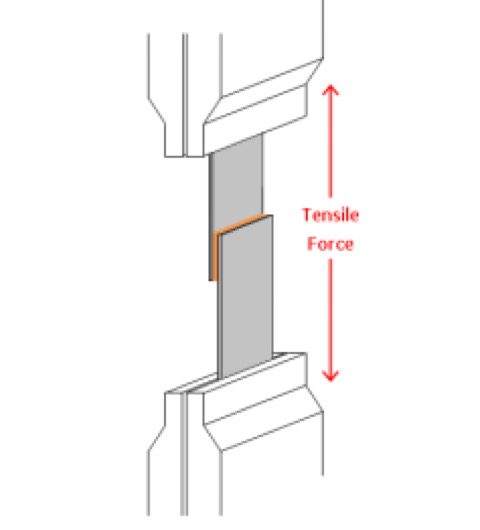

1. Cleavage Adhesion – ASTM D1062

Cleavage adhesion is used to assess the strength of an adhesive bond between two substrates when exposed to cleavage stress.

Belzona 7311 wasapplied between two identical grit blasted metallic cleavage test pieces to create a fixed bond area of 125mm² of minimal bondline thickness.

The specimen was allowed to cure then attached to a 25kN tensometer using suitable grips. The tensometer then applies a load at a fixed rate of 1.3mm/min exerting a cleavage force on the specimen until bond failure. This test is repeated five times so an average force can be calculated.

Figure 1 - Cleavage adhesion test

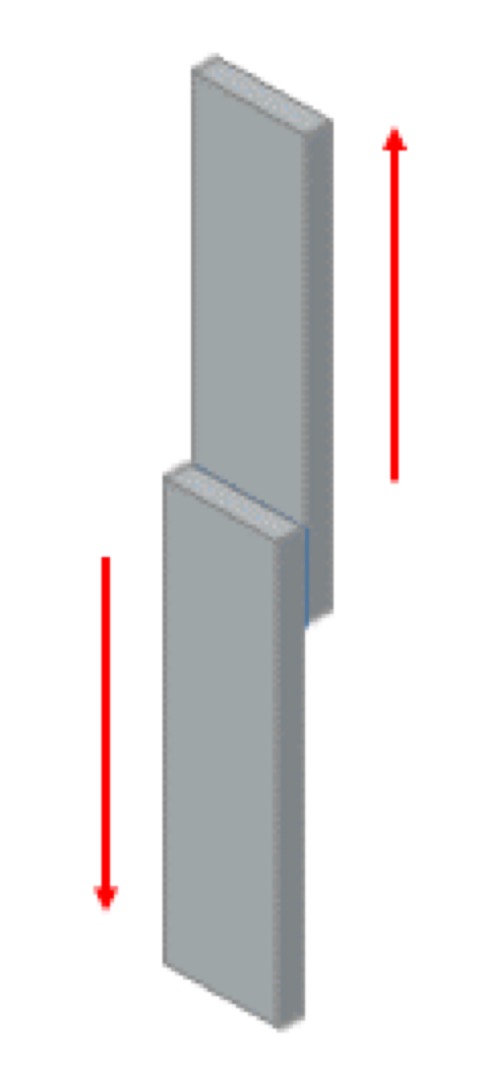

2. Tensile Shear Adhesion – ASTM – D1002

Tensile Shear Adhesion or lap shear adhesion is used to determinethe adhesive strength of a material when bonded between two ridged metallic substrates.

Samples are 100 x 25.4 x 2mm and are overlapped lengthwise by approximately 12.7mm and bonded toa minimalbondlinethickness with Belzona 7311.

The specimen was allowed to cure then attached to a 25kN tensometer using suitable grips. The tensometer then applies a load at a fixed rate of 1.3mm/min exerting a cleavage force on the specimen until bond failure.

Figure 2- Tensile force

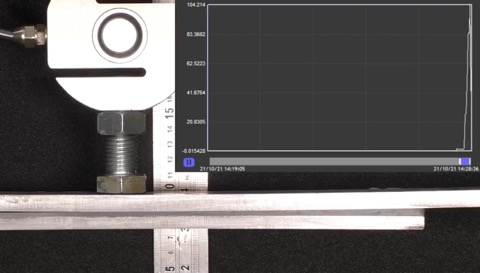

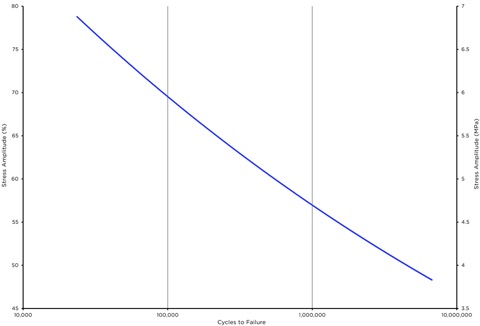

3. Fatigue Resistance – ISO 9664

Fatigue resistance is the highest stress that a material can withstand for a given number of cycles without breaking.

A standard static Tensile shear adhesion test was conducted to determine the mean breaking stress – 24.17 MPa following this 35% of the mean breaking stress value is used as the mean stress in fatigue testing - 35% mean shear stress = 8.461 MPa (24.17 MPa x 35%)

Figure 3- Tensile shear adhesion test

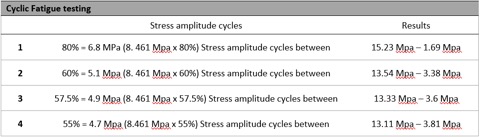

At four different alternating stresses, fatigue testing was conducted at 30Hz until failure:

Figure 4 - ISO 9664 Fatigue stress cycle

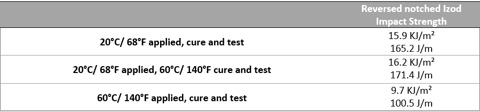

Impact tests can be used to assess the toughness of a material, a material’s toughness is a factor of its ability to absorb energy during plastic deformation. Brittle adhesives have low toughness as a result of the small amount of plastic deformation that they can endure. Tougher materials on the other hand can absorb greater energy during fracture and thus, have improved impact resistance.

The Izodimpact test allows for samples to be tested in two forms: either ‘notched’ or ‘un-notched’ in our case the testing will be notched which has a V-shaped notch of approx. 2.5mm in depth with a total defect angle of 45°in the centre of a specimen sample with dimensions of 12.7 x12.7 x 65mm. The notch concentrates stress and allows measurement of crack propagation.

Non-standard testing:

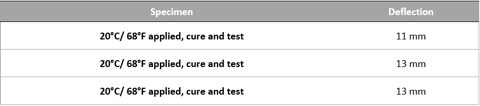

5. 3-Point Load Test

This comparative technique is used to assess the relative flexibility of adhesives when applied to a metallic substrate. In this test a mild steel panel of dissimilar dimensions

Plate 1 550 x 50 x 10 mm thick

Plate 2 225 x 50 x 10 mm thick

are stressed to the point the adhesive fails. The panel is held in position at two points, one at either end of the sample and is gradually stressed at a single point in the centre of the specimen via a hydraulic press as seen in figure 3. The greater the displacement i.e., the further the press travels until failure the more flexible the adhesive. The thickness of the adhesive will influence the degree of flexibility so analysis should be duplicated for repeatability purposes. In the case of this testing at the manufacturing stage the specimens were compressed by hand pressure only, to try and replicate ‘in field’ applications of achieving below the maximum bondlinethickness of 2mm.

Figure 5– 3-Point Load Testing

Testing Results and Discussion

1. Cleavage Adhesion – ASTM D1062

Table 3 - Cleavage Adhesion Results - ASTM D1062

2. Tensile Shear Adhesion – ASTM – D1002

Table 4 - Tensile Shear Adhesion Results– ASTM D1002

3. Tensile Fatigue Resistance – ISO 9664

Table 5 - Cyclic Fatigue Testing Results

Figure 6 - Belzona 7311 SN Curve

From a mean breaking stress of 35% (8.461 Mpa), Belzona 7311 will survive 106 cycles at 56.6%, with an alternating stress amplitude of ± 4.791 Mpa = 13mpa to 3.67 Mpa

4. Impact Resistance – ASTM D256

Table 6 - Impact Resistance Results – ASTM D256

5. 3-Point Load Test

Table 7– 3-Point Load Test Results

Figure 7–3-point load Specimen Testing

Conclusions

Several conclusions can be drawn from the use of Belzona 7311 as a solution for the repair or maintenance of assets:

Figure 8 - Structural adhesive, Belzona 7311, used to bond bracket

Please click here for more information about Belzona 7311.